页岩气介绍(A guide to shale gas 2011)

An introduction to shale gas June 2011

Shale Gas vs Conventional Gas

Natural gas resources are typically divided into two categories: conventional and unconventional. Conventional gas typically is found in reservoirs with permeabilities greater than 1 millidarcy (“mD”) and can be extracted via traditional techniques. A large proportion of the gas produced globally to date is conventional, and is relatively easy and inexpensive to extract. In contrast, unconventional gas is

found in reservoirs with relatively low permeabilities (less than 1 mD) and hence cannot be extracted via conventional methods.

There are several types of unconventional gas resources that are produced today but the three most common types are tight gas, coal bed methane and shale gas. Given the low permeability of these reservoirs, the gas must be developed via special techniques including fracture stimulation (or “fraccing”) in order to be produced commercially.

Shale Play Properties

Shale gas is natural gas that is produced from a type of sedimentary rock derived from clastic sources often including mudstones or siltstones, which is known as shale. Clastic sedimentary rocks are composed of fragments (clasts) of pre-existing rocks that have been eroded, transported, deposited and lithified (hardened) into new rocks. Shales contain organic material which was lain down along with the rock fragments.

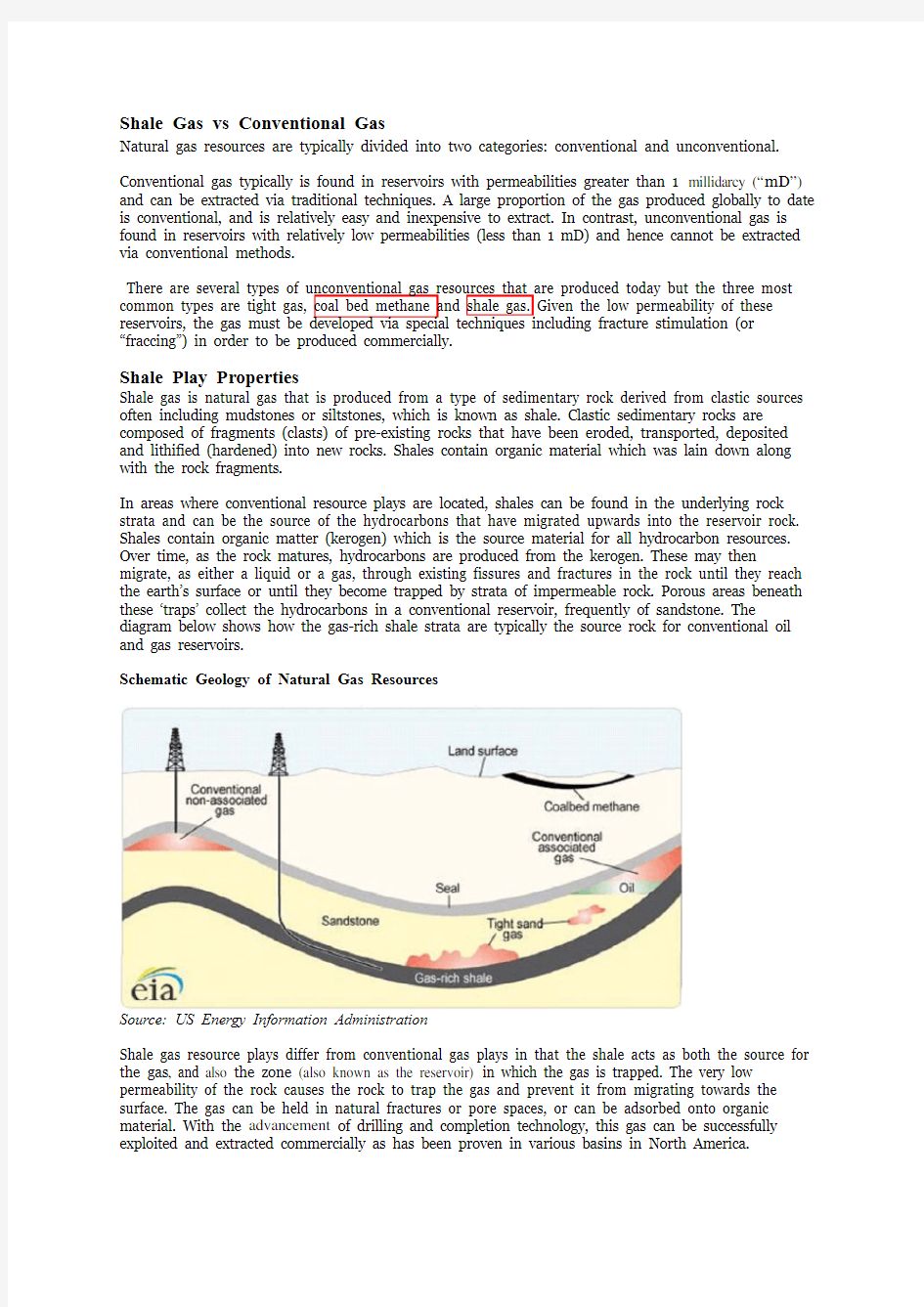

In areas where conventional resource plays are located, shales can be found in the underlying rock strata and can be the source of the hydrocarbons that have migrated upwards into the reservoir rock. Shales contain organic matter (kerogen) which is the source material for all hydrocarbon resources. Over time, as the rock matures, hydrocarbons are produced from the kerogen. These may then migrate, as either a liquid or a gas, through existing fissures and fractures in the rock until they reach the earth’s surface or until they become trapped by strata of impermeable rock. Porous areas beneath these ‘traps’ collect the hydrocarbons in a conventional reservoir, frequently of sandstone. The diagram below shows how the gas-rich shale strata are typically the source rock for conventional oil and gas reservoirs.

Schematic Geology of Natural Gas Resources

Source: US Energy Information Administration

Shale gas resource plays differ from conventional gas plays in that the shale acts as both the source for the gas, and also the zone (also known as the reservoir) in which the gas is trapped. The very low permeability of the rock causes the rock to trap the gas and prevent it from migrating towards the surface. The gas can be held in natural fractures or pore spaces, or can be adsorbed onto organic material. With the advancement of drilling and completion technology, this gas can be successfully exploited and extracted commercially as has been proven in various basins in North America.

Aside from permeability, the key properties of shales, when considering gas potential, are total organic content (“TOC”) and thermal maturity. TOC is the total amount of organic material (kerogen) present in the rock, expressed as a percentage by weight. Generally, the higher the TOC, the better the potential for hydrocarbon generation. The thermal maturity of the rock is a measure of the degree to which organic matter contained in the rock has been heated over time, and potentially converted into liquid and/or gaseous hydrocarbons. Thermal maturity is measured using vitrinite reflectance (Ro).

Because of the special techniques required for extraction, shale gas can be more expensive than conventional gas to extract. On the other hand, the in-place gas resource can be very large given the significant lateral extent and thickness of many shale formations. However, only a small portion of the world’s shale gas is theoretically producible and even less likely to be producible in a commercially viable manner. Therefore a key determinant of the success of a shale play is whether, and how much, gas can be recovered to surface and at what cost.

The Rise of Shale Gas in the US

Shale gas technology has been largely pioneered in the US and the emergence of US shale gas plays has fundamentally altered the US natural gas supply picture.

The first shale gas well in the US commenced production in 1821 from a well near Fredonia, New York. Low level s of shale gas production occurred between this period and the year 2000 and it has only really been since 2006 that the shale gas industry in the US has started to gain significant momentum.

Overview of Key US Shales

The figure below shows an overview of the key US shale plays. Whilst the distribution of oil and gas bearing shales across the US subsurface is much larger than shown in the map, only a relatively small number of these are currently being developed.

US Shale Gas plays

The chart below shows the estimated volumes of technically recoverable resources in four of the leading US shale plays compared with some of the world’s largest conventional gas fields (Source: Chesapeake—2010 Institutional Investor and Analyst Meeting, 13/10/2010). The Marcellus shale and the Haynesville shale stand out as two of the three largest known gas resources in the world.

Comparison of us shales and global conventional gas resources

Source: Chesapeake—2010 Institutional Investor and Analyst Meeting, 13/10/2010 (slide 47)

Gas Shale Challenges and Solutions

As mentioned earlier the gas storage properties of shales are quite different to conventional reservoirs. In addition to having gas present in the matrix system of pores similar to that found in conventional reservoir rocks, shales also have gas bound or adsorbed to the surface of organic materials in the shale. The relative contributions and combinations of free gas from matrix porosity and from desorption of adsorbed gas is a key determinant of the production profile of the well.

The amount and distribution of gas within the shale is determined by, amongst other things, the initial reservoir pressure, the petrophysical properties of the rock, and its adsorption characteristics. During production there are three main processes at play. Initial gas production is dominated by depletion of gas from the fracture network. This form of production declines rapidly due to limited storage capacity. After the initial decline rate stabilises, the depletion of gas stored in the matrix becomes the primary process involved in production. The amount of gas held in the matrix is dependent on the particular properties of the shale reservoir which can be hard to estimate. Secondary to this depletion process is desorption whereby adsorbed gas is released from the rock as pressure in the reservoir declines. The rate of gas production via the desorption process depends on there being a significant drop in reservoir pressure.

Pressure changes typically advance through the rock very slowly due to low permeability. Tight well spacing can therefore be required to lower the reservoir pressure enough to cause significant amounts of adsorbed gas to be desorbed.

These overlapping production processes result in the characteristic hyperbolic production profile that declines sharply (typically by 60-80 per cent.) over the first year. The diagram below shows how production rates for shale wells in four plays in the US vary over time

US Shale Gas plays

0.0

2.04.06.08.010.012.0

1

2

3

4

567

8

9

10

End of Year

P r o d u c t i o n R a t e (m m c f e /d )

Source: Chesapeake—2010 Institutional Investor and Analyst Meeting, 13/10/2010 (slide 54)

Due to these particular properties, the ultimate recovery of the gas in place surrounding a particular shale gas well can be in the order of 28-40 per cent. (whereas the recovery per conventional well may be as high as 60-80 per cent.). The development of shale gas plays, therefore, differs significantly from the development of conventional resources. With a conventional reservoir, each well is capable of draining oil or gas over a relatively large area (dependent on reservoir properties). As such, only a few wells (normally vertical) are required to produce commercial volumes from the field. With shale gas projec ts, a large number of relatively closely spaced wells are required to produce large enough volumes to make the plays economic.

As a result, many wells must be drilled in a shale play to drain the reservoir sufficiently. In the Barnett play in the US, the drilling density can exceed one well per 60 acres.

Key Shale Gas Production Techniques

As stated earlier, shales have very low permeability (measured in nanodarcies). As a result of this, many wells are required to deplete the reservoir, and special well design and well stimulation techniques are required to deliver production rates of sufficient levels to make a development

economic. Horizontal drilling and fracture stimulation have both been crucial in the development of the shale gas industry.

Horizontal Drilling

Horizontal drilling is a technique that allows the wellbore to come into contact with significantly larger areas of hydrocarbon bearing rock than in a vertical well. As a result of this increased contact,

production rates and recovery factors can be increased. As the technology for horizontal drilling and fraccing has improved, the use of horizontal drilling has increased significantly. In the Barnett shale in the US, for example, the number of horizontal wells drilled in 2001-03 was 76. In 2007-08 this number had risen to 1,810. Over the same interval, the number of new vertical wells in the Barnett declined from 2,001 to just 131.

Hydraulic Fracture Stimulation

Hydraulic fracture stimulation, or “fraccing”, is a process through which a large number of fractures are created mechanically in the rock, thus allowing the natural gas and/or crude oil trapped in

subsurface formations to move through those fractures to the wellbore from where it can then flow to the surface. Fraccing can both increase production rates and increase the total amount of gas that can be recovered from a given volume of shale. Pump pressure causes the rock to fracture, and water carries sand (“proppant”) into the hydraulic fracture to prop it open allowing the flow of gas. Whilst

water and sand are the main components of hydraulic fracture fluid, chemical additives are often added in small concentrations to improve fracturing performance.

Pad Drilling

In shale drilling it is becoming increasingly common to use a single drill pad to develop as large an area of the subsurface as possible. One surface location may be used to drill multiple wells. Pad drilling increases the operational efficiency of gas production and reduces infrastructure costs and land use. Any negative impact upon the surface environment is therefore mitigated.

Stacked Wells

The drilling of stacked horizontal wells may be possible where the shale is sufficiently thick or multiple shale rock strata are found layered on top of each other. One vertical well bore can be used to produce gas from horizontal wells at different depths. One area where this technology is being employed is in the Pearsall and Eagle Ford plays in southern Texas. Cost savings and efficiencies can be achieved as surface facilities are shared. As in pad drilling, the environmental impact on the surface is mitigated as a result of reduced land use. This technology can be particularly beneficial in the thicker shales.

Multilateral Drilling

Multilateral drilling is similar to stacked drilling in that it involves the drilling of two or more horizontal wells from the same vertical well bore. With multilateral drilling, the horizontal wells access different areas of the shale at the same depth, but in different directions. With the drilling of multilateral wells it is possible for production rates to be increased significantly for a reduced incremental cost.

The diagrams below show examples of pad drilling (Source: Tyndall Centre Report—Shale Gas: A Provisional Assessment of Climate Change and Environmental Impacts, January 2011) and multi-lateral wells (Source: Baker Hughes INTEQ).

Pad drilling Multi-lateral drilling

Benefits of Technology Improvements

Decline in Drilling Costs

Due to the extensive reliance on horizontal drilling and hydraulic fracturing, the costs associated with the development of shale resources can be significantly higher than for conventional oil and gas. However, these costs have been driven down over the past decade in North America due to efficiency improvements resulting from large scale drilling programmes and the use of pad drilling and stacked or multilateral wells. Thus, Chesapeake Energy reported achieving significant improvements in drilling times and costs in the Barnett shale in 2010. The graph below shows improvements in drilling times and costs achieved by Encana in the Piceance Basin from 2006 to 2010.

Development of Piceance Shale Development of Piceance Shale

Days to Drill Drilling Cost

Source: Encana—Division Overview March 2010

Decline Mitigation and Increased Recovery

A combination of improved technology and shale-specific experience has also led to improvements in recovery factors and reductions in decline rates. Each shale play requires its own specific completion techniques, which can be determined through careful analysis of rock properties. The correct selection of well orientation, stimulation equipment, fracture size and fraccing fluids can all affect the performance of a well.

The initial production (“IP”) rate from a particular well is highly dependent on the quality of the frac and the well completion. In the US it has been seen that IP rates have been augmented over time as the play matures (see below in the Haynesville). IP rates can be increased by several techniques, in particular by increasing the number of frac stages and increasing the number of perforations per frac stage. The quality of the frac is also improved as fluid properties are developed. Microseismic data can also be used to improve the efficiency of the fraccing process.

Development of Haynesville IP Rate

Source: Chesapeake Energy—2010 Investor and Analyst Meeting Presentation

For developed shales in North America the combined benefits of improved technology and increased experience have resulted in the upward shift of well type curves (expected well production curves) over time. Both the expected ultimate recovery per well and the peak production per well have been seen to increase as plays have matured.

Environmental Considerations

Water Usage and Recycling

A large volume of water is needed for the development of shale gas plays. Water is used for drilling, where it is mixed with clays to form drilling mud. This mud is used to cool and lubricate the drill-bit, provide well-bore stability and also carry rock cuttings to the surface.

Water is also used in significant volumes in hydraulic fracturing. In addition to water and sand, a small concentration of other additives is added to the fluid to improve fraccing efficiency. Chesapeake Energy cites a figure of 4.5 million gallons of fluid for the fracturing of a typical horizontal well. This significant volume of water needs a plentiful source. In the US, the water is typically trucked to the drilling location or transported via temporary pipelines.

A typical fraccing fluid

Source: Chesapeake—Hydraulic Fracturing Fact Sheet

A typical fraccing fluid is more than 98 per cent. water and sand. The other 2 per cent. is made up of a number of additives which may vary depending on the particular well and operator (Source: Chesapeake—Water Use Fact Sheet). Typically additives include many substances that are commonly found in small measure in various household products. The range of additives shown in the diagram above, and the purpose of each, is set out in the table below.

Product Purpose Downhole result Other common

uses

Water and

Sand: >98%

Water Expand fracture and

deliver sand Some stays in formation while remainder returns

with natural formation water as “produced water”

(actual amounts returned vary from well to well).

Landscape,

manufacturing

Sand Proppant Allows the fractures to

remain open so the gas

can escape Stays in formation, embedded in fractures (used to

“prop” fractures open).

Drinking water

filtration, play sand,

concrete and

brick mortar

Other additives: <2%

Acid Helps dissolve minerals

and initiate cracks in the

rock Reacts with minerals present in the formation to

create salts, water, and carbon dioxide

(neutralised).

Swimming pool

chemical and cleaner

Corrosion Inhibitor Prevents the corrosion of the

pipe

Bonds to metal surfaces (pipe) downhole. Any

remaining product not bonded is broken down by

microorganisms and consumed or returned in

produced water.

Pharmaceuticals,

acrylic fibres and

plastics

Iron Control Prevents precipitation of

metal (in pipe)Reacts with minerals in the formation to create

simple salts, carbon dioxide and water all of which

are returned in produced water.

Food additive; food

and beverages; lemon

juice

Anti-Bacterial Agent Eliminates bacteria in the

water that produces

corrosive byproducts

Reacts with micro‐organisms that may be present

in the treatment fluid and formation. These micro‐

organisms break down the product with a small

amount of the product returning in produced

water.

Disinfectant; steriliser

for medical and

dental equipment

Scale Inhibitor Prevents scale deposits

downhole and in surface

equipment Product attaches to the formation downhole. The

majority of product returns with produced water

while remaining reacts with micro‐organisms that

break down and consume the product.

Household cleansers,

deicer, paints, and

caulk

Clay Stabliser Prevents formation clays

from swelling Reacts with clays in the formation through a

sodium—potassium ion exchange. Reaction

results in sodium chloride (table salt) which is

returned in produced water.

Low‐sodium table salt

substitute, medicines,

and IV fluids

Friction reducer “Slicks” the water to minimise

friction Remains in the formation where temperature and

exposure to the “breaker” allows it to be broken

down and consumed by naturally occurring micro‐

organisms. A small amount returns with produced

water.

Cosmetics including

hair, make‐up, nail

and skin products

Surfactant Used to increase the viscosity

of the fracture fluid Generally returned with produced water, but in

some formations may enter the gas stream and

return in the produced natural gas.

Glass cleaner,

multisurface

cleansers,

antiperspirant,

deodorants and

haircolour

Gelling Agent Thickens the water in order

to suspend the sand Combines with the “breaker” in the formation

thus making it much easier for the fluid to flow to

the borehole and return in produced water.

Cosmetics, baked

goods, ice cream,

toothpaste, sauces,

and salad dressings

Breaker Allows a delayed break down

of the gel Reacts with the “crosslinker” and “gel” once in the

formation making it easier for the fluid to flow to

the borehole.

Reaction produces ammonia and sulphate salts

which are returned in produced water.

Hair colouring, as a

disinfectant, and in

the manufacture of

common household

plastics

Crosslinker Maintains fluid viscosity as

temperature increases Combines with the “breaker” in the formation to

create salts that are returned in produced water.

Laundry detergents,

hand soaps and

cosmetics

pH Adjusting Agent Maintains the effectiveness of

other components, such as

crosslinkers

Reacts with acidic agents in the treatment fluid to

maintain a neutral (non‐acidic, non‐alkaline) pH.

Reaction results in mineral salts, water and carbon

dioxide which is returned in produced water.

Laundry detergents,

soap, water softener

and dish washer

detergents

Source: Chesapeake—Water Use Fact Sheet

the target zones and then forced deep into the targeted shale gas formations. In order to minimise the risk of any groundwater contamination, good drilling practice normally requires that one or more strings of steel casing are inserted into the well and cemented into place so as to ensure that the entire wellbore, other than the production zone, is completely isolated from the surrounding formations including aquifers. Most oil or gas-bearing shales in the US tend to be at least 1,500m below the surface, whereas aquifers are generally no more than 500 metres below the surface.

Given the thickness of rock separating target shale formations from overlying aquifers, and the extremely low permeability of shale formations themselves, and also assuming the implementation of good oilfield practices (such as casing and cementing), it is considered by the industry that the risk of contamination of overlying aquifers as a result of hydraulic fracturing operations is remote. Instances where contamination of aquifers has been alleged are generally believed to have involved poor drilling practices, in particular poor casing and cementing of a well or poor construction of surface storage facilities.

Currently, most of the flowback fluid from fraccing operations is either transported from well sites for disposal or is processed for re-use in further operations. Suspended solids must be removed from the water before re-use. The recycling of this water can be costly and is a major focal point of many environmental groups and environmental regulators. New, more efficient, technologies have been developed which allow frac fluid to be recycled on-site at reduced cost.

Fluids other than water may be used in fraccing processes, including CO2, nitrogen or propane, although their use is currently much less widespread than water.

The Shale Gas Industry in Poland

The Emergence of Shale in Europe

Following on from the dramatic advances in shale hydrocarbons technology and shale oil and gas production in the US, a number of oil and gas companies have started to look for opportunities to apply the techniques developed in North America in new geological basins and markets outside North America. A considerable number of regions around the world have been the focus of interest for their shale potential. In a report commissioned by the US Energy Information Agency ‘World Gas Shale Resources: An Initial Assessment of 14 Regions Outside the United States’ published by the EIA in April 2011 (the “EIA Report”), 48 major shale basins are identified in 32 countries around the world.

48 Major Shale Basins in 32 countries

Source: EIA

The EIA Report identifies a number of plays across Europe where organic-rich shales are present, including:

I.Lower Paleozoic shales, spreading from Eastern Denmark and Southern Sweden to Northern

and Eastern Poland;

II.Carboniferous shales, spreading from North-West England through Netherlands and North-West Germany to South-West Poland; and

III.Lower Jurassic bituminous shales, spreading from the South of England to the Paris Basin in France, the Netherlands, Northern Germany and Switzerland.

The EIA Report further identifies Poland and France as countries with some of the largest estimated shale gas technically recoverable resources in Europe. Both countries are also highly dependent on imported gas to meet domestic demand.

Shale in Poland

Of the various European shale plays, Poland is among the most advanced in terms of exploration for and appraisal of unconventional gas resources.

The shales are deposited in three basins—the Baltic in the north, the Lublin in the south, and the Podlasie in the east (see map below). The organically rich shales in these three basins appear to have favourable characteristics for shale gas exploration.

Major Shale Basins of Poland

Source: Advanced Resources International, Inc. / EIA

The EIA Report estimates that Poland has 792 TCF of risked shale gas-in place, comprising 514 TCF in the Baltic Basin, 222 TCF in the Lublin Basin and 56 TCF in the Podlasie Basin. The EIA Report estimates a risked technically recoverable shale gas resource of 187 TCF from these three basins.

The 8,846 square mile shale gas prospective area in the Baltic Basin was determined by the EIA Report using the depth and thermal maturity of the Llandovery Formation. The formation shallows to the northwest, where its prospective area is limited by lack of sufficient thermal maturity. In the deep, western margin of the basin, the Llandovery Formation is highly thermally mature, values greater than 5.0 per cent. However, the basin becomes very deep in this area. In the western areas, the prospective area is limited by the 5,000 metres depth contour interval.

Onshore Baltic Basin, Lower Silurian Llandovery shale depth and structure

Entry of Major Players in Recent Years

One of the first organisations to recognise the potential of shale gas in Poland was the 3 Legs Resources Group. Following the entry of 3Legs Resources Group, there was a rapid take up of acreage in 2009 and 2010 both by smaller exploration and production companies, and by some of the major international companies including ExxonMobil, ConocoPhillips, Chevron, Marathon Oil, Eni and Total.

As at the date of this note, exploration drilling is being either contemplated or carried on by these organisations. Only when this work has been carried out will the true potential of Polish shales be understood.

June 2011.

北美页岩油气产区介绍

北美页岩油气产区介绍美国非常规油气藏、尤其是页岩气的开发,极大增加了美国国内的天然气库存。但是,以天然气为主的页岩区带,如成功开发的Fayetteville和Barnett页岩区带,现在已经不再是人们关注的焦点,但其中的湿气(天然气液化物和油)仍然炙手可热。一些高产的页岩区带,如横跨宾州至纽约的Marcellus区带中的天然气液化物和油的含量都非常丰富。 1.Avalon页岩区带 Avalon页岩区带位于二叠盆地最西部的Delaware盆地,Avalon页岩上覆在Bone Spring地层之上。Avalon-Bone Spring 页岩区带有时简称为Avalon页岩区带。人们曾经钻穿过该页岩层以寻找其它的油气藏,但Avalon页岩的潜力在一段时间内都没有被人们认识到。在有些地方,Avalon和Bone Spring 页岩被一层灰岩分隔开。一位不再对此区带感兴趣的作业公司表示,该页岩区带含有原油、天然气液化物和残余气。 2.Bakken页岩区带 Bakken油页岩区带在蒙大拿和北达可它州一直是油页岩时代的一颗新星,它被人们看作是下一个沙特。广泛分布的上泥盆系—下密西西比系Bakken地层由三个小层段组成:上部页岩段、下部页岩段及含硅质碳酸盐岩的中部层段。其中,中Bakken层是钻井的主要目标层,该层的深度大约10000英尺,

直井钻至该深度前就开始转成水平,进入易碎的白云岩层并在其中进行多段分段压裂,以便进行开始更高效的生产。Bakken 页岩区带一直延伸到加拿大的萨斯喀彻温省和马尼托巴湖地区,这些地方的Bakken页岩也具有产能。 3.Barnett Combo页岩区带 Barnett Combo页岩位于德州的Montague县和Cooke县。该区带中的生油窗非常清晰,Barnett Combo页岩位于著名的密西西比Barnett页岩区带中,但是作业公司却通常选择该区带中的天然气区块。Combo区带实际上同时产油、产气和天然气液化物。该区块每平方英里的地质储量的范围4000万桶到2亿桶油当量之间,是世界上最大的区带之一。该区块已经钻了很多直井,并且直井的生产历史都比较长。 4.Cana Woodford页岩区带 Cana Woodford页岩区带位于美国西奥克拉何马,据报道,该地区已经成为相当大的油页岩区带。据Devon能源公司的数据,密西西比系的Cana页岩是世界上最深的页岩区带,其垂直真深度在11500英尺到14500英尺之间,地层中部深度为16700英尺到19000英尺之间。 Cana Woodford页岩比其东边的Arkoma Woodford 页岩要深不少,其钻到的价格也比较贵。但由于其中含有大量的凝析油和其他价值不菲的液态烃,该区带被人们认为是世界上最具

美国页岩气开发情况的分析

美国页岩气开发情况的分析 美国页岩气的快速发展为世人瞩目,对美国乃至全球的能源格局形成了不容忽视的影响。在此我们进行介绍,以期对我国页岩气产业的发展提供借鉴。 页岩气是从页岩层中开采出来的天然气,它与煤层气、致密砂岩气一起,被称为非常规油气资源的三大品种。相对常规天然气而言,页岩气实际上是原生原储的天然气贫矿。有一个形象的说法,常规天然气好比是“大金娃娃”,页岩气相对富集的地质块体不过是“甜点”。就是这种贫矿,十年前美国的开采还微不足道,而现在已占美国天然气开采总量的约1/4,一场页岩气开发热潮正在美国上演。而且,页岩气的开发也在深刻影响着美国的能源利用和应对气候变化行动。 美国页岩气开发现状 美国是世界上最早进行页岩气资源勘探开发的国家,开采历史可以追溯到1821年。但是,页岩致密低渗的特点导致页岩气开采难度大、成本高,在本世纪以前,页岩气大规模开发并不具有经济上的可行性。随着水平井技术和水力压裂技术的成熟,开采成本大幅下降,页岩气的商业化开发具备了可行性。 近年来美国页岩气勘探开发的发展速度惊人。2004年,美国页岩气井仅有2900口,2005年不过3400口,2007年暴增 至41726口,到2009年,页岩气生产井数达到了98590口。而且,这种增长势头还在继续保持,2011年仅新建页岩油气井数就达到了10173口。 美国页岩气的大开发,提高了美国能源自给水平,美国能源对外依存度降至20世纪80年代以来最低水平。美国石油进口从2005年占石油总消费量的60%下降到2012年的42%,净进口量从1300多万桶/天降至800万桶/天。而且,美国60年来首次成为炼油产品出口国,美国在2009年已经超越俄罗斯成为最大的天然气生产国。国际能源署在2012年11月份发布一份十分乐观的预测:在2017年将超过沙特成为最大的石油生产国,到2035年美国将实现能源自给自足。 美国页岩气开发热潮出现的原因 北美大陆页岩气储量丰富。2013年,由美国能源信息署组织的研究团队对世界41个国家、137个页岩气沉积盆地进 行了全球页岩气评估。结果显示,全球页岩气技术可采资源量为206.68万亿立方米,与常规天然气探明可采储量相当。其中,北美洲页岩气资源最为丰富,占全球总量的23.4%。按照国家分布情况,美国页岩气技术可采资源量为18.8万亿立方米,位居世界第四。

2019年中美页岩气发展对比及中国对页岩气产业的政策支持

2019年中美页岩气发展对比及中国对页岩气产业的政策支持

目录 1.盈利预测与投资建议: (5) 1.1.盈利预测与估值 (5) 1.2.投资建议及公司分析:维持行业增持评级 (5) 2.非常规气包括煤层气、页岩气、致密气等,其中页岩气主要集中于西南及鄂尔多斯地区 (7) 2.1.煤层气属于煤的伴生资源,通过压裂技术实现增产 (9) 2.2.页岩气开发由于递减快等原因需要高投入形成规模化效应 (10) 2.3.致密气主要分布在鄂尔多斯盆地;同样具备单井产量低,递减快 的特点 (11) 3.中美页岩气发展对比:产量具备增长潜力,但是开发难度较大 (12) 3.1.非常规气中页岩气未来增速最快 (12) 3.2.我国页岩气储量大,具备开采潜力分布广泛 (14) 3.3.我国与北美页岩气技术差距大、且可开采难度高、资源分布在人 口密集地区 (16) 3.3.1.钻井、压裂改造技术以及单井开发效果等方面依然与美国存 在较大差距 (17) 3.3.2.我国页岩气的主要产地可开采难度相对较高 (17) 3.3.3.我国页岩气分布在人口密集地区,水资源需要合理分配 . 18 3.4.美国页岩气产量2004年后快速发展 (19) 4.国家层面对页岩气产业的政策支持:开放市场、设置发展规划、完善补贴政策 (22) 4.1.开放市场、设定发展规划提升产量 (22) 4.2.将致密气纳入补贴范围,补贴“多增多补” (22) 5.北美页岩气产业资本开支趋向谨慎 (23) 6.结论:中国页岩气产业具备增产潜能,但恐难复制北美页岩气革命 27 7.风险提示 (29)

图 1 常规、非常规油气基本特征以及分布实例 (8) 图 2页岩气主要集中于中国的西南以及鄂尔多斯地区 (8) 图 3 简单井身结构示意图 (9) 图 4 射流分层压裂技术示意图 (9) 图 5煤层气生产井示意图 (9) 图 6 通过打页岩气储层水平井三步骤可获得更大泄流面积 (10) 图 7 水平井分段压裂泄流面积更大 (11) 图 8 水平井分段压裂减少对储层伤害 (11) 图 9非常规天然气2014、2015、2017年产量递增 (12) 图 10中国陆上页岩气田主要分布在蜀南地区 (14) 图 11 矿产勘查新增查明资源储量(亿立方米) (14) 图 12 矿产查明资源储量(亿立方米) (15) 图 13中国页岩气技术可采资源量占比高(万亿立方米) (15) 图 14长宁区块地层结构及小层储量评价技术图 (16) 图 15川南地区龙马溪组埋深3500~4500米评价井分布图 (16) 图 16中美页岩气典型剖面对比 (17) 图 17中美页岩气层在成藏过程、产期阶段、储层厚度、改造难度方面存在差异 (18) 图 18美国非常规气占比近60%,页岩气产量2004年后快速发展 .. 19 图 19美国页岩气产量逐年递增 (20) 图 20美国陆上页岩气田分布 (20) 图 21化工企业大量投资美国页岩油气公司 (21) 图 22 Permian新建与扩建管线计划持续更新 (22) 图 23 名义资本开支增加 (23) 图 24实际资本开支增加 (24) 图 25投资重点正转向传统油气开发项目 (24) 图26 2025-2030年能源投资较2018年将增加,天然气相关投资将增长 (25) 图 27页岩气公司资本开支低于市场预期(单位:百万美元) (25) 图 28页岩气公司现金流2019年Q1显著恶化 (26) 图 29页岩气公司2019年Q1产量低于预期 (26) 图 30 美国页岩油企业债务需要90亿桶石油偿还 (27) 图 31 北美页岩企业债务保持在高水平 (27) 图 32我国天然气消费量、产量、进口依赖度逐年攀升 (27) 图 33 一次能源消费按种类结构预测中可再生、天然气增幅大 (28) 图 34 中国工业终端能源消费增速持续下降 (28)

涪陵页岩气体积压裂改造理念及关键技术

涪陵页岩气体积压裂改造理念及关键技术 邹龙庆张剑李彦超 (川庆钻探井下作业公司) 摘要涪陵页岩储层为龙马溪组海相页岩,以灰黑色粉砂质页岩及灰黑色碳质页岩为主,优质页岩厚度为38m~44m,储层具有有机质类型好、丰度高、矿物脆性指数高、可压性强、裂缝层理发育、含气性高等特点。本文系统总结了涪陵页岩气体积压裂改造理念及关键特色技术,即以综合地质评价为改造基础,以大型体积压裂为储层改造理念,以水平井及多级压裂为技术保障,获取最大的储层改造体积,实现页岩气的高效开发。涪陵页岩气体积改造理念及关键技术为前期27口井的高效开发提供了技术保障,为未来中国海相页岩气高效开发积累了经验。 关键词页岩气涪陵体积改造水平井分段压裂 前言 四川盆地是我国页岩气最富集有利区,主要勘探区域为威远、长宁、富顺-永川、昭通、涪陵地区,层系为志留系龙马溪组、寒武系筇竹寺组,其中,涪陵区块位于川东高陡褶皱带万县复向斜的南扬起端包鸾一焦石坝背斜带焦石坝构造高部位,川东南涪陵地区评价下志留统龙马溪组。借鉴北美海相页岩气体积压裂改造经验,通过对涪陵区块页岩储层岩心资料、测井数据、岩石力学参数等资料综合分析,建立页岩储层综合可压指数预测模型,实现储层改造评价;借助页岩储层大型体积压裂改造理念,应用水平井及分段压裂技术,进行涪陵地区页岩气开发[1-4]。截至2014年5月17日,在涪陵页岩气田280平方公里一期产建区,已开钻页岩气井82口,完钻47口,投产27口,平均单井日产气量在11万方以上,涪陵页岩气体积改造理念及关键技术为前期27口投产井的高效开发提供了技术保障。 1. 储层地质特征 1.1气藏基本特征 涪陵页岩气区块主要目的层位为龙马溪组地层,埋藏深度为2400~3500m,优质页岩厚度为38m~42m,岩性为灰黑色粉砂质页岩及灰黑色碳质页岩,天然

北美地区典型页岩气盆地成藏条件解剖要点

北美地区典型页岩气盆地成藏条件解剖 1、阿巴拉契亚盆地俄亥俄页岩系统 (1)概况 阿巴拉契亚盆地(Appalachian)位于美国的东部,面积280000平方公里,包括New York西部、Pennsylvania、West Virginia、Ohio、Kentucky和Tennessee 州等,是美国发现页岩气最早的地方。俄亥俄(Ohio)页岩发育在阿巴拉契压盆地西部,分布在肯塔州东北部和俄亥俄州,是该盆地的主要页岩区(图2)。该区古生代沉积岩是个巨大的楔形体,总体上是富含有机质页岩、碎屑岩和碳酸盐岩构成的旋回沉积体。 图1 美国含页岩气盆地分布图 1953年,Hunter和Young对Ohio页岩气3400口井统计,只有6%的井具有较高自然产能(平均无阻流量为2.98万m2/d),主要原因是这些井的页岩中天然裂缝网络比较。其余94%的井平均产量为1726m3/d,经爆破或压裂改造后产量达8063m3/d,提高产量4倍多。1988年前,美国页岩气主要来自Ohio页岩气系统。截止1999年末,该盆地钻了多达21000口页岩井。年产量将近34亿m3。天然气资源量58332—566337亿m3,技术性可采收资源量4106~7787亿m3。每口井的成本$200000-$300000,完井成本$25~$50。 (2)构造及沉积特征 阿巴拉契亚盆地东临Appalachian山脉,西濒中部平原,构造上属于北美地台和阿巴拉契亚褶皱带间的山前坳陷。伴随Laurentian古陆经历了由被动边缘型

向前陆盆地的演化过程。盆地以前寒武纪结晶岩为基底,古生代沉积岩呈巨大的楔形体(最大厚度12 000 m)埋藏于不对称的、向东变深的前陆盆地中。寒武系和志留一密西西比系为碎屑岩夹碳酸盐岩,奥陶系为碳酸盐岩夹页岩,宾夕法尼亚系为碎屑岩夹石灰岩及煤层。总体上由富有机质泥页岩(主要为碳质页岩)、粉砂质页岩、粉砂岩、砂岩和碳酸盐岩等形成3~4个沉积旋回构成,每个旋回底部通常为富有机质页岩,上部为碳酸盐岩。泥盆系黑色页岩处于第3个旋回之中,分布于泥盆纪Acadian 造山运动下形成的碎屑岩楔形体内(James,2000)。该页岩层可再分成由碳质页岩和较粗粒碎屑岩互层组成的五个次级旋迥(Ettensohn ,1985)。它们是在阿卡德造山运动的动力作用下和Catskill 三角洲的向西进积中沉积下来的。 (3)页岩气成烃条件分析 ①页岩分布特征 阿巴拉契亚盆地中南部最老的泥盆纪 页岩层系属于晚泥盆世。Antrim 页岩和New Albany 大致为Chattanooga 页岩和Ohio 页 岩的横向同位层系(Matthews,1993)。在俄 亥俄东边和南边,Huron 段分岔。有的地区已 经被插入的灰色页岩和粉砂岩分成两个层。 俄亥俄页岩系统,覆盖于Java 组之上 (图3)。由三个岩性段组成:下部 Huron 段 为放射性黑色页岩,中部Three Lick 层为 灰色与黑色互层的薄单元,上部Cleveland 段为放射性黑色页岩。俄亥俄页岩矿物组成 包括:石英、粘土、白云岩、重金属矿(黄 铁矿)、有机物。 图2是西弗吉尼亚中部和西部产气区泥 盆纪页岩层的地层剖面。中上泥盆统的分布 面积约128,000mi 2(331,520km 2),它们沿 盆地边缘出露地表。页岩埋藏深度为610~ 1520m ,页岩厚度一般在100-400ft(30— 120m),泥盆系黑色页岩最大厚度在宾夕尼亚州的中北部(图3)(deWitt 等,1993)。 ②页岩地球化学特征 图4表示Ohio 页岩下Huron 段烃源岩有机碳等值线图。从镜质体反射率特征来图2 阿巴拉契亚盆地西部中泥盆统-下密西西比系剖面 (据Moody 等,1987)

期待中国的页岩气革命

期待中国的页岩气革命 2011-05-25 08:44:55 《财经》作者:陈卫东微博评论浏览次数:515 字号:T|T 过去100年石油工业最伟大的事件,莫过于21世纪头十年发生在美国的页岩气革命。 按照油气有机生成学说,生烃岩层中所产生的油气被排出、迁移,富集于有较高孔隙性、渗透性的岩层空间内,就形成常规油气藏。而没有被排出于生烃岩层中的油气,则属于非常规油气,其中保留于煤层中的气体称之为煤层气,保留于泥、页岩中的气体称之为页岩气,此外致密油、页岩油、油砂等油气资源也被列入非常规油气资源之内。 常规油气只占油气总资源的20%,但直到本世纪初,占总资源量80%的非常规油气才得以大规模开采。 石油工业新阶段 从上世纪80年代初,经过20年探索,页岩气终于有了商业性开发价值。 2006年美国页岩气产量为当年天然气总产量的1%,2010年这一数据跃升至17%,超过1000亿立方米(2010年中国天然气总产量为944.8亿立方米)。五年间,美国页岩气产量增长近20倍。在2009年2月的美国剑桥能源周上,专家们用“页岩气革命”来形容美国在页岩气领域取得的重大突破。 页岩气被束缚在致密的、几乎没有孔隙和裂缝的页岩(烃源岩)里,必须通过大规模地层压裂,在页岩里人工制造大量的长裂缝,并能把裂缝支撑住,形成气体的通道,让气体保持压力并源源不断地流入井筒,进入采集系统,最后进入集输管道,方能够成为商品。这其间的技术难度,让页岩气的开发利用一直可望而不可即。 进入本世纪,水平钻井技术和地层压裂技术日趋成熟,同时又发展了水平井分段压裂技术和多种技术的综合使用,美国石油工业终于能让页岩气挣脱大自然的束缚为人类所用。准确地讲,页岩气在商业上的成功不是勘探技术,而是开采技术的突破所致。 2010年6月,在阿姆斯特丹召开的“解放您的潜力——全球非常规天然气2010年会”上,一位90岁的老人、页岩气钻井和压裂技术的先驱——美国Mitchell Energy & Development 公司的乔治·米歇尔(George Mitchell)先生被授予美国天然气技术研究所终身成就奖。据报道,他创建的Mitchell公司花了17年时间,数以亿计的美元,先后钻了30多口试验井,测试了多种钻井和各种地层压裂的方法,以及压裂液支撑剂的组合,终于把束缚在页岩里的天然气大规模地、经济地开采了出来。 米歇尔先生的成功引发了美国的页岩气革命,几年时间内,美国一跃成为世界天然气第一大资源国和生产国,不但有望实现天然气的自给,还有可能成为天然气出口国,这一转变对世界天然气的供求格局产生了巨大的影响。

重庆涪陵焦石坝页岩气田勘探开发纪实

重庆涪陵焦石坝页岩气田勘探开发纪实 重庆涪陵焦石坝页岩气田勘探开发纪实 焦石坝,重庆涪陵区一个山区小镇。在这里,我国第一口实现规模化、商业化生产的页岩气井诞生,被命名为“页岩气开发功勋井”。今年3月24日,中国石化正式宣布,计划在2017年把涪陵页岩气田建成国内首个年产能100亿立方米的页岩气田,相当于一个1000万吨级大型油田。 重大突破 页岩气田进入商业开发 在中国石化勘探南方分公司岩芯库,保存着一筒采自焦页1HF井3000多米深处的深灰色页岩。“在焦石坝地底下,这些页岩就像一床大棉被,包裹着丰厚的页岩气。”分公司地质专家夏维书说。 撕开这床大棉被的“第一钻”在2012年2月14日晚8时开钻。11月28日,一个振奋人心的消息从焦石坝传来:焦页1HF井当天钻获20.3万方高产页岩气,这标志着我国第一口实现规模化、商业化生产的页岩气井诞生了。 页岩气是一种重要的非常规天然气,被认为是继常规天然气之后,又一种可以大规模开发的优质清洁能源。近年来,全球特别是北美地区,页岩气开发步伐明显加快。美国由于页岩气的大规模开采,甚至可能从油气输入国变为油气输出国。 在我国,常规天然气储量有限,而页岩气储量相对丰富。页岩气如果能得以大规模开发,对缓解我国天然气紧张局面、降低天然气对外依存度意义重大。 2011年,我国将页岩气列为独立矿种;2012年,出台《页岩气发展规划(2011—2015年)》;2013年,国家能源局正式批准涪陵页岩气田为国家级页岩气产能建设示范区。 继焦页1HF井后,环绕其周边数公里区域内,几口评价井也相继部署开采。2013年7月2日,焦页1—3HF井投产,测试产量20多万方/日;9月29日,焦页6—2HF 井投产,测试产量达35万方/日;10月9日,焦页8—2HF井投产,测试产量再创新高,达55万方/日。 “到这时,我们已吃上了定心丸:焦石坝区块页岩气藏不是一点,而是一片;这里不仅有页岩气,而且是高产气藏。”江汉油田涪陵工区项目部经理习传学说。 截至今年5月17日,在涪陵页岩气田280平方公里一期产建区,已开钻页岩气井82口,完钻47口,投产27口,平均单井日产气11万方以上。今年内,该区域将规划投产100口井左右。 “涪陵页岩气田进入商业开发,是我国页岩气开发的重大突破。”业内专家指出,我国页岩气资源潜力大、分布面积广、发育层系多,一旦形成产能,将对满足我国不断增长的能源需求、促进节能减排、优化能源结构、保障能源安全和促进经济社会发展具有重大战略意义。 技术创新 让

页岩气资源分布_开发现状及展望

第12卷第2期2010年4月 资源与产业 RESOU RCES &I NDU STR IES V ol 12N o 2 Apr 2010 收稿日期:2009-11-20;修订日期:2010-03-08;责任编辑:车遥。 基金项目:国家重点基础研究发展规划项目(2008ZX05000-014);长江学者和团队创新发展计划(I RT 0864)。 第一作者简介:安晓璇(1984 ),女,硕士生,主要从事碳酸盐岩储层评价研究。E m a i:l an2003xuan @yahoo co m cn 资源开发 页岩气资源分布、开发现状及展望 安晓璇1,黄文辉1,刘思宇1,江怀友2 (1 中国地质大学 海相储层演化与油气富集机理教育部重点实验室,北京100083; 2 中国石油经济技术研究院,北京 100011) 摘 要:目前页岩气资源勘探开发已成为世界焦点,研究表明世界页岩气的资源量为636 283 1012m 3。美国页岩气资源丰富,广泛分布于美国的南部、中部及东部。中国也拥有丰富的页岩气资源,据初步评价与美国页岩气资源量大体相当,但目前我国页岩气开发还处于初级阶段。美国是页岩气勘探开发技术最先进,开发最全面的国家,加拿大也有较长的页岩气开发历史。由于页岩气储层渗透率低,开采难度大,因此我们需要学习国外先进技术,开发一套适合我国页岩气储层的钻井开采工艺,同时需要国家的大力支持,推动我国页岩气产业的发展。 关键词:页岩气;页岩气资源量;开发现状;展望中图分类号: P618 13 文献标识码:A 文章编号:1673-2464(2010)02-0103-07 THE D ISTR IBUTI ON ,DEVELOP MENT AND EXPECTATION OF SHALE GAS RES OURCES AN X iao xuan 1 ,HUANG W en hui 1 ,LI U S i yu 1 ,JI A NG H ua i you 2 (1.T he Educa tionM i n istry K ey Laboratory of M arine Reservo i r E vo l ution and H ydro carbon A ccu mu l a tion M echan is m,Ch i na Universit y of G eosciences,B eijing 100083,China ; 2.Institute of Econo m ics and T echnology,C N PC,B eijing 100011,Ch i na) A bstrac t :The exp l o ra ti on o f shale gas resources becom es a focus of t he wor l d .T he natura l g as resources a re 636 283 1012m 3i n the wo rld Sha le gas resources are r i ch i n Ame rica ,m ost of t he m are distri buted i n southe rn ,cen tral and eastern parts T here also are p l enty o f shale gas resources i n Ch i na , nea rl y the same quantity as i n Ame rica In Am erica there is t he mo st advanced exp l o ration and expl o ita ti on techno l ogy ,and it i s t he on l y country wh ich has the h i ghest explo itati on m ethod Canada has a l ong h i story o f sha l e gas exp l o ration and expl o ita ti on Ch i na is still at the beg inn i ng for the s ha l e gas explo itati on The permeability of t he shale ro cks is nor m a lly very l ow,so it is difficu lt to be explo ited T herefore ,w e need to l ea rn the advanced foreign techno l ogy to deve l op a set o f exp l o itation m et hods t o dev elop our sha le gas reservo irs ,and w e need the suppo rt fro m t he gove rn m ent ,i ncreasing env iron m ental pro tecti on wh ile deve l op m ent K ey word s :sha l e gas ;sha l e gas resources ;exp l o itation m ethod ;explorati on expectation 1 页岩气概述 页岩气是指那些聚集在暗色泥页岩或高碳泥页 岩中,以吸附或游离状态为主要存在方式的天然 气 [1] 。在页岩气藏中,天然气不仅存在于泥页岩, 也存在于夹层状的粉砂岩、粉砂质泥岩、泥质粉砂岩和砂岩地层中。

四 中国页岩气选取及标准

中国页岩气前景评价 1.中国页岩气成藏条件分析及勘探方向 页岩气的勘探开发始于美国,自从1821年在美国纽约Chautauqua县的第一口工业性天然气钻井在泥盆系Dunkil’k页岩(8m深度时产出裂缝气)中发现页岩气,至今已经有180多年历史,尤其是20世纪80年代以来,由于认识到了页岩气吸附机理,美国页岩气的勘探开发得到了快速发展。2006年美国拥有超过39500口页岩气井,页岩气产量达到了7245×108ft3 (204×108m3),占美国总天然气产量的8%,页岩气总资源量估计在500~600×1012ft3范围内,是已投入工业性开发的三大非常规天然气类型(即致密砂岩气或称根缘气、煤层气、页岩气)之一,成为重要的天然气替代能源。近年来,加拿大、澳大利亚、俄罗斯等国也相继开展了页岩气的勘探和研究工作,但目前,除了美国以外还没有见到有关页岩气商业化开采的报道(T.Ahlbrandt,2001),其原因要么是对页岩气的资源潜力和经济价值的认识不足,要么是页岩气井的产量和回收期未达到商业化标准,而不是缺乏潜在的产气泥页岩系统。随着世界能源消费量的猛增和供需矛盾的日益突出,非常规天然气资源引起了普遍重视,不少国家将页岩气、煤层气、油砂、油页岩等非常规油气资源的勘探开发提上了重要议事日程,将其列为2l世纪重要的补充能源,加大了勘探开发和综合利用力度。 自20世纪60年代以来,在中国东部的油气勘探中,陆续发现了一些泥页岩裂缝型油气藏(如四川盆地下古生界、沁水盆地上古生界泥页岩在钻井过程中气测异常强烈,甚至发生井喷),只是作为常规油气勘探中的一些局部发现,并未引起足够的重视,研究不够深入,没有认识页岩气的吸附机理,页岩气的勘探开发没有实现突破。近年来,中国一些学者受美国页岩气成功开发的启示,加强了页岩气的形成条件和成藏机理研究,但是针对页岩气的勘探工作还未展开。目前,中国石油、中国石化针对页岩气相继开展了一些区域性、局部性的基础研究工作,取得了一些的研究成果,初步展示了中国页岩气勘探巨大的资源潜力。页岩气是目前经济技术条件下,天然气工业化勘探的重要领域和目标,页岩气勘探一旦突破并形成产能,将对缓解中国油气资源接替的压力具有重大而深远的意义。 一、页岩气藏特征及成藏机理 页岩气,以及煤层气、致密砂岩气、溶解气、天然气水合物通称为非常规天然气资源,与常规天然气相比,页岩气在成藏条件及成藏机理等方面既有相似之处,又有不同点。John B.unis认为页岩气系统基本上是生物成因、热成因或者二者混合成因的连续型天然气聚集,页岩气可以是储存在泥页岩天然裂隙和粒间孔隙内的游离气,也可以是干酪根和页岩黏土颗粒表面的吸附气或是干酪根和沥青中的溶解气。中国学者张金川等(2004)认为页岩气是指主体位于暗色泥页岩或高碳泥页岩中,以吸附或游离状态为主要存在方式的天然气聚集,为天然气生成之后在源岩层内就近聚集的结果,表现为典型的“原地”成藏模式。从某种意义来说,页岩气藏的形成是天然气在烃源岩中大规模滞留的结果。我们通过对国内外关于页岩气形成及聚集方式描述的分析,从成因、赋存机理两方面说明页岩气的概念、含义。页岩气是由泥页岩(作为烃源岩)连续生成的生物化学成因气、热成因气或两者的混合,在页岩系统(作为储集岩)中以吸附、游离或溶解方式赋存的天然气。页岩系统包括:页岩及页岩中呈夹层状的粉砂岩、粉砂质泥岩、泥质粉砂岩,甚至砂岩。 页岩气藏的特征体现在生成、运移、赋存、聚集、保存等方面:(1)早期成藏。页岩气的生烃条件及过程与常规天然气藏相同,泥页岩的有机质丰度、有机质类型和热演化特征决定了其生烃能力和时间,但是页岩气边形成边赋存聚集,不需要构造背景,为隐蔽圈闭气藏; (2)自生自储,泥页岩既是气源岩层,又是储气层,页岩气以多种方式赋存,使得泥页岩具有普遍的含气性;(3)页岩气运移距离较短,具有“原地”成藏特征;(4)对盖层条件要求没有

国外页岩气勘探开发综述

第13卷第2期重庆科技学院学报(自然科学版)2011年4月 收稿日期:2010-11-29 基金项目:国家重大专项(2008ZX05022-005) 作者简介:胡进科(1985-),男,四川合江人,西南石油大学在读硕士研究生,研究方向为页岩气储层保护理论与技术、欠平衡钻 完井。 页岩是一种渗透率极低的沉积岩,通常被认为是油气运移的天然遮挡。在含气油页岩中,天然气产自其中,页岩既是气源岩,又是储层。天然气可以储存在页岩岩石颗粒之间的孔隙空间或裂缝中,也可以吸附在页岩中有机物的表面上。我国页岩气勘探开发起步较晚,尚有待进一步发展完善。美国是世界上勘探开发页岩气最成功的国家。在此我们对国外页岩气勘探开发现状进行分析,以资借鉴。 1资源量概况 从全球范围来看,页岩气拥有巨大的资源量。 据统计,全世界的页岩气资源量约为456.24× 1012m 3,相当于致密砂岩气和煤层气资源量的总 和,具有很大的开发潜力,是一种非常重要的非常规资源[1]。页岩气资源量占3种非常规天然气(煤层气、致密砂岩气、页岩气)总资源量的50%左右,主要分布在北美、中亚和中国、中东和北非、拉丁美洲、前苏联等地区,与常规天然气相当。页岩气的资源潜力甚至还可能明显大于常规天然气。世界各地区非常规天然气分布和资源量情况如表1和图1所示,图1中1tcf=2.8317×1010m 3。 2 勘探开发情况 2.1 勘探 勘探方面主要采用地震勘探技术。高分辨率三 维地震技术有助于准确认识复杂构造、储层非均质 国外页岩气勘探开发综述 胡进科 李 皋1 陈文可2 姚 远3 蒋延娜4 (1.西南石油大学油气藏地质及开发工程国家重点实验室,成都610500; 2.中石化江苏油田钻井处泥浆公司,扬州225263; 3.中石化胜利油田钻井泥浆公司,东营257064; 4.中石化西南石油局地质录井公司,绵阳621605) 摘要:美国是世界上勘探开发页岩气最成功的国家,主要采用水平井+水力压裂进行开发。调研表明,页岩气资源 量约占全球非常规天然气资源量的一半。国外页岩气勘探主要采用三维地震和微地震技术优化设计,已形成一套资源评价系统。国外钻井选择直井和水平井两种方式。完井储层改造多采用裸眼、筛管等完井方式,配合大型水力压裂改善页岩的超低渗透率。 关键词:页岩气;钻井;完井;储层改造中图分类号:TE132 文献标识码:A 文章编号:1673-1980(2011)02-0072-04表1 世界各地区非常规天然气资源量分布情况 m 3 地区页岩气 煤层气致密砂岩气合计 北 美 108.7×10 12 85.4×10 12 38.8×1012 232.9×1012拉丁美洲59.9×1012 1.1×101236.6×101297.6×1012中欧+西欧15.5×10127.7×101212.2×101235.4×1012前苏联17.7×1012112.0×101225.5×1012155.2×1012中东+非洲79.9×1012 1.1×101245.5×1012126.5×1012中亚+中国99.8×101234.4×101210.0×1012144.2×1012太平洋地区65.5×101213.3×101220.0×101298.8×1012其他亚太地区8.9×1012 1.1×101221.0×101231.0×1012全世界456.0×1012256.1×1012 209.6×1012 921.7×10 12 图1 页岩气全球资源分布情况

647.2-2013_页岩气水平井钻井作业技术规范_第_2_部分:钻井作业(出版稿)

Q/SYCQZ 川庆钻探工程有限公司企业标准 Q/SYCQZ 647.2—2013 页岩气水平井钻井作业技术规范 第2部分:钻井作业 2013-12-22发布2014-01-22实施

目次 前言................................................................................. II 1 范围 (1) 2 规范性引用文件 (1) 3 钻井工程设计 (1) 4 井眼轨迹控制 (2) 5 防碰作业 (3) 6 水平段安全钻井 (3)

前言 《页岩气水平井钻井作业技术规范》分为五个部分: ——第 1 部分:丛式井组井场布置; ——第 2 部分:钻井作业; ——第 3 部分:油基钻井液; ——第 4 部分:水平段油基钻井液固井; ——第 5 部分:井控。 本部分为第 2 部分。 本标准按 GB/T 1.1-2009《标准化工作导则第 1 部分:标准的结构和编写规则》进行编写和表述。 本标准由川庆钻探工程有限公司提出。 本标准由川庆钻探工程有限公司钻井专业标准化技术委员会归口。 本标准起草单位:川庆钻探工程有限公司钻采工程技术研究院、川庆钻探工程有限公司川东钻探公司、川庆钻探工程有限公司川西钻探公司 本标准主要起草人:张德军、赵晗、卓云、叶长文。

页岩气水平井钻井作业技术规范第2部分:钻井作业 1 范围 本标准规定了页岩气丛式井组钻井工程设计、井眼轨迹控制、防碰作业、水平段安全钻井等内容和要求。 本标准适用于川渝地区页岩气井的钻井作业。 2 规范性引用文件 下列文件对于本文件的应用是必不可少的。凡是注日期的引用文件,仅所注日期的版本适用于本文件。凡是不注日期的引用文件,其最新版本(包括所有的修改单)适用于本文件。 SY/T 1296 密集丛式井上部井段防碰设计与施工技术规范 SY/T 5088-2008 钻井井身质量控制规范 SY/T 5416 定向井测量仪器测量及检验 SY/T 5435-2003 定向井井眼轨迹设计与轨迹计算 SY/T 5547 螺杆钻具使用、维修和管理 SY/T 5619 定向井下部钻具组合设计方法 SY/T 6332-2004 定向井轨迹控制 SY/T 6396 钻井井眼防碰技术要求 Q/SYCQZ 001 钻井技术操作规程 Q/SYCQZ 372-2011 丛式井井眼防碰技术规程 3 钻井工程设计 3.1 井身结构 3.1.1 表层套管应封隔地表漏层和垮塌层,相邻两井表层套管下深错开20 m以上。 3.1.2 水平井技术套管下入位置井斜应不低于60°,若井下出现严重垮塌、钻遇高压油气,可提前下入技术套管。 3.1.3 油层套管尺寸不小于 11 4.3 mm,抗内压强度与增产改造施工压力之比>1.25。 3.1.4 水平段长度宜控制在800 m ~ 1400 m。 3.2 靶区 3.2.1 靶区半径设计符合SY/T 5088-2008的规定,且满足井眼轨迹控制要求。 3.2.2 水平段井眼方向与地层最小主应力方向的夹角不小于 15°。 3.3 井眼轨道 3.3.1 每口井地下靶心与井口位置连线相互之间不宜空间交叉。

涪陵页岩气概况

涪陵页岩气田开发中的地球物理面临的问题 1、概况 涪陵地区地处四川盆地和盆边山地过渡地带,境内地势以低山丘陵为主,横跨长江南北、纵贯乌江东西两岸,海拔多在200~800m之间,涪陵地区所处的四川盆地是在一个特提斯构造域内长期发育、不断演进的古生代-中新生代海陆相复杂叠合的盆地,具有早期沉降、晚期隆升、沉降期长、隆升期短等特点。该地区经历了加里东、海西、印支、燕山和喜山多期构造运动,多期构造运动的叠加改造形成了现今的构造格局。 涪陵页岩气资源富集,分布面积约7.6万平方公里,地质资源量约12.8万亿立方米,可采资源量约2万亿立方米,列全国第3位。涪陵区拥有典型的优质海相页岩气,主要含气页岩层段为奥陶系五峰组-志留系龙马溪组,截止2105年已上交探明储量3806亿立方米,是全国首个千亿方级整装页岩气田。江汉油田在涪陵焦石坝区块开展的页岩气开发和产建工作,标志着中国石化非常规天然气勘探开发进入新阶段。涪陵页岩气田根据开发阶段,分为I期产建区和II产建区,I期产建区焦石坝构造主体区,为断背斜构造,地震资料品质好,构造完整、断裂不发育,页岩气保存条件好,2015年实现产能50亿方。从开发效果来看一期产建区页岩品质差别不大,但含气量存在明显的分区性,北部构造高部位含气量高,单井平均测试产量超过50万方,南部斜坡、乌江背斜带、东部及西部断裂发育区,含气量明显降低,单井平均测试产量低于10万方。构造类型、埋深、断裂发育程度、裂缝、地应力以及地层压力不仅造成了含气性的差异,同时影响了压裂改造效果。 II期产建区包含一起产建外围区以及焦石坝南三维区,通过初步评价优选了江东、平桥、白涛、白马、梓里场等五个区块为优先钻探区域,其中江东、及平桥区块完成了部署,目前评建工作已全面展开。二期产建区地震资料品质普遍低于一期,构造条件复杂、断裂及发育,地应力非均质性强,埋深相对增大,页岩品质及含气性都差于一期主体区。 目前,涪陵页岩气田投产井232口,日产气水平达到1136.8019

美国页岩油发展现状及预期

美国页岩油发展现状及预期 摘要美国的页岩气开发取得了巨大成就,天然气价格急剧下降,然而原油价格却居高不下,于是石油公司在不放弃页岩气的同时,将开发重点转向页岩油。美国原油进口量大幅下降,炼油业迅速复苏,给经济恢复带来动力,对世界石油地缘政治格局产生重大影响。虽然目前国际油价大幅下跌造成了页岩油开发的停滞,但长远来看,页岩油开发在美国势在必行。 关键词美国页岩油影响因素发展 前言 古代人类就发现了石油和天然气。到19世纪中叶,美国和俄罗斯相继钻成了第一口油井,对油气需求的快速增加,促使对油气的开发从优质油气扩展到品质较差、开采难度较大和开采成本较高的油气(童晓光等,2014)。1979年,美国地质学家Masters 提出了油气资源分布的三角图概念(Masters,1979;Holditch,2006),三角图的顶部为常规油气,开采技术难度较低和开采成本较低,油的品质好,占总油气资源量的比例较小。非常规油气开采技术难度较大,开采成本较高,油的品质较差,但占油气总资源量中的比例大(童晓光等,2014;图1),其中页岩油的勘探和开发已经越来越受世界各国的重视。 页岩油是指储存于富有机质、纳米级孔径为主页岩地层中的石油,是成熟有机质页岩石油的简称(邹才能等,2013)。页岩既是石油的烃源岩,又是石油的储集岩。页岩油以吸附态和游离态形式存在,一般油质较轻、黏度较低。主要储集于纳米级孔喉和裂缝系统中,多沿片状层理面或与其平行的微裂缝分布。富有机质页岩一般在盆地中心大面积连续聚集,整体普遍含油,资源规模大。页岩油“核心区”评价的关键包括储集空间分布、储集层脆性指数、页岩油黏度、地层能量和富有机质页岩规模等。页岩气的成功开采为页岩油开采提供了技术参考,水平井体积压裂、重复压裂等“人造渗透率”改 图1 油气资源类型分布 造技术,是实现页岩油有效开发的关键技术(邹才能等,2013)。

中国页岩气研究现状与发展趋势

第31卷 第4期2010年7月 石油学报 A CT A PETROLEI SINICA V o l.31July N o.4 2010 基金项目:国家自然科学基金项目(No.40730422)资助。 作者简介:陈尚斌,男,1983年3月生,2009年获中国矿业大学硕士学位,现为中国矿业大学在读博士研究生,主要从事煤层气与页岩气地质的学习 和研究工作。E mail:shangbin chen @https://www.sodocs.net/doc/2816073937.html, 文章编号:0253 2697(2010)04 0689 06 综 述 中国页岩气研究现状与发展趋势 陈尚斌1,2 朱炎铭1,2 王红岩3 刘洪林3 魏 伟3 罗 跃1,2 李 伍1,2 方俊华1,2 (1 中国矿业大学煤层气资源与成藏过程教育部重点实验室 江苏徐州 221116; 2 中国矿业大学资源与地球科学学院 江苏徐州 221008; 3 中国石油勘探开发研究院廊坊分院 河北廊坊 065007) 摘要:借助维普中文科技期刊全文数据库,系统检索了中国页岩气的研究论文,分析了这百余篇论文的分布特征,归纳了研究机 构、科研群体及基金资助等情况,综述了中国页岩气研究现状,探讨了未来其研究的走向和发展需求。研究结果表明: 中国页岩气论文总数少,具有典型发展初期阶段分布特征,说明基础研究与勘探开发刚驶入一个全新的起步发展阶段,在未来一个较长时期,页岩气资源评价理论与方法将是研究的主要方向,地质基础研究工作必受重视,勘探试井及与之相关的产能模拟、压裂等增产开发措施研究也会逐步展开; 基于地质条件、成藏要素及油气产区特殊条件的综合分析,四川盆地南部地区很可能会成为中国第一个页岩气勘探开发的先导性试验建设基地;!在政策扶植和基金支持下,坚持科技攻关,开展多种合作,增进学术交流,促进人才培养,中国页岩气研究将迅速发展,并会较早结束探索阶段而逐步向商业化方向发展。 关键词:页岩气;论文分布特征;研究现状;发展趋势;综述;维普中文科技期刊全文数据库;中国中图分类号:T E 122 2 文献标识码:A Research status and trends of shale gas in China CH EN Shangbin 1,2 ZH U Yanm ing 1,2 WANG H ongyan 3 LIU H onglin 3 WEI Wei 3 LUO Yue 1,2 LI Wu 1,2 FANG Junhua 1,2 (1.K ey L abor ator y of Coalbed Methane Resour ces and Reser voir For mation Pr oces s of the M inistr y of Ed ucation , China Univers ity of M ining and T echnolo gy ,X uz hou 221116,China; 2.Schoo l of Resour ces and E ar th Science ,China Univer sity of M ining and T echnology ,X uz hou,221008,China; 3.L angf ang Br anch,Petr oChina Ex p lor ation and D evelop ment Resear ch I nstitute ,L ang f ang 065007,China) Abstract :W ith the aid of VI P Chinese sci tech periodical full text dat abase,the present paper systematically searched for the research papers on shale gas in Chinese,analyzed the distributio n char acter istics of these ov er o ne hundred paper s,summarized the research units,research gr oups and fo undation sponso rships,etc.involved in shale g as researches,r eview ed the cur rent status of shale g as researches in China,and pr obed into the tr end and develo pment necessity of shale g as researches in the futur e.T he r esults sho wed that firstly,shale g as paper s in Chinese ar e character ized by a limited number and a typical distributio n of the initial r esear ch,indica t ing an infancy for both the basic research and the explo ration and develo pment.W ithin a longer per iod of time in the fut ur e,the as sessment theor y and met ho ds on shale gas resour ces w ill be the focus of the research,basic r esear ches on geo log ical analyses w ill be highlighted,and studies on the prospect ing well testing and t he related pro duction and development measures including capacity sim ulat ion and fr act ur ing w ill be gr adually put o n the agenda as well.Secondly ,comprehensiv e analyses o f geolog ical conditio ns,reser v oir elements and specific conditio ns o f oil gas pro vinces indicated that the so uthern r eg io n o f the Sichuan Basin is mor e likely t o be the first pioneering ex per imental area fo r shale g as explorat ion and development in China.T hirdly ,the shale gas r esear ch in China will develop rapidly ,end the explor ing stag e soo n and trend to the co mmercial develo pment pr og ressively prov ided that the po licy fostering and fund suppor t ar e ava ilable,key problems in scientific and technolog ical researches are solved via persistent effo rts,var i eties o f co operation are ex panded,academic exchang es are enhanced and personnel tr aining is pr omoted. Key words :shale gas;paper distr ibut ion char acter istics;r esear ch status;developing trend;rev iew;VIP China sci tech per iodical full tex t database;China 随着油气资源的日趋紧缺和对于能源安全的考虑,页岩气这一新能源已成为世界能源研究的热点 之一,而中国的页岩气研究与勘探开发尚处于探索起步阶段 [1 2] 。一个领域内论文的分布蕴含着丰富

相关文档

- 涪陵焦石坝区块页岩气井动态合理配产技术

- 江汉涪陵页岩气压裂技术概述

- 中石化涪陵页岩气勘探开发经验一览

- 江汉涪陵页岩气压裂技术

- 涪陵大安寨页岩气涪页6-2HF井汇报

- 重庆涪陵焦石坝页岩气田勘探开发纪实

- 重庆涪陵页岩气后续产业开发情况

- 涪陵页岩气钻井工程安全风险分析与评估

- 重庆涪陵页岩气开发区域环境保护现状、问题 及对策

- 重庆涪陵焦石坝页岩气田勘探开发纪实

- 涪陵页岩气体积压裂改造理念及关键技术

- 重庆涪陵焦石坝页岩气田勘探开发纪实

- 四川盆地涪陵页岩气田

- 涪陵页岩气概况

- 重庆涪陵页岩气田勘探开发纪实

- 涪陵页岩气田井漏现状与技术对策

- 涪陵地区页岩气山地“井工厂”钻井技术

- 涪陵地区页岩气山地“井工厂”钻井技术