Wet sliding friction of elastomer compounds on a rough surface under varied lubrication conditions

Wear262(2007)

707–717

Wet sliding friction of elastomer compounds on a rough

surface under varied lubrication conditions

Xiao-Dong Pan?

Bridgestone Americas Center for Research and Technology,1200Firestone Parkway,

Akron,OH44317-0001,United States

Received28February2006;received in revised form1August2006;accepted3August2006

Available online18September2006

Abstract

‘Green’tire bearing tread rubber reinforced with precipitated silica can exhibit improved wet traction performance.The underlying mechanism is currently not well understood.To improve our capability of rational material design for enhanced driving safety,wet sliding friction for various rubber compounds is tested on a Portland cement concrete surface under varied lubrication conditions.The wetting liquid is either ethanol or water,and the initial amount of liquid on the concrete surface is adjusted.Sliding friction is detected to alter with lubrication condition.Under ethanol lubrication,the sliding friction is markedly lower than that under water lubrication.Additionally the bene?t in wet traction from silica is signi?cantly diminished or eliminated in ethanol.Such observations cannot be rationalized with simple considerations of rubber bulk viscoelasticity, liquid viscosity,cavitation,or capillary effect.We believe that these observations strongly indicate the signi?cance of interfacial interactions in determining the wet sliding friction of elastomer compounds.The potential relevance of capillary porosity in concrete and Marangoni drying effect to wet traction is also introduced.

?2006Elsevier B.V.All rights reserved.

Keywords:Elastomer;Wet sliding;Friction;Silica;Water;Ethanol

1.Introduction

In order to stop a moving automobile on a highway wetted by rain,a maximal level of sliding friction from tires is obviously desired upon brake application.At low sliding speed before the emergence of elastohydrodynamic lubrication,other than the tread pattern,material properties of tread rubber compounds play a signi?cant role in determining the wet traction performance of a pneumatic tire.

Tread rubber compounds are made of crosslinked elastomers reinforced with?ne?ller particles.The conventional?ller has been carbon black derived from fossil fuel.Starting from the early1990s,precipitated silica used along with silane has become popular in preparing the so-called‘green’tire[1].In comparison to carbon black-?lled rubber,silica-reinforced rub-ber can lead to simultaneous reduction in fuel consumption and enhancement in wet grip while maintaining wear resis-?Tel.:+13303797339;fax:+13303797530.

E-mail address:panxiaodong@https://www.sodocs.net/doc/031627142.html,.tance.Such unexpected gain in the combination of performance

characteristics has spurred renewed interests in fundamental

understanding on mechanisms of wet sliding friction.

For tribological systems consisting of rubber sliding on a

rough road surface with water in-between,factors affecting the friction characteristics have been recognized[2–4].During slid-

ing,the multi-scale asperities on road surface induce high fre-

quency dynamic deformation of rubber.Viscoelastic dissipation

of energy inside rubber is considered as the primary contributor

to sliding friction[5].Coef?cient of frictionμdepends on the

so-called reduced variable a T·v.Here the temperature dependent a T is the well-known Williams–Landel–Ferry time–temperature

shifting factor[6]while v is the sliding speed.In comparison,the

load exerts much less sensitive impact on friction[4].Quantita-

tive analysis of rubber friction certainly requires proper account

of the typically nonlinear viscoelasticity for rubber compounds,

the speci?c roughness characters for the road surface,as well

as effects from friction heating at high v.Though not yet well

explained,testing of‘veneered’rubber compounds indicates the

importance of the thin surface layer of rubber in determining wet

sliding friction[7,8].

0043-1648/$–see front matter?2006Elsevier B.V.All rights reserved. doi:10.1016/j.wear.2006.08.003

708X.-D.Pan/Wear262(2007)707–717

Without interference from surface charge[4],remaining contribution from adhesion(or adhesion hysteresis[9–11])is detectable(embodied as the presence of a hump along a friction master curve).Possible impact from the chemical nature of road surface has rarely been assessed[3].In the presence of sharp surface asperities,tearing of rubber can further enhance friction [12].Even though intuitive concern on possible change in rhe-ological behavior of extremely thin water?lm was raised[13], viscous dissipation within the remaining water?lm is generally considered insigni?cant.

Some detailed studies have been performed for the case of smooth rubber on a wet smooth glass surface.Summarizing variation of friction with dynamic lubrication conditions,some Stribeck curves were established[14].The?ne details of extru-sion of liquid between the rubber and the glass surface were examined with the method of optical interferometry[15].Under proper conditions during sliding,waves of rubber detachment (Schallamach waves)were observed[16].Under both non-sliding and sliding conditions,the process of interfacial energy-driven dewetting has also been studied[17–20],including the situation where there exists single defect on the glass surface.

A smooth glass surface is certainly much less complicated than a realistic highway surface.Other than the multi-scale asperities on the road surface,a piece of typical Portland cement concrete can have porosity of10–20%[21].Thus the road sur-face can be leaky.Even though possible implications of capillary porosity to liquid extrusion,viscous energy dissipation,and rewetting of surface are completely ignored in recent literature, there is an earlier investigation of dynamic permeability of pave-ments[22].

Facing such multitude of factors,the dif?culty in predicting the likely level of friction of rubber components in engineering practice has been realized[23].Recently,quantitative modeling of rubber friction on a fractal surface has been presented based on bulk viscoelastic description of material behavior[24,25]. Among the many proposals attempting to rationalize the bene?t in wet traction from silica,the existence of a softer skin at the sliding interface for silica-?lled rubber appears plausible[26]. The stress-softening effect can be stronger for silica-?lled rubber than that for carbon black-?lled rubber.However,practitioners also reported discrete singular observation that the bene?t in wet traction from silica disappears on a surface lubricated with ethanol[27].

Obviously establishing a complete set of phenomenology is essential for achieving a true understanding on friction mecha-nisms,which is the main purpose for this study.Here wet sliding friction for various rubber compounds is tested under different lubrication conditions with a portable British Pendulum Skid Tester(BPST)[28,29].A Portland cement concrete patio block provides the road surface.The concrete surface is wetted with either ethanol or water.Due to the current absence of ef?cient method for accurate quanti?cation of water?lm thickness on a rough surface,the lubrication condition is further adjusted by generating visually different amount of liquid on the surface before any sliding test.

With the BPST,a rubber slider attached to the end of the swinging arm slides on the road surface for a?xed length of path.During sliding,kinetic energy of the swinging arm is con-sumed to overcome the sliding friction.Consequently after the slider comes off contact with the road surface,the initial releas-ing height of the arm cannot be regained.The instrument reading, British Pendulum(Tester)Number or BPN,corresponds to such lost in height and hence indicates the level of sliding friction. Approximately BPN is of order of100×μ,hereμis the coef-?cient of friction[30].Hence it is more sensitive to use BPN to display the variation of friction with lubrication condition.

It is dif?cult to quantify the dynamic contact condition for BPST.However,effects from a variety of factors on wet skid resistance of rubber compounds have been revealed with BPST [30–34].The designed average contact pressure during sliding for BPST is of order of0.21MPa[28],similar to the nominal pressure between a passenger tire and road.However,the local contact pressure between rubber and sharp surface asperities can reach well beyond10MPa[35].The rubber slider moves at about 2.7m/s(or9.7km/h)when it?rst makes contact with the surface. At such sliding speed,the shear rate in a thin water?lm of1nm thickness on a smooth surface is of order of109s?1.The relax-ation rate of bulk water molecules is of order of1012s?1[36].

The lubrication behavior of extremely thin liquid?lms con-?ned between molecularly smooth surfaces has been quan-titatively examined with various Surface Force Apparatuses (SFA)[37–39].The contact pressure encountered in SFA can be3–5MPa[36].Current experimental evidences indicate that when con?ned between hydrophilic surfaces,the?uidity and lubricity of water remains down to one single layer of molecules [40,41].With a different experimental technique,ordering of liquid alkanes con?ned between an elastomer and a sapphire substrate has recently been reported[42].

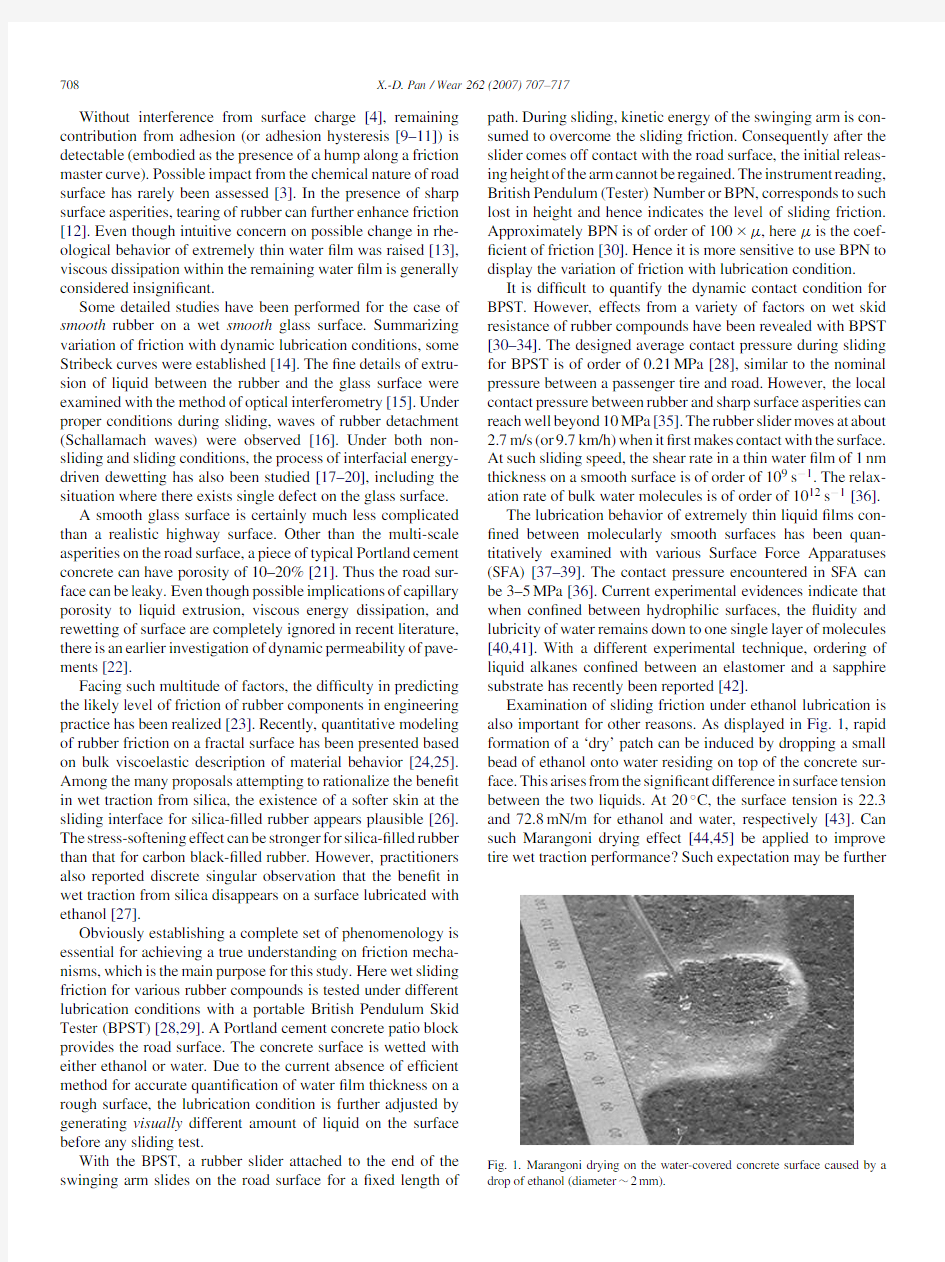

Examination of sliding friction under ethanol lubrication is also important for other reasons.As displayed in Fig.1,rapid formation of a‘dry’patch can be induced by dropping a small bead of ethanol onto water residing on top of the concrete sur-face.This arises from the signi?cant difference in surface tension between the two liquids.At20?C,the surface tension is22.3 and72.8mN/m for ethanol and water,respectively[43].Can such Marangoni drying effect[44,45]be applied to improve tire wet traction performance?Such expectation may be

further Fig.1.Marangoni drying on the water-covered concrete surface caused by a drop of ethanol(diameter~2mm).

X.-D.Pan/Wear262(2007)707–717709

enhanced by the following observation[3,14].For a smooth rubber sliding(at small v)on a wet smooth glass surface,in the boundary lubrication regime,the friction under alcohol lubri-cation is higher than that under water lubrication.This was attributed to the absorption of alcohol into the rubber.A larger contact area was resulted from the softened swollen rubber.For paraf?n alcohols of varied hydrocarbon chain length,friction maximize at octanol.In contrast,on a Perspex(polymethyl-methacrylate)surface,ethanol becomes a better lubricant[46].

2.Experimental methods

2.1.Materials

Even though rubber compounds prepared with elastomers exhibiting quite different glass transition temperature T g have been tested,in this report we focus primarily on results obtained for four compounds made of a tin-coupled styrene–butadiene rubber(SBR,random copolymer)with T g at?29.5?C(Duradene739from Firestone Polymers).Here the midpoint T g is identi?ed via the differential scanning calorime-try(DSC)characterization at the heating rate of10?C/min.The microstructure of polymer molecules was revealed with nuclear magnetic resonance(NMR)test:21.0%bound styrene(by weight),47.3%1,2-butadiene content,and31.7%1,4-butadiene content.The gel permeation chromatography(GPC)tests indi-cated a weight-average molecular weight of411.9×103g/mol, a polydispersity index of1.59,and a total coupling of60.3% including a thermal coupling of11.8%.

The four compounds include a gum compound containing no ?ller,a carbon black-?lled compound,a silica-?lled compound prepared in the absence of silane,and a silica-?lled compound prepared in the presence of silane Si69.In the following they are denoted as SBR-G,SBR-C,SBR-SiO2,and SBR-SiO2-Si69, respectively.The compounding formula is shown in Table1. The?lled compounds contain50phr(part per hundred rubber, by weight)of?ller.

Carbon black of grade N339was used in SBR-C while amorphous precipitated silica(Hi-sil190G from PPG Indus-tries)was used in the silica-?lled compounds.The typical pri-mary particle size according to electron microscopy is between 26and30nm for N339,and is averaged at17nm for Hi-Sil 190G.The nitrogen-adsorption surface area(according to the Brunauer–Emmett–Teller equation)for N339and Hi-Sil190G is96and215m2/g,respectively.

In preparing SBR-SiO2-Si69,5phr of liquid organosilane bis(3-triethoxysilylpropyl)tetrasulfane(Si69from Degussa)was added during remill.In the absence of silane,to compensate for potential loss of sulfur due to its adsorption onto silica surface, a larger amount of sulfur was incorporated into SBR-SiO2to achieve a suf?cient level of crosslinking.This,in addition to the strong inter-particle hydrogen bonding(arising from hydroxyl groups on silica surface),makes SBR-SiO2the hardest com-pound.Considering the essential difference in surface chemistry between carbon black and silica,as well as the role of coupling from the silane Si69,the bonding between matrix polymer and ?ller particle surface is very different among the three?lled compounds.

Some typical characteristics for the four compounds are listed in Table2.The tensile testing was performed with a model4501 Instron Universal Testing Instrument.Viscoelastic behavior for the compounds was examined with two Advanced Rheomet-ric Expansion Systems(from Rheometric Scienti?c)[34].To examine the extent of absorption of ethanol into the rubber com-pounds,for each compound,four rectangular specimens were immersed into ethanol.Each specimen was about1.9mm thick and weighted about1.0g.The ethanol was replaced after24h of immersion.The wet weight was obtained for two specimens after72h of immersion and for the other two specimens after 144h of immersion.Each specimen was subsequently dried for24h in a vacuum oven heated to about60?C and its dry weight was acquired.The total swelling is calculated as the dif-ference in wet weight and dry weight normalized by the dry weight.

Table1

Compounding formulas

Mixing stage In phr SBR-G SBR-C SBR-SiO2SBR-SiO2-Si69 Master batch SBR100100100100

Carbon black05000

Silica005050

Stearic acid2222

6PPD a1111

Remill Si69b N/A005

Final batch Zinc oxide3333

DPG c0.50.50.70.7

MBTS c1111

TBBS c0011

Sulfur 1.3 1.3 3.0 1.15

Total108.8158.8161.7164.85

a The antidegradant6PPD is N-(1,3-dimethylbutyl)-N -phenyl-p-phenylenediamine.

b The bifunctional,sulfur-containing organosilane Si69is bis(triethoxysilylpropyl)tetrasulfane.

c The vulcanization accelerators DPG,MBTS,an

d TBBS represent diphenyl guanidine,dibenzothiazyl disul?de,and N-tert-butyl-2-benzothiazyl sulfenamide, respectively.

710X.-D.Pan/Wear262(2007)707–717

Table2

General characteristics for the cured compounds

SBR-G SBR-C SBR-SiO2SBR-SiO2-Si69 Filler volume fraction a(%)0.019.717.917.4

Midpoint T g(?C)?25.8?24.7?21.6?24.7 Temperature at peak tanδb(?C)?16.0?16.0?14.0?16.0 Tensile test at RT Strain rate during testing at0.282s?1

Stress at break(MPa) 1.9322.116.620.1

Strain at break(%)381.2437.3325.6424.7

Stress at200%strain(MPa) 1.147.729.887.52

Modulus at200%strain(MPa)0.350 5.18 5.02 4.33 Dynamic strain sweep test c Tested at1Hz,values below taken at the strain amplitude of11.8%

(1)At RT

(1.1)G at RT(MPa)0.627/0.643 2.52/2.56 5.38/5.43 2.68/2.79

(1.2)tanδat RT0.0720/0.07250.141/0.1440.190/0.1880.153/0.156

(2)Temperature d?C?14.2?13.4?11.1?13.0

(2.1)G (MPa) 3.86/4.1012.6/12.920.3/21.112.5/12.9

(2.2)tanδ 1.82/1.83 1.32/1.32 1.11/1.11 1.33/1.31

(3)Temperature e(?C)?14.7?14.0?11.7?13.5

(3.1)G (MPa) 4.0313.419.712.7

(3.2)tanδ 1.88 1.36 1.21 1.40

(4)At?14.2?C f

(4.1)G (MPa) 3.57/3.8013.523.413.3

(4.2)tanδ 1.81/1.78 1.37 1.30 1.44

Total swelling g(wt.%)Sample weight~1.0g,thickness~1.9mm

(1)After72h in ethanol 2.73 1.83 2.78 2.37

(2)After144h in ethanol 3.50 2.28 3.10 3.26

a Calculated according to the formula in Table1,taking1.8and2.0g/cm3as the density for carbon black and silica,respectively.

b From dynami

c temperature step test at1Hz with the strain amplitude at0.20%.

c Two samples teste

d under som

e conditions to check reproducibility.

d Determined via th

e method o

f time–temperature shifting,correspondin

g to BPST testing at20.9?C[34].

e Corresponding to BPST testing at19.2?C for demonstration o

f sensitivity.

f Tested after completion of all previous dynamic strain sweep tests.

g Two rectangular samples tested for each compound.

By itself,the rubber grade carbon black is hydrophobic while the precipitated silica is hydrophilic.The matrix elastomer is hydrophobic while the concrete surface is hydrophilic.The silanized silica becomes hydrophobic and thus compatible with the matrix elastomer.Both the rubber compound surface and the road surface are physicochemically heterogeneous.

2.2.Testing of wet sliding friction

Results reported here were obtained under ambient condi-tions with the room temperature(RT)in the range between23.0 and24.8?C.To remove possible residual mold release agent, the sliding edge of the rubber sliders was wiped with acetone at least1h before testing.BPST testing was performed for all the compounds in ethanol(anhydrous from AAPER)?rst.With-out being moved,the concrete block went through air-drying and extensive washing with water before further BPST testing under water lubrication.De-ionized water was then added for testing of wet sliding friction.Videos and pictures related to BPST testing were recorded with a digital camera(Canon Pow-erShot A620).For each compound,two sliders were tested under ethanol lubrication and two different sliders were tested under water lubrication.

The concrete block has the dimensions of approximately 20.2cm×20.3cm×4.4cm.By examining the difference in weight between the wet block soaked with water and the block after thorough air-drying,the volume fraction of capillary porosity is estimated to be12.6%.Prior to this study,the testing surface has been exposed to a substantial amount of testing of wet friction.

As displayed in Fig.2,the varied lubrication conditions investigated consist of the visually different initial amount of liquid present on the concrete surface before any sliding test. Corresponding to Fig.2a–c,in the following,these different lubrication conditions are referred to as Condition A,Condition B,and Condition C,respectively.A large portion of the con-crete body is immersed in the liquid.To avoid accumulation of possible wear debris of rubber on the testing surface,the sur-face was refreshed in the presence of suf?cient amount of liquid with a brush bearing soft stainless steel hair.The diameter of an individual bristle is about120?m.Unless otherwise noted,such surface agitation was consistently applied before every sliding test and the hair did become gradually worn away from brushing.

Concerning Condition A,the relatively thick layer of liquid on the surface was formed by adding extra liquid after brushing. Previous BPST testing reported was all performed under this

X.-D.Pan/Wear262(2007)707–717

711

Fig.2.Different wet state of the concrete surface before friction testing.(a)Con-dition A:covered with a relatively thick layer of water.(b)Condition B:covered with a relatively thin layer of water.(c)Condition C:only the residual amount of water remaining.(d)Almost dried after overnight air-drying as a comparison.condition[32–34]for closer simulation of realistic concern.The obviously thinner layer of liquid on the surface for Condition B was formed by gently brushing off the extra liquid from the surface.After one sliding test under Condition B,a few sliding tests were performed consecutively without any other action to the surface.Such surface state corresponds to Condition C.For comparison purpose,a partially dried surface after air-drying for overnight is shown in Fig.2d.

3.Results and discussion

Under an imposed sinusoidal deformation of small amplitude at the frequency of f0,the variation of elastic modulus G and loss tangent tanδwith temperature T was measured(Fig.3a).Loss tangent,characterizing the viscoelastic loss property,exhibits a distinct peak at the center of the transitional zone between the glassy state and the rubbery state.The temperature at the peak of tanδ,T Peak tanδ,varies with f0.Wet sliding friction for compounds very similar to SBR-G and SBR-C were previously tested for0 When the rubber slider slides across the surface bearing dif-ferent initial amount of water,the extent of water splashing is obviously different(Fig.4).Under Condition A,after the rubber slider leaves the surface,the patch swept out by the rubber slider Fig.3.Similarity in temperature dependency between bulk viscoelastic loss and wet sliding friction.(a)Variation of the elastic modulus G and the loss tangent tanδwith temperature.These are obtained under an imposed sinusoidal strain at the frequency of f0=0.01Hz and with the strain amplitude at0.20%.The temperature at the peak of tanδ,T Peak tanδ,is?23.3and?23.0?C for SBR-G and SBR-C,respectively.(b)Variation of BPN with temperature reported previously for similar compounds[32].Reinforcing carbon black of different grade(N339vs.N121)was employed for preparing SBR-C in the two plots. 712X.-D.Pan/Wear262(2007)707–717 Fig.4.The rubber slider(for SBR-C)striking the concrete surface during the pendulum skid testing.(a)A schematic plot of the portion of the pendulum swinging arm bearing the rubber slider.(b)Corresponding to Fig.2a.(c)Cor- responding to Fig.2b.(d)Corresponding to Fig.2c. Fig.5.Rewetting of the patch on the concrete surface swept out by the rubber slider(for SBR-C).The starting condition is that shown in Fig.2a.(a)Right after the slider comes off contact with the concrete.(b)A short moment later. (c)The shrinking‘dry’patch.(d)Complete disappearance of the‘dry’patch. The time interval from(a)to(c)is about1s.The‘dry’patch almost completely disappeared in2s from(a). X.-D.Pan/Wear262(2007)707–717 713 Fig.6.Wet sliding friction detected under varied lubrication conditions.(a)For the gum compound with the surface wetted with either water or ethanol.(b)For all the reinforced compounds with the surface wetted with water.(c)For all the reinforced compounds with the surface wetted with ethanol. becomes quickly rewetted in just a few seconds(Fig.5).After repeated testing under Condition C,the surface remains visu-ally wet.Discussion on the?ne difference between wet and dry surface was made long ago[47].It was noted that even a‘dry’surface may still be covered with adsorbed water up to the limit of invisibility at about500?A.The possibility of boiling away of such thin water?lm from friction heating at large sliding speed was recognized. In Fig.6,the time sequence of BPN collected for each com-pound under varied lubrication conditions is displayed.Here two samples were tested for each compound with good reproducibil-ity.The?rst12and the?nal4sliding tests were performed under Condition A.In between there were four sliding tests under Con-dition B and four sliding tests under Condition C.For testing under Condition C,the time interval between two consecutive tests was about8s. Even though it is not dramatic,the impact on sliding friction from the initial amount of liquid on the concrete surface is always detected.It has been pointed out that at low sliding speed(less than about30km/h)the hydrodynamic buildup of liquid between rubber and road surface is negligible[48].However,we hope that the detected variation can offer clues to the understanding of energy dissipation mechanisms during wet sliding. When the lubricating liquid is changed from water to ethanol, however,the sliding friction becomes markedly reduced for all the compounds.Consequently,the attempt to enhance friction under water lubrication via the Marangoni drying effect is unsuc-cessful.The sliding edge for the slider was smeared with a paper towel soaked with ethanol or the more absorbing acetone.No increase in BPN was observed under Condition A.In fact,small negative impact was observed. If considering that ethanol may be absorbed into the com-pound and results in a softened compound,the observed reduced friction is just opposite to such reasoning.In fact,after immer-sion in ethanol for over144h,the absorption of ethanol into the compounds is most for SBR-G at3.5%by weight(Table2). Other compounds prepared with polymers of widely different T g(≤?29?C,not including butyl rubber)were also tested under ethanol lubrication.Under ambient testing condition,BPN in water increases with increasing T g.Such a trend is retained in ethanol. During BPST testing the system is in a highly non-equilibrium state.The constant agitation to the liquid during testing increases evaporation of liquid and consequently grad-ually lowers the liquid temperature.For one series of testing under water lubrication,RT was between24.1and24.8?C, the initial water temperature was at22.6?C.After over2h of testing,temperature for water surrounding the concrete block became20.0?C.In contrast,for one series of testing under ethanol lubrication,RT was between23.4and23.5?C,the initial ethanol temperature was at20.4?C.After about2h of testing,the ethanol temperature became15.0?C.Temperature on the con-crete surface may be even lower.Under water lubrication,BPN for compounds made of a low-cis polybutadiene(T g=?90.4?C) increases gradually with decreasing T[33].However,BPN for such compounds still becomes markedly lower when tested in ethanol under ambient condition.Thus the reduced friction from ethanol lubrication is unlikely explained from bulk viscoelastic consideration. The viscosity of water is1002and1793?Pa s at20and 0?C,respectively.The viscosity of ethanol is1201,1317and 1786?Pa s at19.2,14.5and0?C,respectively[49].As dis-played in Fig.3b for the compound SBR-G,when T is decreased from20to about0?C,the wet sliding friction is only reduced by about5BPN units.Thus the reduction of about10BPN units in sliding friction for SBR-G under ethanol lubrication cannot come from the higher ethanol viscosity under the testing condi-tions employed. For consideration of possible cavitation based on the simplis-tic conventional criterion,the vapor pressure for water is2.34and 6.63kPa at20and38?C,respectively.The vapor pressure for ethanol is5.81and4.27kPa at20and15?C,respectively.Under water lubrication,when T is increased from20to about40?C, BPN for the compound very similar to SBR-C remains essen-tially unchanged(Fig.3b).As reported earlier[33],the bene?t in wet traction from silica under water lubrication persists in the same temperature range.Therefore,the vapor pressure at15?C 714X.-D.Pan/Wear262(2007)707–717 for ethanol cannot explain the signi?cantly reduced sliding fric-tion under ethanol lubrication. Under the lubrication of the same initial amount of water (Fig.6b),the sliding friction for both silica-?lled compounds is markedly higher than that for the carbon black-?lled compound. Even comparing across testing under the lubrication of different initial amount of water on the concrete surface,on average,BPN for SBR-C under Condition B is still lower than BPN for SBR-SiO2and SBR-SiO2-Si69under Condition A by1.5and3.8, respectively.In contrast,under the lubrication of the same initial amount of ethanol(Fig.6c),the enhancement in wet sliding friction from silica is much reduced for SBR-SiO2-Si69and eliminated for the harder SBR-SiO2. From tensile testing at RT(Table2),the modulus at200% strain for SBR-C is higher than that for SBR-SiO2-Si69.This is partially due to the fact that the density for silica is slightly higher than that for carbon black,thus at the same?ller loading of50phr(by weight),the actual volume fraction of?ller is lower for SBR-SiO2-Si69.A compound was prepared with the same SBR,in the presence of Si69,but with the amount of silica increased to match the?ller volume fraction for SBR-C.The modulus at200%strain for this compound is higher than that for SBR-C.Under water lubrication,BPN for this compound under Condition A is slightly lower than BPN for SBR-SiO2-Si69under Condition A(by1.1),but still markedly higher than BPN for SBR-C under Condition B(by2.7). Comparing SBR-SiO2to SBR-SiO2-Si69,there exists obvi-ous difference in modulus(Table2),some quantitative difference in wet sliding friction is also detected(Fig.6).This indicates that for compounds?lled with the same kind of?ller,change in viscoelastic characters is expected to result in corresponding variation in wet sliding friction.Values of the conventional vis-coelastic predictor for wet traction,tanδ,are listed in Table2 for all the compounds.The dynamic strain sweep tests were performed at1Hz and at low temperature determined with the method of time–temperature shifting,assuming that the domi-nant frequency of material deformation during BPST testing is at104Hz[34].Value of tanδis somewhat arbitrarily taken at the speci?c strain amplitude of11.8%for all the compounds.From Table2,the predictor from bulk viscoelastic measurement can-not account for the difference in wet sliding friction under water lubrication that arises from the usage of different?ller particles. After completion of the testing displayed in Fig.6,the wear scar at the sliding edge of the rubber sliders was examined under a stereo optical microscope.Pictures of the wear scar are shown in Fig.7for all the compounds.Clearly,the wear scar on the sliders tested under ethanol lubrication is less severe than that on the corresponding sliders tested under water lubrication.Thus the lower wet sliding friction detected under ethanol lubrication is accompanied with a less severe wear at the sliding edge of the slider. Based on the discussions above,the eliminated bene?t in wet traction from silica under ethanol lubrication cannot be explained with simple considerations of liquid viscosity,cav-itation,capillary effect,or rubber bulk viscoelasticity.However, such effect from ethanol lubrication does resemble strongly fea-tures of interfacial interactions in a liquid medium revealed Fig.7.Wear scar at the tested edge for the rubber sliders subjected to the testing displayed in Fig.6.Relative to the slider,the road surface moves along the arrow direction.The division on the ruler indicates1mm. X.-D.Pan/Wear262(2007)707–717715 with an atomic force microscope(in the absence of sliding) [50,51].Related to hydrophobic interactions,when a substantial amount of ethanol is mixed into water,the attraction between hydrophobic self-assembled monolayers becomes signi?cantly weakened[50].Even though no explicit data were given con-cerning adhesion hysteresis,the simultaneous signi?cant reduc-tion in both jump-in distance and pull-off force should indicate reduced adhesion hysteresis.In the case of a hydrophobic mono-layer interacting with a hydrophilic monolayer[51],both the pull-off distance and the pull-off force reduces signi?cantly with increasing amount of ethanol in the mixture of water and ethanol. From such similarity in phenomenology,it becomes appar-ent that in addition to bulk hysteretic loss in rubber,interfacial interactions across the sliding interface can also be a signi?-cant contributor to wet friction on a rough road surface.The different extent of reduction in BPN under ethanol lubrication exhibited by different compounds may re?ect the difference in relative proportion of the two friction contributors for each compound. Prior to each testing of wet friction under Conditions A and B, a brush bearing stainless steel hair was employed to refresh the concrete surface in the presence of suf?cient amount of liquid. The brush hair does wear away and some of the stainless steel wear particles do deposit onto the concrete surface.It is reason-able to be concerned on the potential in?uence of such stainless steel wear particles on the interfacial interactions between a rub-ber slider and the concrete surface.To address such concern, sliders of SBR-C and SBR-SiO2-Si69were tested under water lubrication on a fresh concrete surface without any prior his-tory of being brushed.Under Condition A,in the absence of brushing,BPN exhibited more variation with time,especially at the beginning.However,the difference in BPN between SBR-C and SBR-SiO2-Si69persists.On the other hand,refreshing the surface via brushing does lead to a much stabilized BPN reading. Practitioners have attempted to separate adhesion and hys-teretic contributions to sliding friction of elastomers[52,53]. This study may suggest that adhesion is substantially reduced under ethanol lubrication.For many people working in the rub-ber industry,adhesive friction(under dry conditions)is strongly associated with the image of breakup and reformation of bonds across the interface[54,55].On the other hand,it is obvious from modern studies on intermolecular interactions that even separated with tens layers of water molecules,under proper con-ditions,signi?cant attractive interactions are present[40].Thus direct contact is probably not a prerequisite for the relevance of adhesion to wet friction. The diameter of water molecules is about2.5?A[40].The thickness of20layers of water molecules is about5nm.The typical primary particle size for?ller is above10nm while an individual?ller particle consists of tens of primary particles fused together.It is thus clear that for consideration of interfacial interactions between?ller particles and the road surface across a molecularly thin layer of water,the continuum viscoelastic description of bulk material behavior is not of direct relevance. On the other hand,it has been pointed out not long ago that poly-mer viscoelasticity is not the prerequisite for the appearance of the bell-shaped variation of friction with temperature or slid-ing speed[56].It has been detected from microscopic friction characterization for non-polymeric systems. Considering that both the original silica particles and the Port-land cement concrete surface are hydrophilic,the enhanced wet traction from silica does not necessarily come from hydropho-bic interactions.However,if the phenomenon of strong attractive hydrophobic interactions in water,with improved mechanistic understanding[57,58],can be appropriately controlled,it may be a factor to consider for enhancing wet traction.In water the exis-tence of an extremely thin layer of gas phase at a hydrophobic surface has been discussed[59,60].It is unclear how interfa-cial interactions between the hydrophobic rubber surface and the hydrophilic concrete surface in relative motion are affected by the state of water con?ned in-between. Putting into consideration the complete set of phenomenol-ogy and contemplating from the right perspective,it is possible to achieve a coherent understanding on friction mechanisms suf-?cient for rational material design.This shall open the door for further enhancing tire wet traction performance and more impor-tantly the safety of the driving public. 4.Summary Wet sliding friction of various elastomer compounds on a rough Portland cement concrete surface is examined under different lubrication conditions.The lubrication condition is adjusted via varying the initial amount of liquid–ethanol or water present on the surface.While the surface remains visually wet under all testing conditions examined,wet sliding friction is detected to vary with the lubrication condition.Overall wet friction becomes markedly reduced under ethanol lubrication in comparison to that under water lubrication.This is accompanied with a less severe wear scar at the tested edge of rubber sliders under ethanol lubrication.In comparison to a carbon black-?lled compound,silica-reinforced compounds exhibit higher wet sliding friction in water.However,such effect from silica is eliminated in ethanol.These observations resemble features of interfacial interactions revealed from investigations employing AFM(in the absence of sliding),hence strongly indicate that in addition to bulk viscoelastic hysteresis,interfacial interactions between?ller particles and the road surface are also a signi?cant contributor to wet sliding friction of elastomer compounds on a rough surface.Contribution to wet friction from such interfacial interactions may exhibit temperature dependency different from that corresponding to the contribution from bulk viscoelastic-ity.The potential relevance of capillary porosity in concrete and Marangoni drying effect to wet traction is also introduced.More quantitative studies will undoubtedly result in our improved capability of rational material design for further enhanced public driving safety. Acknowledgements The permission of Bridgestone/Firestone North American Tire,LLC to publish this work is much appreciated.I thank M.W. Hayes for DSC and GPC tests;D.R.Brumbaugh for NMR test; 716X.-D.Pan/Wear262(2007)707–717 J.Anson for tensile test;J.N.Israelachvili,J.Klein and H.A. Stone for literature. References [1]S.Wolff,U.G¨o rl,M.-J.Wang,W.Wolff,Silica-based tread compounds, Eur.Rubber J.176(1994)16–19. [2]A.Schallamach,K.Grosch,Tire traction and wear,in:S.K.Clark(Ed.), Mechanics of Pneumatic Tires,U.S.Department of Transportation,Wash-ington,DC,1981,pp.365–474. [3]A.D.Roberts,A guide to estimating the friction of rubber,Rubber Chem. Technol.65(1992)673–686. [4]K.A.Grosch,The rolling resistance,wear and traction properties of tread compounds,Rubber Chem.Technol.69(1996)495–568. [5]K.A.Grosch,Relation between the friction and visco-elastic properties of rubber,Nature197(1963)858–859. [6]J.D.Ferry,Viscoelastic Properties of Polymers,third ed.,John Wiley& Sons,New York,1980. [7]T.French,R.G.Patton,Advances in roadholding characteristics of car tyres,in:T.H.Messenger(Ed.),Proceedings of the Fourth Rubber Tech-nology Conference,Institution of the Rubber Industry,London,1963, pp.196–216. [8]E.P.Percarpio,E.M.Bevilacqua,Lubricated friction of https://www.sodocs.net/doc/031627142.html,- ponents of friction in mating surfaces,Rubber Chem.Technol.41(1968) 854–861. [9]A.D.Roberts,A.G.Thomas,The adhesion and friction of smooth rubber surfaces,Wear33(1975)45–64. [10]K.Kendall,Rolling friction and adhesion between smooth solids,Wear33 (1975)351–358. [11]H.Yoshizawa,Y.-L.Chen,J.N.Israelachvili,Fundamental mechanisms of interfacial friction.I.Relation between adhesion and friction,J.Phys. Chem.97(1993)4128–4140. [12]J.A.Greenwood,D.Tabor,The friction of hard sliders on lubricated rubber: the importance of deformation losses,Proc.Phys.Soc.(Lond.)71(1958) 989–1001. [13]A.D.Roberts,in:D.F.Hays,A.L.Browne(Eds.),The Physics of Tire Traction,Plenum,New York,1974,p.214. [14]S.C.Richards,A.D.Roberts,Lubrication of rubber by aqueous and non- aqueous liquids,J.Nat.Rubber Res.3(1988)210–222. [15]A.D.Roberts,D.Tabor,The extrusion of liquids between highly elastic solids,Proc.R.Soc.Lond.A325(1971)323–345. [16]A.D.Roberts,Rubber friction:‘wet’Schallamach waves,J.Nat.Rubber Res.4(1989)166–178. [17]F.Brochard-Wyart,P.-G.de Gennes,Dewetting of a water?lm between a solid and a rubber,J.Phys.Condens.Mater.6(1994)A9–A12. [18]A.Martin,A.Buguin,F.Brochard-Wyart,Dewetting nucleation centers at soft interfaces,Langmuir17(2001)6553–6559. [19]A.Martin,J.Clain,A.Buguin,F.Brochard-Wyart,Wetting transitions at soft,sliding interfaces,Phys.Rev.E65(2002)031605. [20]G.Carbone,B.N.J.Persson,Dewetting at soft viscoelastic interfaces,J. Chem.Phys.121(2004)2246–2252. [21]C.P.Vernet,Ultra-durable concretes:structure at the micro-and nanoscale, MRS Bull.29(2004)324–327. [22]J.W.Hutchinson,T.Y.Kao,L.C.Pendley,Pavement dynamic permeability testing,in:Highway Skid Resistance,Special Technical Publication No. 456,American Society for Testing and Materials,Philadelphia,1969,pp. 159–176. [23]S.P.Arnold,A.D.Roberts,A.D.Taylor,Rubber friction dependence on roughness and surface energy,J.Nat.Rubber Res.2(1987)1–14. [24]B.N.J.Persson,U.Tartaglino,O.Albohr,E.Tosatti,Sealing is at the origin of rubber slipping on wet roads,Nat.Mater.3(2004)882–885. [25]A.Le Gal,X.Yang,M.Kl¨u ppel,Evaluation of sliding friction and contact mechanics of elastomers based on dynamic–mechanical analysis,J.Chem. Phys.123(2005)014704. [26]D.M.Dryden,J.R.Luchini,G.B.Ouyang,Trends in tyre technology,in: S.K.De,J.R.White(Eds.),Rubber Technologist’s Handbook,Rapra Tech-nology,Shawbury,2001,pp.351–400.[27]T.Fujimaki,K.Morita,Recent patents on silica reinforced polymers,Int. Polym.Sci.Technol.26(1999)26–34. [28]C.G.Giles,B.E.Sabey,K.H.F.Cardew,Development and performance of the portable skid resistance tester,in:Symposium on Skid Resistance, Special Technical Publication No.326,American Society for Testing and Materials,Philadelphia,1962,pp.50–74. [29]E.M.Bevilacqua,E.P.Percarpio,Friction of rubber on wet surfaces,Science 160(1968)959–964. [30]B.E.Sabey,G.N.Lupton,Friction on wet surfaces of tire-tread-type vul- canizates,Rubber Chem.Technol.37(1964)878–893. [31]S.Kawakami,M.Misawa,H.Hirakawa,The relation between temperature dependence of viscoelasticity and friction due to hysteresis,Rubber World 198(1988)30–38. [32]X.-D.Pan,Relationship between the dynamic softening transition and wet sliding friction of elastomer compounds,J.Polym.Sci.,Part B:Polym. Phys.42(2004)2467–2478. [33]X.-D.Pan,Impact of reinforcing?ller on the dynamic moduli of elastomer compounds under shear deformation in relation to wet sliding friction, Rheol.Acta44(2005)379–395. [34]X.-D.Pan,Signi?cance of tuning bulk viscoelasticity via polymer molec- ular design on wet sliding friction of elastomer compounds,Tribol.Lett. 20(2005)209–219. [35]C.G.Giles,B.E.Sabey,The effect of pressure and friction on photographic emulsions,Br.J.Appl.Phys.2(1951)174. [36]Y.Zhu,S.Granick,Viscosity of interfacial water,Phys.Rev.Lett.87(2001) 096104. [37]J.N.Israelachvili,P.M.McGuiggan,A.M.Homola,Dynamic properties of molecularly thin liquid?lms,Science240(1988)189–191. [38]S.Granick,Motions and relaxations of con?ned liquids,Science253(1991) 1374–1379. [39]J.Klein,E.Kumacheva,Con?nement-induced phase transitions in simple liquids,Science269(1995)816–819. [40]J.N.Israelachvili, A.D.Berman,Surface forces and microrheology of molecularly thin liquid?lms,in:B.Bhushan(Ed.),Handbook of Micro/Nano Tribology,second ed.,CRC Press,Boca Raton,1999,pp. 371–432. [41]U.Raviv,https://www.sodocs.net/doc/031627142.html,urat,J.Klein,Fluidity of water con?ned to subnanometer ?lms,Nature413(2001)51–54. [42]K.Nanjundiah,A.Dhinojwala,Con?nement-induced ordering of alka- nes between an elastomer and a solid surface,Phys.Rev.Lett.95(2005) 154301. [43]D.R.Lide,CRC Handbook of Chemistry and Physics,79th ed.,CRC Press, Boca Raton,1998. [44]A.B.Afsar-Siddiqui,P.F.Luckham,O.K.Matar,The spreading of surfac- tant solutions on thin liquid?lms,Adv.Colloid Interface Sci.106(2003) 183–236. [45]A.F.M.Leenaars,J.A.M.Huethorst,J.J.van Oekel,Marangoni dry- ing:a new extremely clean drying process,Langmuir6(1990) 1701–1703. [46]E.L.Ong,A.D.Roberts,Experiments on the lubrication of raw natural rubber,J.Nat.Rubber Res.1(1986)41–50. [47]A.Browne,K.C.Ludema,S.K.Clark,Contact between the tire and road- way,in:S.K.Clark(Ed.),Mechanics of Pneumatic Tires,U.S.Department of Transportation,Washington,DC,1981,pp.315–317. [48]B.N.J.Persson,U.Tartaglino,E.Tosatti,O.Albohr,Rubber friction on wet rough substrates at low sliding velocity:the sealing effect,Kautsch Gummi Kunstst57(2004)532–537. [49]J.Timmermans,Physico-Chemical Constants of Pure Organic Compounds, Elsevier,Amsterdam,1950. [50]E.Kokkoli,C.F.Zukoski,Effect of solvents on interactions between hydrophobic self-assembled monolayers,J.Colloid Interface Sci.209 (1999)60–65. [51]G.Papastavrou,S.Akari,H.M¨o hwald,Interactions between hydrophilic and hydrophobic surfaces on microscopic scale and the in?uence of air bubbles as observed by scanning force microscopy in aqueous and alcoholic mediums,Europhys.Lett.52(2000)551–556. [52]J.D.Carter,Re-evaluation of orientation effects in the friction of a hard ellipsoid sliding on rubber,J.Appl.Phys.93(2003)1283–1286. X.-D.Pan/Wear262(2007)707–717717 [53]N.Amino,Y.Uchiyama,T.Iwai,M.Maeda,Studies of friction mechanism in silica and carbon black?lled SBR:(3)friction of carbon black and silica ?lled SBR blends,Int.Polym.Sci.Technol.30(2003)13–20. [54]A.Schallamach,A theory of dynamic rubber friction,Wear6(1963) 375–382. [55]Y.B.Chernyak,A.I.Leonov,On the theory of the adhesive friction of elas- tomers,Wear108(1986)105–138. [56]G.Luengo,J.N.Israelachvili,S.Granick,Generalized effects in con- ?ned?uids:new friction map for boundary lubrication,Wear200(1996) 328–335.[57]E.E.Meyer,Q.Lin,T.Hassenkam,E.Oroudjev,J.Israelachvili,Origin of the long-range attraction between surfactant-coated surfaces,Proc.Natl. Acad.Sci.U.S.A.102(2005)6839–6842. [58]E.E.Meyer,K.J.Rosenberg,J.Israelachvili,Recent progress in under- standing hydrophobic interactions,Proc.Natl.Acad.Sci.U.S.A.,in press (2006). [59]X.-Y.Zhang,Y.-X.Zhu,S.Granick,Hydrophobicity at a Janus interface, Science295(2002)663–666. [60]S.Granick,Y.-X.Zhu,H.-J.Lee,Slippery questions about complex?uids ?owing past solids,Nat.Mater.2(2003)221–227. 热轧工艺流程 热轧工艺流程----初学必看 1.主轧线工艺流程简述 板坯由炼钢连铸车间的连铸机出坯辊道直接送到热轧车间板坯库,直接热装的钢坯送至加热炉的装炉辊道装炉加热,不能直接热装的钢坯由吊车吊入保温坑,保温后由吊车吊运至上料台架,然后经加热炉装炉辊道装炉加热,并留有直接轧制的可能。 连铸板坯由连铸车间通过板坯上料辊道或板坯卸料辊道运入板坯库,当板坯到达入口点前,有关该板坯的技术数据已由连铸车间的计算机系统送到了热轧厂的计算机系统,并在监视器上显示板坯有关数据,以便工作人员进行无缺陷合格板坯的核对和接收。另外,通过过跨台车运来的人工检查清理后的板坯也需核对和验收,并输入计算机。进入板坯库的板坯,由板坯库计算机管理系统根据轧制计划确定其流向。 常规板坯装炉轧制:板坯进入板坯库后,按照板坯库控制系统的统一指令,由板坯夹钳吊车将板坯堆放到板坯库中指定的垛位。轧制时,根据轧制计划,由板坯夹钳吊车逐块将板坯从垛位上吊出,吊到板坯上料台架上上料,板坯经称量辊道称重、核对,然后送往加热炉装炉辊道,板坯经测长、定位后,由装钢机装入加热炉进行加热。 碳钢保温坑热装轧制:板坯进入板坯库后,按照板坯库控制系统的统一指令,由板坯夹钳吊车将板坯堆放到保温坑中指定的垛位。轧制时,根据轧制计划,由板坯夹钳吊车逐块将板坯从保温坑取出,吊到板坯上料台架上上料,板坯经称量辊道称重、核对,然后送往加热炉装炉辊道,板坯经测长、定位后,由装钢机装入加热炉进行加热。 直接热装轧制:当连铸和热轧的生产计划相匹配时,合格的高温连铸板坯通过加热炉上料辊道运到称量辊道,经称重、核对,进入加热炉的装炉辊道,板坯在指定的加热炉前测长、定位后,由装钢机装入加热炉进行加热。其中一部分通过卸料辊道运输的直接热装板坯需通过吊车吊运一次放到上料辊道后直接送至加热炉区。如果炼钢厂可以实现直接热装板坯由上料辊道运送,则可减少部分吊车吊运作业。 板坯经加热炉的上料辊道送到加热炉后由托入机装到加热炉内,加热到设定温度后,按轧制节奏要求由出钢机托出,放在加热炉出炉辊道上。 加热好的板坯出炉后通过输送辊道输送,经过高压水除鳞装置除鳞后,将板坯送入定宽压力机根据需要进行侧压定宽。定宽压力机一次最大减宽量为350 mm。然后由辊道运送进入第一架二辊可逆粗轧机轧制及第二架四辊可逆粗轧机进轧制,根据工艺要求将板坯轧制成厚度约为30-60mm的中间坯。在各粗轧机前的立辊轧机可对中间坯的宽度进行控制。 水工艺设备基础 一、填空题(每空1分,共20分) 1、在水处理工艺中,搅拌器的形式多种多样,应根据工艺要求来选用,常用的搅拌器有:浆式搅拌器、推进式搅拌器、涡轮搅拌器等。 2、Ni-Mo合金是耐盐酸腐蚀的优异材料。最有名的哈氏合金(0Cr16Ni57Mo16Fe6W4)能耐室温下所有浓度的盐酸和氢氟酸。 3、热量传递有三种基本方式:热传导、热对流和热辐射。 4、改变介质的腐蚀特性一般有两种途径:一种是去除介质中有害成分;另一种是加缓蚀剂。 5、从使用角度看,法兰连接可分为两大类,即压力容器法兰和管法兰。 6、按换热设备的换热方式可分为直接式、蓄热式和间壁式换热设备 7、水处理工艺中,最常用的三种膜分离设备为电渗析设备、反渗透设备和超滤设备。 8、吸泥机排泥方式有虹吸、泵吸和空气提升。 二、单选题(每题1分,共10分) 1、陶瓷最大的缺点是( A )。 A.脆性 B.易腐蚀 C.韧性差 D.熔点低 2、水处理工艺设备发生的腐蚀多属于( B )。 A.局部腐蚀 B.全面腐蚀 C.应力腐蚀 D.微生物腐蚀 3、渗透压与溶液的,和有关,而与无关。( B ) A.膜、浓度、温度、溶液性质 B.浓度、温度、溶液性质、膜 C.温度、膜、浓度、溶液性质 D.溶液性质、浓度、膜、温度 4、法兰连接的失效主要表现为( A )。 A.发生泄漏 B.出现缝隙 C.螺栓松动 D.以上皆是 5搅拌式设备有多种形式,哪个不是按功能分的( A )。 A.水利搅拌设备 B.混合搅拌设备 C.搅动设备 D.分散搅拌设备 6、传统的容积式换热器的优点不包括( D )。 A.兼具换热、贮热功能 B.阻力损失小 C.结构简单、管理方便 D.节能 7、曝气的主要作用有( D )。 A.充氧 B.搅拌 C.混合 D.以上都是 8、下列气浮分离设备应用做广泛的是( B )。 A.微孔布气气浮设备 B.压力溶气气浮设备 C.电解气浮设备 D.射流气浮设备 9、下列不是排泥设备种类的是( C )。 A.行车式 B.螺旋输送式 C.平板式 D.中心传动式 10、下列设备不属于计量设备的是( D )。 A.转子流量计 B.电磁流量计 C.超声流量计 D.电动流量计 三、多选题(每题2分,共20分) 1、高分子材料主要包括哪几种?( ACD ) A.树脂 B.塑料 C.合成纤维 D 合成橡胶 2、发生应力腐蚀的三个必要条件( BCD )。 A.一定空气湿度 B.敏感的合金 C.特定的介质 D.一定的静应力 3、卧式容器的支座主要有、和三种。( BCD ) A.耳式支座 B.鞍座 C.圈座 D.支承式支座 4、水工艺中常用的机械搅拌设备主要有哪几种?( ABD ) A.溶液搅拌设备 B.混合搅拌设备 C.分散搅拌设备 D.絮凝搅拌设备。 5、水处理中常用的曝气设备有( ABCDE ) A.表面曝气设备 B.鼓风曝气 C.水下曝气 D.纯氧曝气 E.深井曝气 6、换热器的选型需综合考虑的因素有( ABCE ) 热轧工艺流程 热轧工艺流程——--初学必看1.主轧线工艺流程简述板坯由炼钢连铸车间的连铸机出坯辊道直接送到热轧车间板坯库,直接热装的钢坯送至加热炉的装炉辊道装炉加热,不能直接热装的钢坯由吊车吊入保温坑,保温后由吊车吊运至上料台架,然后经加热炉装炉辊道装炉加热,并留有直接轧制的可能。连铸板坯由连铸车间通过板坯上料辊道或板坯卸料辊道运入板坯库,当板坯到达入口点前,有关该板坯的技术数据已由连铸车间的计算机系统送到了热轧厂的计算机系统,并在监视器上显示板坯有关数据,以便工作人员进行无缺陷合格板坯的核对和接收。另外,通过过跨台车运来的人工检查清理后的板坯也需核对和验收,并输入计算机.进入板坯库的板坯,由板坯库计算机管理系统根据轧制计划确定其流向。 常规板坯装炉轧制:板坯进入板坯库后,按照板坯库控制系统的统一指令,由板坯夹钳吊车将板坯堆放到板坯库中指定的垛位。轧制时,根据轧制计划,由板坯夹钳吊车逐块将板坯从垛位上吊出,吊到板坯上料台架上上料,板坯经称量辊道称重、核对,然后送往加热炉装炉辊道,板坯经测长、定位后,由装钢机装入加热炉进行加热。碳钢保温坑热装轧制:板坯进入板坯库后,按照板坯库控制系统的统一指令,由板坯夹钳吊车将板坯堆放到保温坑中指定的垛位。轧制时,根据轧制计划,由板坯夹钳吊车逐块将板坯从保温坑取出,吊到板坯上料台架上上料,板坯经称量辊道称重、核对,然后送往加热炉装炉辊道,板坯经测长、定位后,由装钢机装入加热炉进行加热。直接热装轧制:当连铸和热轧的生产计划相匹配时,合格的高温连铸板坯通过加热炉上料辊道运到称量辊道,经称重、核对,进入加热炉的装炉辊道,板坯在指定的加热炉前测长、定位后,由装钢机装入加热炉进行加热。其中一部分通过卸料辊道运输的直接热装板坯需通过吊车吊运一次放到上料辊道后直接送至加热炉区。如果炼钢厂可以实现直接热装板坯由上料辊道运送,则可减少部分吊车吊运作业。 南通宝钢热轧产线工艺设备 基本情况 1 总体情况说明 1.1 生产规模 热轧产线为生产规模年产50万t低合金钢棒材,考虑控制冷却技术及小规格切分轧制技术。φ10为三切分工艺,φ12、φ14为两切分工艺,φ16为两切分和单线两种工艺,其余规格为单线轧制工艺。 1.2产品方案 序号品种钢种代表规格年产量比例钢号(mm)(万吨) (%) 1 螺纹钢低合金钢 HRB335、 HRB335E、 HRB400、 HRB400E、 HRB500、 HRB500E φ10~φ14 11.25 22.5 2 φ16~φ18 12 24 3 φ20~φ25 19.5 39 4 φ28~φ36 5 10 5 φ40 2.25 4.5 合计50 100.00 注:连铸坯规格为:150mm×150mm×8000mm,加热炉能力要 求不低于100t/h。 1.3生产工艺流程 1.3.1 车间生产工艺流程框图 连铸 吊运至上料台 辊道输送 推钢入炉 加热 出炉 (不合格坯剔除) 粗轧 切头 中轧 控制冷却 切头 倍尺分段 冷床冷却 冷剪剪切定尺 移送、检查、计数 打捆 称重标志 收集 入库 精轧 1.3.2 生产工艺过程简述 合格的连铸钢坯由炼钢连铸车间用电动平车运输至本车间,然后用吊车吊运至上料台架,坯料由上料台架推入坯料输送辊道,并输送到加热炉入炉端后由推钢机将其从加热炉的端部推到推钢式加热炉中加热。 根据钢种的要求,钢坯在加热炉内加热到1030~1130℃后,按轧制节奏由出钢机从加热炉侧面单根推出炉。如果钢坯有缺陷,由剔除装置从出炉辊道上剔除。 出炉后的热坯,经辊道输送,钢坯开始进入连轧机组轧制。钢坯首先在粗轧机组轧制6个道次,然后轧件由1#飞剪切头后,进入中轧机组轧制,轧成工艺规程要求的断面。 出中轧机组的轧件,再由2#飞剪切去头尾,继续进入精轧机组轧成最终要求的成品断面尺寸。 当轧制过程出现事故时,1#、2#飞剪手动启动,进行连续剪切,将轧件碎断,防止事故进一步扩大。 φ10~φ40mm低合金钢在轧制后立即进入水冷装置进行余热淬火回火处理。 在水冷装置之后设有分段飞剪用来将轧件切成冷床长度(成品倍尺),倍尺飞剪采用优化剪切,随后倍尺轧件沿冷床输入辊道输送,并由升降裙板制动后进入冷床冷却。轧件齐头后由链式移送机按一定间距和数量形成棒材层,然后由托出小车成层移入冷床输出辊道。 水工艺设备基础考试复 习要点 内部编号:(YUUT-TBBY-MMUT-URRUY-UOOY-DBUYI-0128) 《水工艺设备基础》复习要点一考 试类型及题型 1)闭卷; 2)单项选择题;填空题;简答题;计算题;论述题(分值有变化,单选和填空分值有所减少) 二知识点 第一章.水工艺设备常用材料 1)掌握水工艺设备常用材料有哪些 2)了解钢的分类,如按用途分为:结构钢、工具钢和特殊性能钢。 ①按化学成份分类:碳钢和合金钢;A.碳钢按含碳量又可分为:低碳 钢、中碳钢和高碳钢;B.合金钢按含合金元素的含量又可分为:低合金钢、中合金钢和高合金钢;②按照钢中硫和磷的含量又可分为:普通钢、优质钢、高级优质钢;③根据钢的用途又可分为:结构钢、工具钢和特殊性能钢 3)掌握钢的编号的意义:如合金工具钢9SiCr 钢(%);碳素工具钢T8表示什么含义(%) 第二章. 材料设备的腐蚀﹑防护与保温 1. 材料设备的腐蚀与防护 1)了解什么叫腐蚀及其危害 2)掌握设备防蚀技术中关于防蚀结构设计需要遵循的基本原则 3)掌握:a.什么是应力腐蚀及其发生的条件 b.设备防蚀技术中关于改变介质腐蚀特性的途径是什么 4)重点掌握:a.微生物腐蚀产生的原因及其最常见的微生物腐蚀类型;b.水处理工艺设备常用材料的选择原则(可能出简答题) 2. 设备的保温 了解设备保温的目的 第三章水工艺设备理论基础 1. 容器应力理论 1)掌握什么是薄壁容器判断标准 2)了解容器设计的基本要求 1)工艺要求:容器的总体尺寸、接口管的数目与位置、介质的工作压力、填料种类、规格、厚度等一般都要根据工艺生产的要求通过工艺设计计算及生产经验决定。2)机械设计的要求:(1)容器要有足够的强度(2)要有足够的刚度(3)要具有足够的稳定(4)容器必须有足够的严密性(5)抗腐蚀性和抗冲刷性要好(6)在保证工艺要求、和机械设计要求的基础上,应选择较为便宜的材料,以降低制作成本。(7)确保制作、安转、运输及维护方便。 3)重点掌握圆柱壳薄壁容器的应力计算方法(记公式、弄懂每个参数的意义,会用)会出个计算题(课本 P98页) 1 热轧轧制基本原理及基本工艺 一.概论 铝是目前仅次于钢铁的第二类金属,其板带材具有质轻、比强度高、耐蚀、可焊、易加工、表面美观等特点被广泛的应用于国民经济的各个行业,特别是航空航天、包装印刷、建筑装饰、电子家电、交通运输等领域。比如,航空航天方面,前几天发射的“神八”飞船,上面好多铝及铝合金用品都是西南铝和东轻公司加工制造的,不过这些产品一般都是军工产品,我们目前还没有生产的权利,我们厂也没有参与加工,但是也是铝加工行业的骄傲。 包装印刷方面,大家都熟知的PS版,虽然现在我们已经退出了这个产品的生产竞争行列,但是我们曾经生产过,曾经取得过比较好的生产成绩。建筑装饰方面,我们生产过的主要有铝塑底板带,大批量的各系合金的氧化带等。 电子家电方面较多,前段时间大批量生产的液晶电视背板,键盘料等。交通运输方面,大家熟知的5754声屏障。虽然有些产品我们已经不再生产,但是这些产品我们不再陌生,到超市里面逛街的时候看看电饭煲盖子里的铝板,看看各种大型的液晶电视,可能某些产品所用的铝及铝合金配件就是我们厂生产的呢! 二.热轧的简单概念及特点 热轧是指在金属再结晶温度以上进行的轧制。 再结晶就是当退火温度足够高,时间足够长时,在变形金属或合金的纤维组织中产生无应变的新晶粒(再结晶核心),新晶粒不断的长大,直至原来的变形组织完全消失,金属或合金的性能也发生显著变化,这一过程称为再结晶,其中开始生成新晶粒的温度称为开始再结晶温度,显微组织全部被新晶粒所占据的温度称为终了再结晶温度,一般我们所称的再结晶温度就是开始再结晶温度和终了再结晶温度的算术平均值,一般再结晶温度主要受合金成分、形变程度、原始晶粒度、退火温度等因素的影响 以上就是理论上的热轧的简单原理,在我们铝加工行业的实际生产中主要的体现是,当铸锭在加热炉内加热到一定的温度,也就是再结晶温度以上时,进行的轧制,而这一个温度的确定主要依据是铝合金的相图,也就是最理想化的情况下,加热温度的确定为该合金在多元相图中固相线80%处的温度为依据,这就牵扯到了不同合金多元相图的问题,比较深奥,所以我们只要知道,加热温度的确定是以该合金固相线的80%为依据,在制度的执行中,根据实际的生产情况,根据设备的运行情况,多加修改所得到的适合该合金生产的温度 热轧的特点: 1、能耗低,塑性加工良好,变形抗力低,加工硬化不明显,易进 行轧制,减少了金属变形所需的能耗 2、热轧通常采用大铸锭、大压下量轧制,生产节奏快,产量大, 这样为规模化大生产创造了条件 3、通过热轧将铸态组织转变为加工组织,通过组织的转变使材料 的塑性大幅度的提高 4、轧制方式的特性决定了轧后板材性能存在着各向异性,一是材 1、水工艺设备常用的金属材料主要有碳钢、铸铁、合金钢、不锈钢以及部分有色金属材料等。 2、按照钢中硫和磷的含量可分为普通钢、优质钢和高级优质钢。普通钢 S<=0.055%,P<=0.045%;优质钢S、P均应<=0.040%;高级优质钢S<=0.030%,P<=0.035%。 3、根据钢的用途可分为结构钢、工具钢、特殊性能钢。 4、Q275表示屈服强度为275MPa的碳素结构钢。 5、含碳0.45%(万分之四十五)左右的优质碳素结构钢编号为45钢。 6、碳素工具钢的含碳量一般介于0.65%~1.35%之间。 7、30CrMnSi钢,其平均含碳量为0.3%,铬、锰、硅三种合金元素的含量均小于1.5% 8、金属材料的基本性能是指它的物理性能、机械性能、化学性能、和工艺性能。 9、化学成分的变化对钢材的基本力学性能如强度及塑韧性等有较大的影响。 10、屈服极限是金属材料开始产生屈服现象时的应力,以σs表示,单位为MPa。对于没有明显屈服点的材料,规定以产生0.2%塑性变形时的应力作为屈服强度,表示。 以σ 0.2 11、疲劳强度是指材料在经受N次应力循环而不断裂时的最大应力,以σ-1(纯 (扭转疲劳)表示,单位为MPa。N为102~105次发生破坏的为低弯曲疲劳)τ -1 循环疲劳破坏,多发生在容器构件上,N超过105次的为高循环疲劳破坏,多用于一般机械零件,钢铁材料N为107,有色金属和某些超高强度钢N为108。12、材料在加工方面的物理、化学和机械性能的综合表现构成了材料的工艺性能,又叫加工性能。 13、水工艺设备主要零部件的制造工艺过程主要是焊接、锻造、切削、冲压、弯曲和热处理 14、在铸铁中加入某些合金元素可以大大提高它在一些介质中的耐蚀性。如硅、铬、铝,可使铸铁表面形成连续、致密、牢固的表面膜;镍能获得耐碱性介质腐蚀性能优良的奥氏体铸铁;稀土元素、镁,能使石墨球化,从而大大改善高硅铸铁的力学性能和工艺性能 15、耐蚀低合金钢通常是指在碳钢中加入合金元素的总量低于3%左右的合金。加入少量的铜、铬、铝等元素能使钢表面形成稳定的保护膜,从而提高钢在海水、大气等介质中的耐蚀性。 16、耐蚀低合金钢有:耐大气腐蚀钢种:铜系列有16MnCu、09MnCuPTi、 15MnVCu、10PCuRe等;磷钒系列有10MnPV等,磷稀土系列有08MnPRe、12MnPRe等;磷铌稀土系列有10MnPNbRe等;耐海水腐蚀钢种:10CrMoAl、09CuWSn、08PV、10MnPNbRe等;耐硫化氢腐蚀钢种:12AlV、12MoAlV、15Al3MoWTi、12Cr2MoAlV、40B。 17、不锈钢是铬、镍含量较高的合金钢。 18、不锈钢按显微组织可分为马氏不锈钢、铁素体不锈钢和奥氏体不锈钢。 19、不锈钢按化学成分可分为铬不锈钢和铬镍不锈钢。 20、奥氏体不锈钢可用于制作在腐蚀性介质中使用的设备。 21、工业上钢铁称为黑色金属。除钢铁以外的金属称为有色金属 22、在水处理工程、化工机械与设备制造中应用较多的有色金属,主要有铜、铝、钛、铅、镍及其合金 23、黄铜:铜与锌组成的合金称为黄铜。 1780热轧生产工艺与设备 6.1 1780热轧的产品、规格及生产能力 宝钢股份不锈钢分公司1780mm热轧以热轧不锈钢钢卷为主导产品,同时发挥轧机能力大、控制水平高的特点,兼顾生产薄规格、高强度、高附加值的优质碳素结构钢、低合金钢等。不锈钢包括200、300、400系列,其中奥氏体不锈钢约占总量的70%,铁素体不锈钢占25~27%,马氏体不锈钢占3~5%;碳素钢中包括双相、多相微合金钢,高强度钢及特殊用途钢等品种,且碳钢产品中以薄规格为主,厚度1.2~3.5mm约占80%,以生产热轧酸洗、热轧镀锌及以热代冷用钢卷。 一期的设计产量为年产热轧钢卷282.2万吨,其中不锈钢69.8万吨,碳钢212.4万吨。由于二期项目中炼钢扩建了炼钢和连铸生产线,热轧增加了3号加热炉,从而增加了近70万吨的不锈钢生产能力。 成品规格如下表所示: 代表钢种 成品厚度 (mm) 成品宽度(mm) 碳钢 低合金 钢 SPHC,SPHD,SPHE,10P CuRE, SPA-H,SM400A -C SM490A - C,15MnV,09MnNb 1.2~1 2.75 750~1630 不锈钢 304,304L,316,316L, 410,420,409,430 2.0~10.0 750~1600 6.2 1780热轧的生产设备及工艺流程 6.2.1热轧生产线的主要工艺设备: 1 10 3 4 5 6 7 8 9 11 12 3 2 1 2 1-三座加热炉;2-高压水除鳞箱(HSB );3-粗轧除鳞;4-粗轧前大立辊(VE );5-粗轧机(RM );6-热卷箱(CB );7-飞剪(CS );8-精轧前除鳞装置;9-精轧前立辊(F1E );10-7机架的精轧机;11-层流冷却;12-两台地下卷取机(DC )。 6.2.2 生产工艺流程 板坯加热 高压水除鳞 粗轧 飞剪 热卷箱 热卷箱炉 精轧前除鳞 精轧机 层流冷却 卷取 钢卷运输 入库 检查取样 打包、验收 发货 平整分卷 发货、打包、验收 第1章水工艺设备常用材料 1. 金属材料的基本性能包括哪几个方面的内容?你认为水工艺设备对金属材料的哪些性能要求更高?怎样才能满足这些要求? 答:使用性能:1 化学性能:抗氧化性和耐腐蚀性。2 物理性能:密度,熔点,热膨胀系数,导热性以及弹性模量等。3 机械性能:弹性,塑性,强度和韧性。工艺性能:可焊性,可锻性,切削加工性,成型工艺性,热处理性能。 我觉得水工艺设备对金属材料的强度,刚度和抗腐蚀性的性能要求更高。 按照实际的工程需要,通过不同材料间的比较,从中选出较优的材料。 2.钢的分类与编号如何? 答:分类:按化学成分分类:碳钢和合金钢。分别又分为低中高。 按质量分类:普通钢,优质钢,高级优质钢(硫磷的含量区分) 用途分类:结构钢,工具钢和特殊性能钢。 编号:(1)普通碳素结构钢:Q+数字表示。Q275表示屈服强度为275MPa的碳素结构钢。 (2)优质碳素结构钢:采用两位数字表示钢中平均含碳量为万分之几。含碳为0.45%的编号为45钢。 (3)碳素工具钢:以“T”开头,后面标以数字表示含碳量的千分之几。高级就在最后加以“A”。 (4)合金结构钢:两位数字+元素符号+数字来表示。两位数字表示含碳量的万分之几,元素符号表示所含的合金元素,数字表示该元素的百分之几。 (5)合金工具钢:和合金结构钢类似。含碳量大于或等于1%时不予标出,小于的话用千分之几表示。 3. 影响钢材性能的因素主要有哪些? 答:碳是决定钢材的主要元素,随含碳量增加,钢的强度和硬度将不断提高,而塑性和韧性则会随之下降。硫是一种有害元素,产生“热脆”现象。 磷也是一种有害元素,产生“冷脆”现象。锰是一种有益元素,作为脱氧剂和合金元素,减轻硫的有害作用,提高钢的强度和硬度。硅是一种有益元素,作为脱氧剂和合金元素,提高强度,硬度,弹性,降低塑性和韧性。氧,氮:未除尽的氧氮大部分以化合物形式存在,降低强度,冷弯性能和焊接性能。氧增加热脆,氮增加冷脆。钛,钒,铌:钢的强脱氧剂和合金元素,改善韧性,提高强度。4. 合金钢有哪些类型?何谓耐蚀低合金钢?耐大气腐蚀、海水腐蚀的低合金钢中各含哪些主要合金元素? 答:按合金元素分为低中高合金钢。按用途分为合金结构钢,合金工具钢和特殊性能钢。特殊性能刚又分为不锈钢和耐热钢。 耐蚀低合金钢:在碳钢中加入合金元素的总量低于3%左右的合金,根据合金种类和含量不同起到不同的耐蚀性能。 耐大气腐蚀:铜,铬,铝耐海水腐蚀:铜,铬,铝,镍。 5. 不锈钢有哪些类型?在酸性介质、碱性介质及中性水溶液中是否可以选用同一种不锈钢?简述理由。 答:按显微组织为马氏体不锈钢,铁素体不锈钢和奥氏体不锈钢。按化学成分为铬不锈钢和铬镍不锈钢。不可以,因为不同介质溶液中PH值不同,对不锈钢的化学反应都不一样,所以不能用同一种不锈钢,应该有所针对的选择。 6. 铝、铜及其合金的主要性能特点是什么?主要用于什么场合? 答:铜及其合金具有高的导电性,导热性,塑性和冷韧性,并且在许多介质中具 第一章水工艺设备常用材料 1.水工艺设备常用的金属材料主要有:碳钢、铸铁、合金钢、不锈钢及部分有色金属材料等。 2.钢的分类:按化学成分分为碳钢和合金钢,按硫磷含量分为普通钢、优质钢、高级优质钢,按用途分为结构钢、工具钢、特殊性能钢。 3.钢的编号:Q+数字表示屈服强度值;标注A、B、C、D,表示钢材质量等级,A级最低,D级最高;标注F为沸腾钢,未标注为镇静钢:如q235—A·F,表示屈服强度为235MPa的A级沸腾钢。 4.合金结构钢编号:利用“两位数字+元素符号+数字”来表示,两位数字代表钢种平均含碳量的万分之几,元素符号表示钢中所含的合金元素,数字代表该元素的平均含量的百分之几,若平均含量低于1.5%,则不标明含量,若平均含量大于1.5%、2.5%、3.5%……,则相应地以2、3、4……表示。如12CrNi3钢,其平均含碳量为0.12%,平均含铬量小于1.5%,平均含镍量为3%。 5.合金工具钢:当其平均含碳量大于或等于1.00%时,含碳量不予标出,小于1.00%时,以千分之几表示,其余表示方法与合金结构钢相似,如9SiCr,其平均含碳量为0.9%,硅和铬的平均含量均小于1.5%。 6.金属的基本性能是指它的物理性能、机械性能、化学性能和工艺性能。 7.钢中的有益元素包括锰和硅,有害元素包括硫(热脆、断裂韧性降低)和磷(冷脆、但提高在大气中耐蚀性)。 8.材料的机械性能主要指材料的弹性、塑性、强度和韧性(冲击韧性、断裂韧性、无塑性转变温度)。 9.材料的工艺性能主要指材料的可焊性、可锻性、切削加工性、成型工艺性和热处理性能。 10.有色金属:工业上钢铁称为黑色金属,除钢铁以外的金属称为有色金属。 11.铜合金及其编号:铜与锌组成的合金称为黄铜,HSn70—1表示含铜70%,含锡1%的锡黄铜;铜合金中的主加元素不是锌而是锡、铝、硅等其他元素,称为青铜,QSn4—3,表示平均含锡量4%,含锌量3%的锡青铜。 12.无机非金属材料包括天然岩石、铸石、陶瓷、搪瓷、玻璃、水泥等。 13.陶瓷以黏土为主要原料,其刚度、硬度是各类材料中最高的,在室温下几乎没有塑性,具有很好的耐火性能和不可燃烧性,最大的缺点是脆性和热稳定性低,大多数陶瓷是良好的绝热体和绝缘体。 14.陶瓷和搪瓷的区别:搪瓷是金属和瓷釉的复合材料,兼有金属设备的力学性能和瓷釉的耐腐蚀性能。 15.高分子化合物的合成:加聚反应(无副产物)、缩聚反应(析出低分子物质)。 16.高分子材料性能:重量轻、高弹性、滞弹性、塑性和受迫弹性、强度(比金属低)与断裂(脆性断裂、韧性 断裂)、韧性(好)、减摩、耐磨性(好)、绝缘性(好)、耐热性(差)、耐蚀性(只化学腐蚀)、老化。 17.高分子材料主要包括合成树脂、合成橡胶和合成纤维三大类。 18.塑料的组成:塑料是指以有机合成树脂为主要组成材料,与其他配料混合,通过加热、加压塑造成一定形状的产品。塑料的性能主要取决于树脂,但在合成树脂中加入添加剂可对塑料进行改性。组成塑料的物质主要包括:合成树脂、填料(或增强材料)、固化剂、增塑剂、稳定剂、润滑剂、着色剂、阻燃剂。 19.塑料按受热性能分为热塑性塑料(加热时软化,可塑造成型,冷却后变硬,此过程可反复进行),热固性塑料(初加热时软化,可塑造成型,但固化后再加热,将不再软化,也不溶于溶剂)。 20.复合材料:为多相或多组成体系,全部相可分为两类,一类为基本相,主要起胶粘剂作用;另一类为增强相,起提高强度或韧性的作用。 21.复合材料性能特点:比强度和比刚度高、抗疲劳性能好、减振能力强、高温性能好、断裂安全性高。 第二章材料设备的腐蚀、防护与保温 1.腐蚀:是材料与它所处环境介质之间发生作用而引起材料的变质和破坏。 2.金属氧化的条件:金属氧化物的分解压低于0.022MPa,该金属就有可能在空气中氧化。 3.金属氧化膜起保护作用的条件: ①生成的金属膜必须致密、完整,能把金属表面全部遮盖住; ②金属氧化物本身是稳定、难溶和不挥发的,且不易于介质作用而被破坏; ③氧化膜与基体结合良好,有相近的热胀系数,不会自行或受外界作用而剥离脱落; ④氧化膜有足够的强度、塑性,足以经受一定的应力、应变的作用。 4.钢铁的气体腐蚀:钢铁在高温气体环境中很容易受到腐蚀,常见类型有:高温氧化、脱碳、氢蚀和铸铁肿胀;防止措施:合金化、改善介质、应用保护性覆盖层。 精品文档 第一章水工艺设备常用材料 1. 金属材料的基本性能包括哪几个方面的内容?你认为水工艺设备对金属材 料的哪些性能要求更高?怎样才能满足这些要求?答:使用性能:1 化学性能:抗氧化性和耐腐蚀性。2 物理性能:密度,熔点,热膨胀系数,导热性以及弹性模量等。3 机械性能:弹性,塑性,强度和韧性。工艺性能:可焊性,可锻性,切削加工性,成型工艺性,热处理性能。我觉得水工艺设备对金属材料的强度,刚度和抗腐蚀性的性能要求更高。按照实际的工程需要,通过不同材料间的比较,从中选出较优的材料。 2. 影响钢材性能的因素主要有哪些?答:碳是决定钢材的主要元素,随含碳量增加,钢的强度和硬度将不断提高,而塑性和韧性则会随之下降。硫是一种有害元素,产生“热脆”现象。磷也是一种有害元素,产生“冷脆”现象。锰是一种有益元素,作为脱氧剂和合金元素,减轻硫的有害作用,提高钢的强度和硬度。硅是一种有益元素,作为脱氧剂和合金元素,提高强度,硬度,弹性,降低塑性和韧性。氧,氮:未除尽的氧氮大部分以化合物形式存在,降低强度,冷弯性能和焊接性能。氧增加热脆,氮增加冷脆。钛,钒,铌:钢的强脱氧剂和合金元素,改善韧性,提高强度。 3. 不锈钢有哪些类型?在酸性介质、碱性介质及中性水溶液中是否可以选用同一种不锈钢?简述理由。答:按显微组织为马氏体不锈钢,铁素体不锈钢和奥氏体不锈钢。按化学成分为铬不锈钢和铬镍不锈钢。不可以,因为不同介质溶液中PH值不同,对不锈钢的化学反应都不一样,所以不能用同一种不锈钢,应该有 所针对的选择。 4、高分子材料主要有哪些类型?耐蚀有机高分子有哪些类型?各有什么特点?答:按照化学组分分:碳链有机聚合物、杂链有机聚合物、元素有机聚合物、无机聚合物。常用于水工程及水工艺设备中的高分子材料有:塑料、橡胶、纤维和胶粘剂等。耐蚀有机高分子类型有:热塑性树脂、工程塑料类、热固性树脂等。热塑性树脂中聚乙烯、聚丙烯的应用占主流。工程塑料类虽然有优异的耐腐性能,但因其价格的原因, 在中等的腐蚀环境中首选的仍是价廉易得、加工容易的材料。热固性树脂大多制成复合材料使用。 5.复合材料主要有哪些性能特点? 答:比强度和比刚度高,抗疲劳性能好,减振能力强,高温性能好,断裂安全性高。 精品文档. 精品文档第二章、材料设备的腐蚀、防护与保温 答:氢蚀是指在高温高压环境下,1. 什么叫氢蚀?它对钢的性能有什么影响?氢蚀后使钢材力学性氢进入金属内与一种组分或元素产生化学反应使金属破坏。能下降,强度、塑性下降,呈脆断性破坏、氢蚀一旦发生,便无法消除,是不可逆的。随着腐蚀过程的进行,在多数情什么叫极化?极化对金属腐蚀有什么影响? 2. 金属的腐蚀随极这个现象称为极化,况下,阴极或阳极过程会受到阻滞而变慢, 一、钢铁的冶炼流程和主要设备 一般来说,钢铁的冶炼大致分为四个过程:炼铁、炼钢、热轧、冷轧。 其中我们着重介绍热轧、冷轧的流程和主要设备。 1.热轧 热轧是在钢的再结晶温度以上进行的轧制,轧制过程就是在旋转的轧辊间改变钢坯形状的压力加工过程。热轧时金属塑性高,变形抗力低,大大减少了金属变形的能量消耗。所以热轧能显著降低能耗,降低成本。此外热轧能改善金属及合金的加工工艺性能,即将铸造状态的粗大晶粒破碎,显著裂纹愈合,减少或消除铸造缺陷,将铸态组织转变为变形组织,提高合金的加工性能。 热轧通常采用大铸锭,大压下量轧制,不仅提高了生产效率,而且为提高轧制速度、实现轧制过程的连续化和自动化创造了条件。一般可在带钢热轧机上生产厚度为1.2~8mm 成卷热轧带钢。热轧工艺一般是将连铸的钢板板坯进过加热炉加热到一定温度,经过传送辊道到轧机处进行轧制成带钢、型钢或钢管。带钢还需要经过卷取机卷成钢卷 以便运输。 热轧厂主要设备:加热炉、传送辊道、轧机 (1)加热炉 现在一般采用步进加热炉来加热板坯,以提高自动化程度和生产率。 涉及到的传动产品:链条、轴承、联轴器、电机、减速箱、密封、液压胶管、工业胶管等等。 (2)传送辊道 热轧基本是靠辊道来运输钢坯或带钢。一般有链条传送和棍子传送两种。 涉及到的传动产品:链条、轴承、联轴器、电机、减速箱、密封等等。 (3)轧机 轧机是热轧的关键设备,直接决定了产品质量的好坏。为减少轧辊弹变而影响带钢厚度精度,国内使用的热轧机以四棍或六棍轧机为主。 轧机模型: 涉及到的传动产品:轴承、联轴器、电机、减速箱、密封、液压胶管、工业胶管等等。 (4)冷轧 冷轧是利用热轧钢卷为原料,经酸洗去除氧化皮后进行轧制。冷轧通常采用纵轧(轧辊轴线相平行,旋转方向相反,轧件作直线运动的轧制方法)的方式。冷轧生产的工序一般包括开卷、轧制、脱脂(酸洗)、退火(热处理)、卷取等,生产汽车板还需要镀锌等工艺。 酸洗工艺流程图: 镀锌工艺流程图: 水工艺设备基础考试复 习要点 《水工艺设备基础》复习要 点一考试类型及题型 1)闭卷; 2)单项选择题;填空题;简答题;计算题;论述题(分值有变化,单选和填空分值有所减少) 二知识点 第一章.水工艺设备常用材料 1)掌握水工艺设备常用材料有哪些? 2)了解钢的分类,如按用途分为:结构钢、工具钢和特殊性能钢。 ①按化学成份分类:碳钢和合金钢;A.碳钢按含碳量又可分为:低 碳钢、中碳钢和高碳钢;B.合金钢按含合金元素的含量又可分为:低合金钢、中合金钢和高合金钢;②按照钢中硫和磷的含量又可分为:普通钢、优质钢、高级优质钢;③根据钢的用途又可分为:结构钢、工具钢和特殊性能钢 3)掌握钢的编号的意义:如合金工具钢9SiCr 钢(%);碳素 工具钢 T8表示什么含义?(%) 第二章. 材料设备的腐蚀﹑防护与保 温 1. 材料设备的腐蚀与防护 1)了解什么叫腐蚀及其危害? 2)掌握设备防蚀技术中关于防蚀结构设计需要遵循的基本原则? 3)掌握:a.什么是应力腐蚀及其发生的条件? b.设备防蚀技术中关于改变介质腐蚀特性的途径是什么? 4)重点掌握:a.微生物腐蚀产生的原因及其最常见的微生物腐蚀类型;b.水处理工艺设备常用材料的选择原则? (可能出简答题) 2. 设备的保温 了解设备保温的目的? 第三章水工艺设备理论基 础 1. 容器应力理论 1)掌握什么是薄壁容器?判断标准? 2)了解容器设计的基本要求? 1)工艺要求:容器的总体尺寸、接口管的数目与位置、介质的工作压力、填料种类、规格、厚度等一般都要根据工艺生产的要求通过工艺设计计算及生产经验决定。2)机械设计的要求:(1)容器要有足够的强度(2)要有足够的刚度(3)要具有足够的稳定(4)容器必须有足够的严密性(5)抗腐蚀性和抗冲刷性要好(6)在保证工艺要求、和机械设计要求的基础上,应选择较为便宜的材料,以降低制作成本。(7)确保制作、安转、运输及维护方便。 3)重点掌握圆柱壳薄壁容器的应力计算方法?(记公式、弄懂 实用文档 水工艺设备基础复习参考 一、填空题 1、在水处理工艺中,搅拌器的形式多种多样,应根据工艺要求来选用,常用的搅拌器有:浆式 搅拌器、推进式搅拌器、涡轮搅拌器等。 2、合金工具钢9SiCr钢表示:平均含碳量为0.9%,硅和铬的平均含量小于1.5% 。 3、陶瓷的最大缺点是脆性,它是阻碍陶瓷作为结构材料广泛应用的首要问题,是当前的 重要研究课题。 4、机械性能主要指材料的弹性、塑性、强度和韧性。 5、焊接的方法很多,大体可分为三大类:即熔化焊、压力焊和钎焊。 6、膜组件主要分为板式膜组件、管式膜组件、螺卷式膜组件和中空纤维膜组件。 7、Ni-Mo合金是耐盐酸腐蚀的优异材料。最有名的哈氏合金(0Cr16Ni57Mo16Fe6W4) 能耐室温下所有浓度的盐酸和氢氟酸。 8、机械传动的主要方式有齿轮传动、带传动和链传动。 9、离子交换膜的基本性能交换容量和含水率。 10、物质的导热系数值不仅因物质的种类、结构成分和密度而异,而且还和物质温度、 湿度和压力等因素有关。 11、HSn65-3表示的意义为: 含铜65%、含锡3%的锡黄铜。 12、金属发生应力腐蚀的三个必要条件是:敏感金属、特定介质和一定的静应力。 13、改变介质的腐蚀特性一般有两种途径:一种是去除介质中有害成分;另一种是加缓 蚀剂。 14、吸附装置分为固定床、移动床和流化床。 实用文档 15、通常可将极化的机理分为活化极化、浓差极化和电阻极化。 16、反渗透、超滤、微滤和纳滤设备都是依靠膜和压力来进行分离的。 17、按照化学成分钢主要可分为碳钢和低合金钢。 18、30CrMnSi的意义是:平均碳含量低于0.3%,铬锰硅三种合金元素均小于1.5% 19、金属材料的基本性能是指它的物理性质、化学性质、机械性能和工艺性能。 20、高分子化合物的合成中,最常见的聚合反应有加聚反应和缩聚反应。 21、腐蚀防护设计除正确选材外,具体还包括防蚀方法选择、防蚀结构设计、防蚀强度设 计以及满足防蚀要求的加工方法。 22、按照作用原理不同,电化学保护分为阴极保护和阳极保护。 23、根据缓蚀剂的不同作用特点,缓蚀机理共分为吸附理论、成膜理论、电极过程抑制理 论。 24、金属切削加工分为钳工和机械加工两个部分。 25、热量传递有三种基本方式:热传导、热对流和热辐射。 26、导热过程的单值条件一般有几何条件、物理条件、时间条件和边界条件。 27、凝结换热是蒸汽加热设备中最基本的换热过程。 28、按形状区分,封头分为凸形封头、锥形封头和平板形封头 1.2工艺设备流程概述 1.进棉 人工将原料短纤按比例放在长帘上,由长帘输送到混棉机入口。 2.混棉 2-1 用光电控制进棉机送入的给棉量; 2-2 用光电控制混棉机内的存棉量并定量(厚度或重量)送到开松机入口。3.开松 3-1 喂入部分由给棉机的光电控制来控制喂入量; 3-2 将开松好的原料(短纤)用风机通过物料管道送到给棉机内。 4.给棉 4-1 用光电开关控制从开松机送入的原料(短纤); 4-2 通过斜钉帘上的光电仪来控制送到与梳理机入口的原料(短纤)给入量。 5.预梳理 5-1用变频控制进入量(厚度或重量); 5-2 方法:人工微调变频机速度送到铺网机。 6.铺网机 将进入铺网机的原料经横向纵向交叉折叠5层以上的已铺好的成片状的短纤送入主梳理机。 7.主梳理 7-1 变频控制由铺网机送来的片状短纤; 7-2 经锡林、工作辊、剥取辊将原料(短纤)进行分梳; 7-3 经道夫将原料(短纤)转移到杂乱辊上; 7-4 杂乱辊将纤维打乱增加横向强度 7-5 剥网辊将成型网从杂乱辊上剥离,送到纤网传送帘上(三层复合); 7-6 经切边机切边进入热轧(切下的边料通过风管送到给棉机内)。 8.热轧 将从主梳机进入热轧机上下热辊的片状原料(短纤)通过热辊温度、压力控制(调整对工艺所需要的温度、压力)进行热压成形。 *热辊温度:由加热油炉将热油(235~240℃)经热油泵送入上下热辊。 *热辊压力:由空压机提供的压缩风经调压装置(上压 1.2MPa 下压0.8~ 0.9MPa)进入调压气缸 9.卷绕 将从热轧机出来的产品经切边,计长进行卷绕成卷(成卷最大直径800mm)。 10.成品检验称重 10-1 按产品质量标准取样检测其物理指标; 10-2 每卷产品称重。 11.倒卷 对从卷绕机成卷产品在成卷过程中产生的断头数有要求的需重新进行倒卷并将断头做出标记。 12.包装、入库、出厂 12-1 根据不同产品进行不同的包装,贴标签; 12-2 包装好的产品入库; 12-3 销售出厂。 西安建筑科技大学考试试卷(A)(共3 页) (全日制)班级:姓名:考试科目:水工艺设备基础学号: 评卷人填写 题号一二三四五总分分数 阅卷 人 一填空(共10 分,每空0.5 分) 1 .缓蚀剂必须具备的条件,,。 2 .通常可将极化的机理分为,,。 3 .影响氧去极化腐蚀的因素有,,,。 4 .吸附装置分为,,。 5 .水处理工艺常用的机械搅拌设备有,,。 6 .离子交换膜的基本性能,。 7 .一般认为反渗透膜的透过机理是和。 二选择(共10 分,每题1 分;多选、少选均不得分) 1 .水处理工艺设备发生的腐蚀多属于。 A 局部腐蚀 B 全面腐蚀 C 应力腐蚀 D 微生物腐蚀 2 .可引起循环水系统的金属构件和设备地下管道腐蚀的微生物有。 A 硫酸盐还原菌 B 铁细菌 C 霉菌 D 硫细菌 3 .防止细菌腐蚀可采取的措施。 A 使用杀菌剂或抑菌剂 B 改变环境条件 C 覆盖防护层 D 阴极保护 4 .非金属材料腐蚀主要由引起的。 A 应力作用 B 化学作用 C 微生物作用 D 物理作用 5 .从防腐角度考虑,下列哪种设计较为合理: 6 .下列气浮分离设备应用最广泛的是。 A 微孔布气气浮设备 B 压力溶气气浮设备 C 电解气浮设备 D 射流气浮设备 7 .渗透压与溶液的,和有关,而与无关。 A 膜、浓度、温度、溶液性质 B 浓度、温度、溶液性质、膜 C 、温度、膜、浓度、溶液性质 D 溶液性质、浓度、膜、温度 8 .计量泵流量为Q = F S n 其中S 表示。 A 柱塞断面积 B 冲程 C 时间 D 吸水管断面积 9 .离子交换膜按结构分为。 A 均相 B 半均相 C 复合膜 D 异相膜 10 .发生应力腐蚀的三个必要条件。 A 一定空气湿度 B 敏感的合金 C 特定的介质 D 一定的静应力 三名词解释(共30 分,每题5 分) 1 .老化 2.吸氧腐蚀 3.阴极极化 4.细菌腐蚀 水工艺设备 金属材料是目前水工艺设备材料的主体。 金属材料的特点:良好的塑性和变形性能、导电性和导热性、对光具有良好的反射性能。金属材料的分类: 1.钢:碳钢和低合金刚(化学成分)普通钢和优质钢和高级优质钢(质量)结构钢和工具钢和特殊性能钢(用途) 2.铸铁3:有色金属及其合金 金属材料的基本性能: 1.物理性能:密度大熔点高,热膨胀系数(指材料在温度变化一度时单位长度的伸缩变化值)导热性,导电性和弹性模量(弹性极限内应力和应变的比值)。 机械性能:弹性,塑性,强度(金属材料在外力的作用下抵抗塑性变形和断裂的能力)和韧性(材料对缺口或裂纹敏感程度的反应,用来衡量材料的抗裂纹扩展能力) 工艺过程:可焊性,可锻性,切削加工性,成型工艺性,热处理性。 工艺性能:材料在加工方面的物理化学和机械性能的综合表现构成了材料的工艺性能。 化学性能:耐腐蚀性 不锈钢有哪些类型?在酸性介质、碱性介质及中性水溶液中是否可以选用同一种不锈钢?简述理由。 答:按显微组织为马氏体不锈钢,铁素体不锈钢和奥氏体不锈钢。按化学成分为铬不锈钢和铬镍不锈钢。不可以,因为不同介质溶液中PH值不同,对不锈钢的化学反应都不一样,所以不能用同一种不锈钢,应该有所针对的选择。 化学成分:C钢的主要元素之一,含量增加强度和硬度增加,塑性和韧性减小 S一种有害元素,热加工时容易开裂,“热脆” P一种有害元素,低温时容易变脆,“冷脆” Mn一种有益元素,可以提高钢的强度和硬度 Si一种有益元素,强硬弹增加,塑韧减小。耐蚀,热性增加。 金属材料的耐蚀性能:1.碳钢和铸铁在但水大气土壤海水等中性介质中都不耐腐蚀。 2.在各类干燥气体和有机溶剂等介质中耐蚀性良好。 3.在低浓度碱溶液剂及浓硫酸浓氢氟酸等介质中碳钢和普通铸铁表面能生成稳定的膜。 高分子材料主要有哪些类型?高分子材料主要有哪些性能? 答:按照化学组分分:碳链有机聚合物,杂链有机聚合物,元素有机聚合物,无机聚合物。主要性能有重量轻,高弹性,滞弹性,塑性与受迫弹性好。强度和断裂,韧性,减磨与耐磨性,绝缘性,耐热性,耐蚀性,老化。 10.塑料的组成如何?常用塑料的分类和特点如何? 答:组成:合成树脂,填料,固化剂,增塑剂,稳定剂,润滑剂,着色剂,阻燃剂,其他添加剂。按受热性能分为热塑性塑料:加热时软化,可塑造成型,冷却后则变硬,此过程可反复进行;热固性塑料:初加热时软化,可塑造成型,但固化之后再加热,将不再软化,也不溶于溶剂。按使用范围分通用塑料:应用范围广,生产量大的品种;工程塑料:综合工程性能良好;耐热塑料:能在较高温度下工作。 11. 复合材料主要有哪些性能特点? 答:比强度和比刚度高,抗疲劳性能好,减振能力强,高温性能好,断裂安全性高。热轧工艺流程电子教案

水工艺设备基础

【精品】热轧工艺流程

南通宝钢热轧产线工艺设备基本情况

水工艺设备基础考试复习要点

热轧轧制原理及工艺

水工艺设备基础知识点

1780热轧生产工艺与设备

水工艺设备基础课后习题解答-12页精选文档

水工艺设备基础 期末复习

最新作业-给排水设备工艺黄廷林-主编-课后答案

轧钢工艺过程介绍(介绍的比较详细)

水工艺设备基础考试复习要点完整版

水实用工艺设备基础复习参考

热轧无纺布工艺设备概述

水工艺试题

水工艺设备重点总结