MBN 10143_2002_EN

August 2002

Mercedes-Benz

Screws with external hexalobular driving

feature

with large flange

MBN 10 143

Observe list of approved suppliers

Supersedes

edition: 2001-12Supersedes

DIN 34801

Continued on pages 2 to 4

Issued by:

DaimlerChrysler AG D-70546 Stuttgart

Standards (EP/QIN)

Technical responsibility (Name): D?rfel

Department: EP/QIN Plant:019Telephone: (+49) 711 17- 3 35 21HPC:D652Sequence number 14 071

Confidential! All rights reserved. Distribution or copies without written agreement by DaimlerChrysler AG prohibited.

Contractors may only receive standards through the responsible purchasing department.

Scope

This standard contains specifications for screws with external hexalobular driving feature and large flange with coarse and fine pitch thread and nominal thread diameters from 5 mm to 20 mm, with property classes 8.8 and 10.9 in product grade A and with nominal thread diameter from 4 to 12 mm made of Al9, Al10.

The gauge dimension of the external hexalobular driving feature is specified in MBN 10 144.

Approval of procurement sources

All Torx licensees of the Camcar Division of Textron lnc., USA, shall have unrestricted approval.

Other manufacturers wishing to be granted approval shall ensure that their products comply with the licensee's technical requirements. Product testing is required.

The approval of procurement sources applies to parts manufactured from aluminium alloys.

Page 2

MBN 10 143 : August 2002

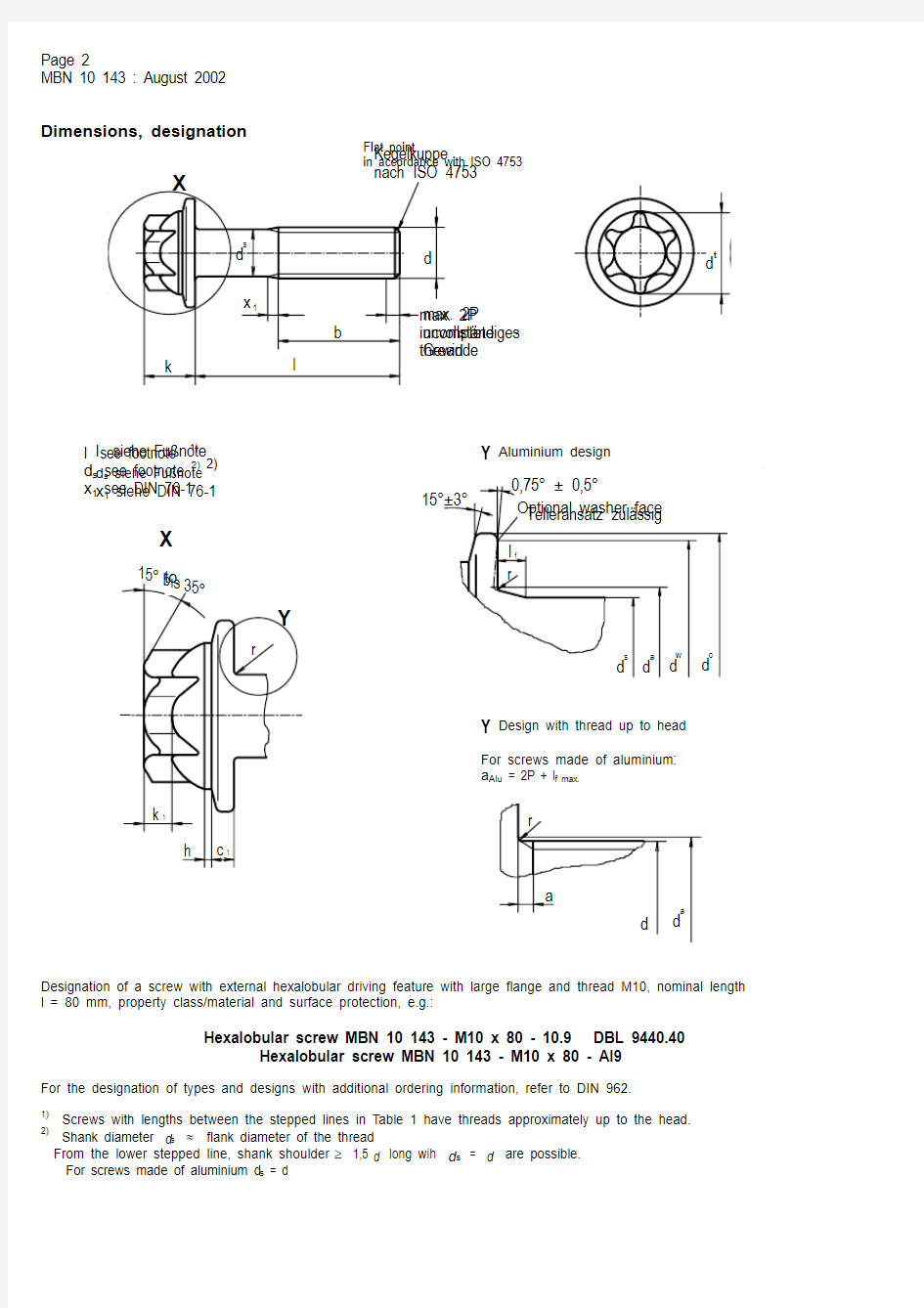

l siehe Fu?note Y Aluminium design

d s sieh

e Fu?note 2)

x 1

siehe DIN 76-1

Y Design with thread up to head

For screws made of aluminium :a Alu = 2P + l f max.

Designation of a screw with external hexalobular driving feature with large flange and thread M10, nominal length l = 80 mm, property class/material and surface protection, e.g.:

Hexalobular screw MBN 10 143 - M10 x 80 - 10.9 DBL 9440.40

Hexalobular screw MBN 10 143 - M10 x 80 - Al9

For the designation of types and designs with additional ordering information, refer to DIN 962.

1) Screws with lengths between the stepped lines in Table 1 have threads approximately up to the head.2)

Shank diameter d s ? flank diameter of the thread

From the lower stepped line, shank shoulder 3 1,5 d long wih d s = d are possible. For screws made of aluminium d s = d

X

d a

a

r

d

l see footnote

1)

d s se

e footnote 2)x 1 see DIN 76-1

Page 3

MBN 10143 : August 2002 Table 1

Thread size d M5M6M7M8

(M8x1)

M10

(M10x1)

(M12)

M12x1,5

(M14)

M14x1,5

(M16)

M16x1,5

(M18)

M18x1,5

(M20)

M20x1,5

P Coarse th.0,8111,251,51,75222,52,5

a max.2,4333,754,55,25667,57,5

b Nominal40505565808080808080

min.1,451,752,12,653,604,105,105,506,006,50 c1

max.1,702,002,52,903,904,405,405,806,406,90 d a max.5,706,807,89,2011,2013,7015,7017,7020,2022,40 d c max.11,8014,2015,817,9021,802629,9034,5038,6042,80 d w min.9,8012,2013,8015,8019,6023,8027,6031,9035,9039,90

max.6,507,50810,0012,0014,0016,0019,0021,5024,00 k

min.6,257,257,759,7511,7513,7515,7518,7521,2523,75 k1min.1,802,002,253,103,703,904,506,107,108,70 h max.0,900,900,900,901,301,301,301,301,401,40 l f Alu max.1,41,41,41,92,12,8----

r min.0,200,250,30,400,400,600,600,600,600,80 External hexa-

lobular driving

feature size

E8E10E10E12E14E18E20E24E28E32

Lenght l

10

12

16

20

25

30

35

40Thread approximately up to head 1)

45

50

55

60

65

70

80

90

100

110

120

130

140

150

160

180

200

Page 4

MBN 10 143 : August 2002

Technical delivery conditions

Table 2

Material

Steel

Aluminium alloy

General

requirements International standard DIN ISO 8992

Tolerance

6 g

International standard ISO 261, ISO 965-2

Property class (Material)8.8, 10.9Al9; Al10Standard

DIN EN ISO 898-1

MBN 8839Product grade A

International standard

DIN EN ISO 4759-1

Surface protection in acc. with DBL9440

Bright + coated with sliding compound

Finish

Surface roughness is covered in DIN 267 Part 2

Limits for surface discontinuities are covered in DIN EN 26 157 Part 1 and Part 3

Acceptability

For acceptance procedure, see DIN ISO 3269 and MBN 10 168.

Thread rolling screws (made of steel)

- Case hardened and tempered thread rolling screws

Mechanical and performance requirements in accordance with DIN EN ISO 7085Designation example:

Hexalobular screw MBN 10 143 - M8 GFx 60 DBL 9440.40

- Quenched and tempered thread rolling screws DUOTAPTITE

Mechanical and performance requirements in accordance with MBN 7085-2Designation example:

Hexalobular screw MBN 10 143 - M8 DTx 64 - 10.9 DBL 9440.40

Length grading in accordance with MBN 7085-2 Table 4.

Matrix of characteristics

For hexalobular screws in accordance with this standard, matrix of characteristics MBN 4000-2-1.1 shall apply.For thread rolling screws matrix of characteristics MBN 4000-2-1.11 shall apply.

Changes

-Thread size M7 adopted.

Thread

Limit deviations and geometrical tolerances

Mechanical properties