MARLOWET_ECA_10_12_07

MARLOWET ?

ether carboxylic acids

05/2009

SASOL Germany GmbH

Paul-Baumann-Str. 1, D-45764 Marl

Telefon: +49(2365)-49-0 Telefax: +49(2365)-49-2000

info@https://www.sodocs.net/doc/2b12332244.html,

https://www.sodocs.net/doc/2b12332244.html,

1. Product Description

MARLOWET ether carboxylic acids are low foaming anionic surfactants. The products are produced by the carboxymethylation of alkoxylated fatty alcohols. They vary in their alcohol origin and their alkoxylation degree. The products have a high thermal and chemical stability and can be used at any pH. Due to their chemical structure their performance properties range between the typical properties of anionic and non-ionic surfactants. The weak acidic carboxy group allows the modification of the surfactant properties as a function of the pH.

In their application the MARLOWET ether carboxylic acids are typically neutralised with alkanolamines or alkalimetal hydroxide to the corresponding ether carboxylates. Due to their chemical structure these can be regarded as high water soluble soaps. They differ from soaps due to the polyalkylene chain which improves the applications properties such as hard water tolerance, solubility and lubricity.

2. Product Range

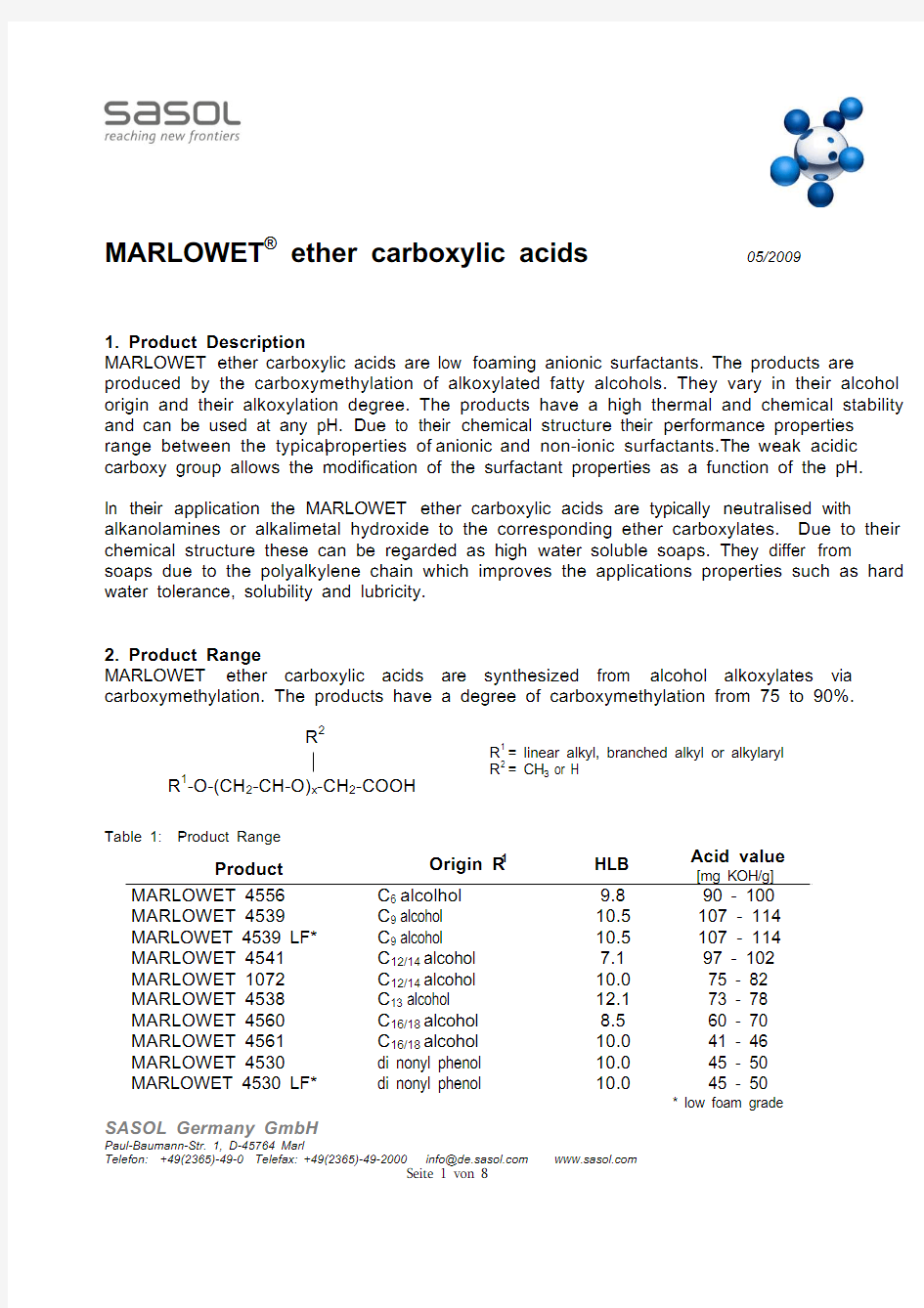

MARLOWET ether carboxylic acids are synthesized from alcohol alkoxylates via carboxymethylation. The products have a degree of carboxymethylation from 75 to 90%.

Table 1: Product Range

Product

Origin R 1 HLB Acid value

[mg KOH/g]

MARLOWET 4556 C 6 alcolhol

9.8 90 - 100 MARLOWET 4539 C 9 alcohol 10.5 107 - 114 MARLOWET 4539 LF* C 9 alcohol 10.5 107 - 114 MARLOWET 4541 C 12/14 alcohol 7.1 97 - 102 MARLOWET 1072 C 12/14 alcohol 10.0 75 - 82 MARLOWET 4538 C 13 alcohol 12.1 73 - 78 MARLOWET 4560 C 16/18 alcohol 8.5 60 - 70 MARLOWET 4561 C 16/18 alcohol

10.0 41 - 46 MARLOWET 4530 di nonyl phenol 10.0 45 - 50 MARLOWET 4530 LF* di nonyl phenol

10.0

45 - 50

* low foam grade

R 1-O-(CH 2-CH-O)x -CH 2-COOH R 2

R 1

= linear alkyl, branched alkyl or alkylaryl R 2 = CH 3 or H

MARLOWET ?

ether carboxylic acids

05/2009

SASOL Germany GmbH

Paul-Baumann-Str. 1, D-45764 Marl

Telefon: +49(2365)-49-0 Telefax: +49(2365)-49-2000

info@https://www.sodocs.net/doc/2b12332244.html,

https://www.sodocs.net/doc/2b12332244.html,

3. Application

Table 2: Examples of typical applications

Product

Main Application

MARLOWET 4556 wetting agent in formulations with high electrolyte load or high alkalinity; solubilizer for electroplating processes, alkaline cleaners

MARLOWET 4539 Co-emulsifier and corrosion inhibitor for water based metal working fluids, wetting agent in high alkaline medium, electroplating, alkaline emulsion cleaner MARLOWET 4539 LF co-emulsifier in foamless water based metal working fluids and emulsions

MARLOWET 4541 co-emulsifier and corrosion inhibitor in water based metal working fluids, alkaline emulsion cleaner MARLOWET 1072 multi purpose wetting agent e.g. for textile auxiliaries MARLOWET 4538 multi purpose wetting agent e.g. for textile auxiliaries MARLOWET 4560 water soluble lubricant, cutting fluids, co-emulsifier, leather auxiliaries

MARLOWET 4561

water soluble lubricant, cutting fluids, co-emulsifier or leather auxiliaries

MARLOWET 4530 emulsifier for naphthenic base oils, co-emulsifier in water based metal working fluids

MARLOWET 4530 LF co-emulsifier in foamless water based metal working fluids and emulsions

MARLOWET ?

ether carboxylic acids

05/2009

SASOL Germany GmbH

Paul-Baumann-Str. 1, D-45764 Marl

Telefon: +49(2365)-49-0 Telefax: +49(2365)-49-2000

info@https://www.sodocs.net/doc/2b12332244.html,

https://www.sodocs.net/doc/2b12332244.html,

3.1 Corrosion inhibition

Formulations for metal working applications require a sufficient corrosion inhibition effect to protect the metal surfaces from corrosion damage. Especially MARLOWET 4539 and the low foaming MARLOWET 4539 LF grade provide a balanced corrosion inhibition effect for the metal working fluids at low alkalinities.

Often the combination of MARLOWET ethercarboxylic acids as co-emulsifiers for oleic acid or fatty acid poly glycol esters provide good corrosion protection for the metal parts. A good combination for nitrogen free metal working fluids is the combination of MARLOWET 4541 and the soy bean oil ethoxylate MARLOWET 4750 M.

MARLOWET ethercarboxylic acids have a very low electrolyte content in the range of 0.1-0.5 weight -% which favour them, in comparison to other anionic emulsifiers, for application which are sensitive for corrosion.

3.2 Hard water stability and lime soap dispersing properties

MARLOWET ether carboxylic acids are efficient dispersants for lime soaps. These are formed whenever fatty acids are used as a base surfactant or emulsifier in applications where hard tap water is used. The ether carboxylic acids inhibit the formation of precipitates of calcium and magnesium soaps. The calcium and magnesium salts of the MARLOWET ether carboxylic acids are in itself liquid and provide excellent dispersing properties stabilizing the calcium or magnesium soaps. Figure 1 demonstrates this function by means of the dynamic surface tension. With oleic acid alone the addition of calcium hardness ions results in a precipitate of calcium oleate and an increase of the surface tension to the same value of water. In the case of solutions comprising MARLOWET ethercarboxylic acid, the calcium salts remain dispersed in the solution and still provide sufficient surface activity. A solution of oleic acid with MARLOWET 4539 in a ratio of 3:1 shows a dynamic surface tension of 41 mN/m at a water hardness of 50° dH (890 ppm CaCO 3).

MARLOWET ?

ether carboxylic acids

05/2009

SASOL Germany GmbH

Paul-Baumann-Str. 1, D-45764 Marl

Telefon: +49(2365)-49-0 Telefax: +49(2365)-49-2000

info@https://www.sodocs.net/doc/2b12332244.html,

https://www.sodocs.net/doc/2b12332244.html,

Figure 1: Dynamic

surface tension of soap mixtures with

MARLOWET products

3.3 Temperature- and pH-stability

The MARLOWET products possess a high thermal and chemical stability and can be used in a wide range of pH values ranging from 3 to 14. Due to their properties they are often used in combination with non-ionic surfactants to improve the temperature and electrolyte stability.

Figure 2: left - non stabilized emulsion

right - Emulsion stabilized with MARLOWET 4539

o l e

i c

a c i

d M A R L O W E T 4556M A R L O W E T 4560M A R L O W E T 4539

M A R L O W E T 4541

102030405060

70

80

o l e i c a c i d +o l e i c a c i d +o l e i c a c i d +o l e i c a c i d S u r f a c e t e n s i o n [m N /m ]

MARLOWET ?

ether carboxylic acids

05/2009

SASOL Germany GmbH

Paul-Baumann-Str. 1, D-45764 Marl

Telefon: +49(2365)-49-0 Telefax: +49(2365)-49-2000

info@https://www.sodocs.net/doc/2b12332244.html,

https://www.sodocs.net/doc/2b12332244.html,

020406080100120140160w e t t i n g t i m e c o t t o n [s ]

concentration NaOH [weight %]

In processes with a high electrolyte content, for example in galvanic applications, metal working fluids or high alkaline cleaners, ether carboxylic acids are ideal emulsifiers. For this purpose short chained ether carboxylic acids with high acid values show the best results e.g. MARLOWET 4556.

Figure 3: MARLOWET electrolyte stability

through determination of wetting efficiency in

comparison to non-ionic surfactant MARLIPAL O13/60

MARLOWET ?

ether carboxylic acids

05/2009

SASOL Germany GmbH

Paul-Baumann-Str. 1, D-45764 Marl

Telefon: +49(2365)-49-0 Telefax: +49(2365)-49-2000

info@https://www.sodocs.net/doc/2b12332244.html,

https://www.sodocs.net/doc/2b12332244.html,

4.3 Foam Supression

An important feature in technical applications where surface active substances are involved is foam suppression. In emulsions such as water soluble cooling lubricants the MARLOWET ether carboxylic acid LF (for Low Foam) grades reduce efficiently foam formation at pH values of above 8, therefore preventing foaming problems in the circulated systems of removing fluids.

Figure 4:

metal working application

4.4 Lubrication

The ethercarboxylic acids based on long chain alcohols provide excellent gliding and lubricating properties for aqueous metal working and leather applications. The products contain a very low content of mineral acid ions like chloride or sulphate and build, in contrast to other lubricants, no hard encrustations even after extended use. The products are used in metal treatment, water based lubricating systems or in textile auxiliaries.

Low friction rates and fatty acid stabilizing properties are achieved by MARLOWET 4560 or MARLOWET 4561 and their corresponding alkali metal hydroxide salts. This performance is often required in water based lubricants for example in semi synthetic cutting fluids or in applications such as lubricating surfactants where oily substances are not acceptable.

MARLOWET ?

ether carboxylic acids

05/2009

SASOL Germany GmbH

Paul-Baumann-Str. 1, D-45764 Marl

Telefon: +49(2365)-49-0 Telefax: +49(2365)-49-2000

info@https://www.sodocs.net/doc/2b12332244.html,

https://www.sodocs.net/doc/2b12332244.html,

4. 5 Recipe Guide

Metal working fluid base formulation

Mineral oil 67% Fatty acid 12% MARLOX RT 42 8% MARLON AS3 acid 6% MARLOWET 4539 3% Alkanolamine 4%

Application concentration: about 3 to 5%

Metal working fluid base formulation, nitrogen free

Mineral oil 33% Phenoxyethanol 12% Fatty acid 12% Petrolsulphonate 5% Fatty acid, dimer 7% MARLOWET 4750 M 7% MARLOWET 4541 4% Butyldiglycol 7% Caustic potash (45%) 13%

Application concentration: about 3 to 5%

Heavy soiling cleaner

Solvent 20% MARLIPAL O13/40 4% MARLOWET 4539 LF 1% Caustic soda 1% Water 74%

stable against alkaline and temperature, low foam application

MARLOWET ?

ether carboxylic acids

05/2009

SASOL Germany GmbH

Paul-Baumann-Str. 1, D-45764 Marl

Telefon: +49(2365)-49-0 Telefax: +49(2365)-49-2000

info@https://www.sodocs.net/doc/2b12332244.html,

https://www.sodocs.net/doc/2b12332244.html,

5. Transport and Storage

MARLOWET ether carboxylic acids can be delivered in road tankers or in plastic drums. The products can be stored in stainless steel vessels (steel no.: 14541 or 1.4571).

Most of the products are homogenous liquids at room temperature. MARLOWET 4560 and MARLOWET 4561 have a solidification point around room temperature. These two products must be heated to above 30°C and homogenised before removal from the container.

Please refer to the individual product data sheets which are available on request for further information about the specification and physical data.

6. Safety and Handling

Sasol is committed to the Responsible Care? initiative.

Please refer to the individual material safety data sheets for specific, complete information regarding the safe handling, health and environmental effects of our MARLOWET ether carboxylic acids.