Power Control Algorithm for Hybrid Excavator With Supercapacitor

Power Control Algorithm for Hybrid Excavator With Supercapacitor

Tae-Suk Kwon,Member,IEEE,Seon-Woo Lee,Seung-Ki Sul,Fellow,IEEE,Cheol-Gyu Park, Nag-In Kim,Member,IEEE,Byung-il Kang,and Min-seok Hong

Abstract—This paper shows several structures of the hybrid excavator with the supercapacitor and compares them with each other from the aspect of fuel ef?ciency,the additional cost due to the hybridization,and the expected payback time.According to the comparison result,it can be concluded that a compound-type hybrid structure is a better solution than others because of its short expected payback time and higher reliability.In addition, the power control algorithm of the engine and the supercapacitor is proposed.To verify the proposed algorithm,the computer simu-lation and the engine dynamo test were performed,and the results are presented.The results show that the proposed control algo-rithm can achieve balance of the power and the energy between the energy sources and the load,and by hybridization,the fuel consumption can be reduced by about24%compared with the conventional hydraulic excavator.The hardware implementation is now in progress for a22-ton class excavator.

Index Terms—Hybrid excavator,power control,supercapacitor.

I.I NTRODUCTION

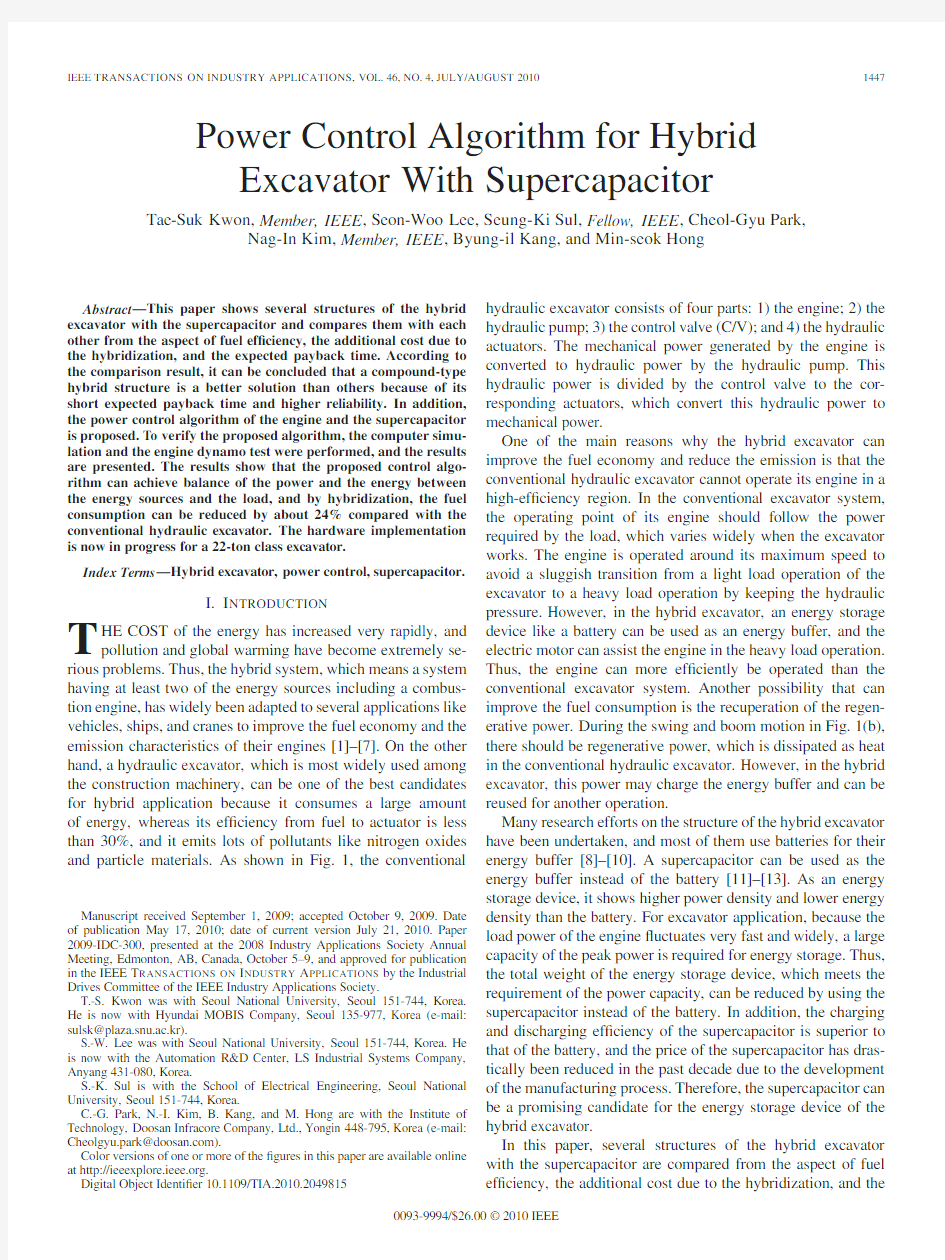

T HE COST of the energy has increased very rapidly,and pollution and global warming have become extremely se-rious problems.Thus,the hybrid system,which means a system having at least two of the energy sources including a combus-tion engine,has widely been adapted to several applications like vehicles,ships,and cranes to improve the fuel economy and the emission characteristics of their engines[1]–[7].On the other hand,a hydraulic excavator,which is most widely used among the construction machinery,can be one of the best candidates for hybrid application because it consumes a large amount of energy,whereas its ef?ciency from fuel to actuator is less than30%,and it emits lots of pollutants like nitrogen oxides and particle materials.As shown in Fig.1,the conventional

Manuscript received September1,2009;accepted October9,2009.Date of publication May17,2010;date of current version July21,2010.Paper 2009-IDC-300,presented at the2008Industry Applications Society Annual Meeting,Edmonton,AB,Canada,October5–9,and approved for publication in the IEEE T RANSACTIONS ON I NDUSTRY A PPLICATIONS by the Industrial Drives Committee of the IEEE Industry Applications Society.

T.-S.Kwon was with Seoul National University,Seoul151-744,Korea. He is now with Hyundai MOBIS Company,Seoul135-977,Korea(e-mail: sulsk@plaza.snu.ac.kr).

S.-W.Lee was with Seoul National University,Seoul151-744,Korea.He is now with the Automation R&D Center,LS Industrial Systems Company, Anyang431-080,Korea.

S.-K.Sul is with the School of Electrical Engineering,Seoul National University,Seoul151-744,Korea.

C.-G.Park,N.-I.Kim,B.Kang,and M.Hong are with the Institute of Technology,Doosan Infracore Company,Ltd.,Yongin448-795,Korea(e-mail: Cheolgyu.park@https://www.sodocs.net/doc/4c14173385.html,).

Color versions of one or more of the?gures in this paper are available online at https://www.sodocs.net/doc/4c14173385.html,.

Digital Object Identi?er10.1109/TIA.2010.2049815hydraulic excavator consists of four parts:1)the engine;2)the hydraulic pump;3)the control valve(C/V);and4)the hydraulic actuators.The mechanical power generated by the engine is converted to hydraulic power by the hydraulic pump.This hydraulic power is divided by the control valve to the cor-responding actuators,which convert this hydraulic power to mechanical power.

One of the main reasons why the hybrid excavator can improve the fuel economy and reduce the emission is that the conventional hydraulic excavator cannot operate its engine in a high-ef?ciency region.In the conventional excavator system, the operating point of its engine should follow the power required by the load,which varies widely when the excavator works.The engine is operated around its maximum speed to avoid a sluggish transition from a light load operation of the excavator to a heavy load operation by keeping the hydraulic pressure.However,in the hybrid excavator,an energy storage device like a battery can be used as an energy buffer,and the electric motor can assist the engine in the heavy load operation. Thus,the engine can more ef?ciently be operated than the conventional excavator system.Another possibility that can improve the fuel consumption is the recuperation of the regen-erative power.During the swing and boom motion in Fig.1(b), there should be regenerative power,which is dissipated as heat in the conventional hydraulic excavator.However,in the hybrid excavator,this power may charge the energy buffer and can be reused for another operation.

Many research efforts on the structure of the hybrid excavator have been undertaken,and most of them use batteries for their energy buffer[8]–[10].A supercapacitor can be used as the energy buffer instead of the battery[11]–[13].As an energy storage device,it shows higher power density and lower energy density than the battery.For excavator application,because the load power of the engine?uctuates very fast and widely,a large capacity of the peak power is required for energy storage.Thus, the total weight of the energy storage device,which meets the requirement of the power capacity,can be reduced by using the supercapacitor instead of the battery.In addition,the charging and discharging ef?ciency of the supercapacitor is superior to that of the battery,and the price of the supercapacitor has dras-tically been reduced in the past decade due to the development of the manufacturing process.Therefore,the supercapacitor can be a promising candidate for the energy storage device of the hybrid excavator.

In this paper,several structures of the hybrid excavator with the supercapacitor are compared from the aspect of fuel ef?ciency,the additional cost due to the hybridization,and the

0093-9994/$26.00?2010IEEE

Fig.1.(a)Structure and(b)operation of a conventionally hydraulic excavator.

expected payback time.According to the comparison result,the authors conclude that a compound-type hybrid structure is a better solution than others because of its short expected payback time and reliability.In addition,the power control algorithm of the engine and the supercapacitor is proposed.To verify the proposed algorithm,computer simulation was performed,and the results are presented.The hardware implementation is now in progress for a22-ton class excavator.

II.S TRUCTURES OF THE H YBRID

E XCAVATOR AND C OMPARISON

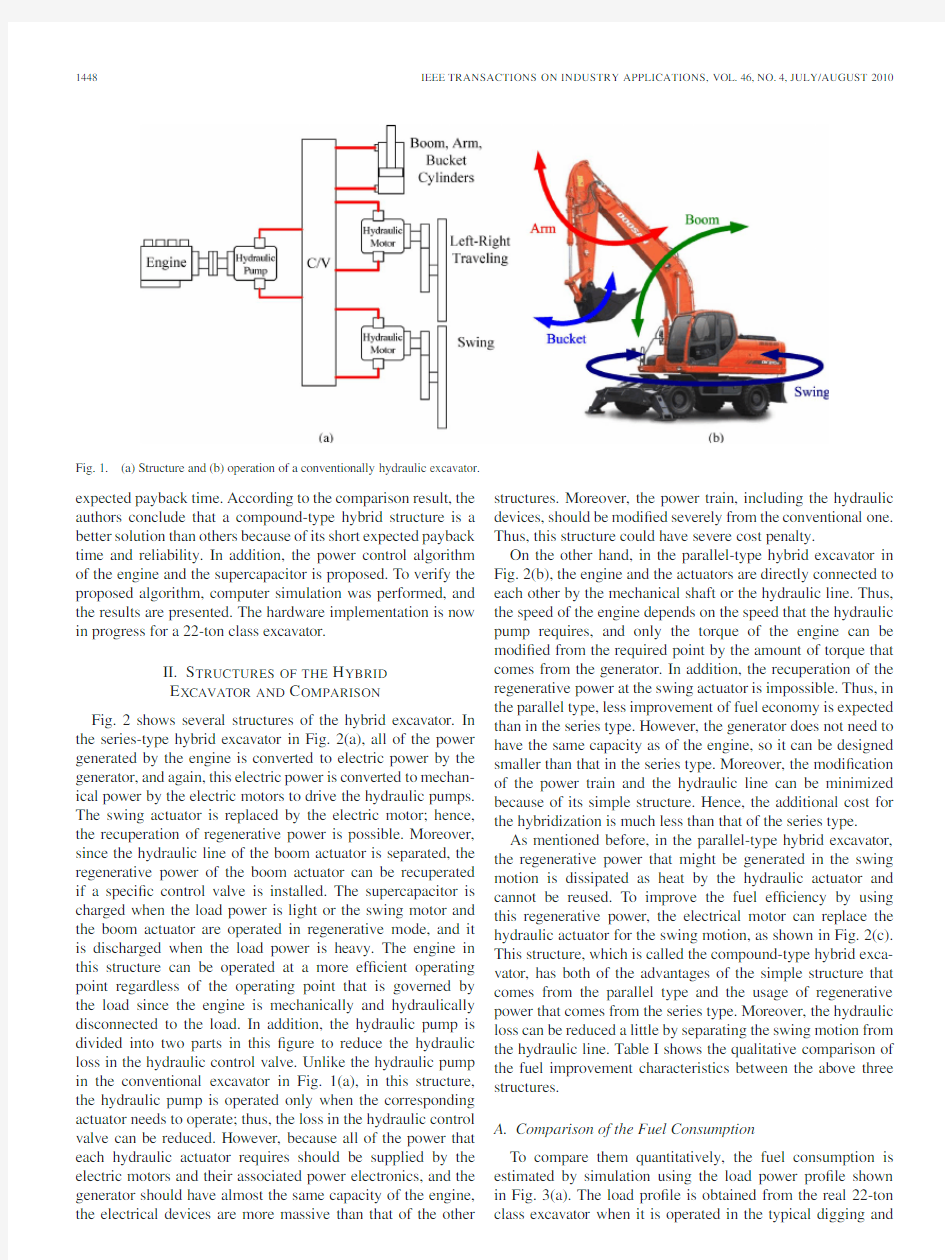

Fig.2shows several structures of the hybrid excavator.In the series-type hybrid excavator in Fig.2(a),all of the power generated by the engine is converted to electric power by the generator,and again,this electric power is converted to mechan-ical power by the electric motors to drive the hydraulic pumps. The swing actuator is replaced by the electric motor;hence, the recuperation of regenerative power is possible.Moreover, since the hydraulic line of the boom actuator is separated,the regenerative power of the boom actuator can be recuperated if a speci?c control valve is installed.The supercapacitor is charged when the load power is light or the swing motor and the boom actuator are operated in regenerative mode,and it is discharged when the load power is heavy.The engine in this structure can be operated at a more ef?cient operating point regardless of the operating point that is governed by the load since the engine is mechanically and hydraulically disconnected to the load.In addition,the hydraulic pump is divided into two parts in this?gure to reduce the hydraulic loss in the hydraulic control valve.Unlike the hydraulic pump in the conventional excavator in Fig.1(a),in this structure, the hydraulic pump is operated only when the corresponding actuator needs to operate;thus,the loss in the hydraulic control valve can be reduced.However,because all of the power that each hydraulic actuator requires should be supplied by the electric motors and their associated power electronics,and the generator should have almost the same capacity of the engine, the electrical devices are more massive than that of the other structures.Moreover,the power train,including the hydraulic devices,should be modi?ed severely from the conventional one. Thus,this structure could have severe cost penalty.

On the other hand,in the parallel-type hybrid excavator in Fig.2(b),the engine and the actuators are directly connected to each other by the mechanical shaft or the hydraulic line.Thus, the speed of the engine depends on the speed that the hydraulic pump requires,and only the torque of the engine can be modi?ed from the required point by the amount of torque that comes from the generator.In addition,the recuperation of the regenerative power at the swing actuator is impossible.Thus,in the parallel type,less improvement of fuel economy is expected than in the series type.However,the generator does not need to have the same capacity as of the engine,so it can be designed smaller than that in the series type.Moreover,the modi?cation of the power train and the hydraulic line can be minimized because of its simple structure.Hence,the additional cost for the hybridization is much less than that of the series type.

As mentioned before,in the parallel-type hybrid excavator, the regenerative power that might be generated in the swing motion is dissipated as heat by the hydraulic actuator and cannot be reused.To improve the fuel ef?ciency by using this regenerative power,the electrical motor can replace the hydraulic actuator for the swing motion,as shown in Fig.2(c). This structure,which is called the compound-type hybrid exca-vator,has both of the advantages of the simple structure that comes from the parallel type and the usage of regenerative power that comes from the series type.Moreover,the hydraulic loss can be reduced a little by separating the swing motion from the hydraulic line.Table I shows the qualitative comparison of the fuel improvement characteristics between the above three structures.

https://www.sodocs.net/doc/4c14173385.html,parison of the Fuel Consumption

To compare them quantitatively,the fuel consumption is estimated by simulation using the load power pro?le shown in Fig.3(a).The load pro?le is obtained from the real22-ton class excavator when it is operated in the typical digging and

KWON et al.:POWER CONTROL ALGORITHM FOR HYBRID EXCAVATOR WITH SUPERCAPACITOR

1449

Fig.2.Structures of the hybrid excavator.(a)Series type.(b)Parallel type.(c)Compound type.

TABLE I

C OMPARISON OF F UEL I

MPROVEMENT

Fig.3.(a)Sum of the actuator power and (b)engine power pro?le of the conventional excavator.

swing operation,so it consists of several cycles,including the series of various motions,for example,swing–boom–arm–bucket–arm–boom–swing–bucket,etc.Fig.3(b)shows the ac-tual output power of the conventional hydraulic excavator with the load power pro?le in Fig.3(a).All the values in Fig.3are normalized by the rated engine power.In the simulation,the following assumptions are employed.

1)The ef?ciencies of the motors,the generators,the super-capacitor,and their power electronic devices are all 95%.2)The ef?ciency of the gear box is 90%.

3)The ef?ciencies of the hydraulic pumps and the control valves are 85%and 70%,respectively.

4)The speci?c fuel consumption map is used for considera-tion of the engine ef?ciency.

5)The fuel cost is 1.5USD per liter.

Fig.4shows the simulated engine power of each hybrid structure under the above assumptions.It can be known that the amount of engine power is getting reduced for the same load power pro?le from top to bottom,that is,from the parallel to the series type.The difference of the engine power between the conventional excavator and the hybrid ones corresponds to the supercapacitor power.If this difference is positive,then the surplus power is charged at the supercapacitor,and if the difference is negative,then the shortage is supplied from the supercapacitor.In the parallel-type hybrid system,any regener-ative energy cannot be recuperated;thus,the amount of reduced engine power is not much.However,in the compound-type system,the regenerative power from the swing motion can be recovered,so the engine power can be reduced more than in the parallel type.In the series type,the regenerative power from the boom motion can also be recuperated,and the hydraulic loss of the control valve can be reduced;thus,the amount of reduced engine power is the largest.

Fig.5shows the comparison result of the fuel consumption with the load power pro?le shown in Fig.3.All of the value is normalized with the fuel consumption of the conventional excavator.As expected,the series-type hybrid system shows

1450IEEE TRANSACTIONS ON INDUSTRY APPLICATIONS,VOL.46,NO.4,JULY/AUGUST

2010

Fig.4.Engine power pro?le of (a)the parallel-type,(b)the compound-type,and (c)the series-type hybrid

excavator.

https://www.sodocs.net/doc/4c14173385.html,parison of the fuel consumption with respect to that of the conventional excavator.

the lowest fuel consumption,which is about 45%of the fuel consumption of the conventional https://www.sodocs.net/doc/4c14173385.html,parison of the Additional Cost

According to the analysis from the previous chapter,the series-type hybrid excavator is the most promising solution from the aspect of fuel ef?ciency.However,for the series-type hybrid excavator,a high cost should be paid for the hybridiza-tion.The capacity of the generator and its power converter should be large enough to cover the whole power range of the engine since all of the mechanical power should be converted to electrical power.In addition,a relatively large number of the motors and their power converter are required because to reduce the loss of the hydraulic line,each actuator should have its own hydraulic pump and control valve.Moreover,to achieve this loss reduction,the design of the hydraulic system is drastically changed,and additional hydraulic units are needed.To recover all of the regenerative power,the capacity of the supercapacitor should also be larger than that of the other structures.

On the other hand,for the parallel-type hybrid excavator,the capacity of the generator and its power converter is much less than that of the engine.Since the generative power is dissipated in the hydraulic line as a loss,the capacity of the supercapacitor is also less than the other structures.Moreover,an only

minor

https://www.sodocs.net/doc/4c14173385.html,parison of the additional cost with respect to that of the series-type hybrid

excavator.

https://www.sodocs.net/doc/4c14173385.html,parison of the payback time with respect to that of the series-type hybrid

excavator.

Fig.8.(a)Notation of the power directions.(b)Block diagram of the power controller.

modi?cation of the hydraulic system is required;thus,the cost for this modi?cation would be neglected.

Fig.6shows the comparison result of the additional cost for composing each hybrid system.All of the value is normalized

KWON et al.:POWER CONTROL ALGORITHM FOR HYBRID EXCAVATOR WITH SUPERCAPACITOR

1451 Fig.9.State?owchart for the decision of the power commands of the generator and the supercapacitor.

with the cost for the series hybrid system.As expected,the series-type hybrid system requires a high cost,which is about 500%higher than that of the parallel-type hybrid system.

The compound-type hybrid system shows moderate charac-teristic for the fuel economy and additional cost.About25% reduction of the fuel consumption is expected compared with the conventional excavator.Although this value is almost half of that of the series-type hybrid system,the additional cost for the compound system is almost one-third of that for the series system.Fig.7shows this characteristic with payback time. Payback time means the time in which the fuel cost reduced by applying the hybrid system is equal to the additional cost for composing it.All the value in Fig.7is normalized by the payback time of the series hybrid system.The saved fuel cost is obtained under the assumption that the operation time is 2000h/year;during30%of the operation time,the excavator is idling,and for the rest of the time,the excavator is continuously repeating the work shown in Fig.3.

As shown in Fig.7,although the series hybrid shows the largest fuel reduction,it presents the longest payback time.It is because the cost of the electrical machines and their converters is still high,and if their price goes down in the future,then the results would be totally different.Hence,the best candidate structure,right now,is the compound-type hybrid system from the aspect of the economical reason,as shown in Fig.7.In addition to this point,the compound type and the parallel type can be considered as more reliable than the series-type excavator.In the series type,all the power?ows through the electric path;thus,if failure to keep the dc-link voltage occurs, then the total system would stop.However,in the compound and parallel types,both electric and mechanical paths can be used for the power?ow,and if one of them is to fail,then the total system can still be operated with unavoidable degraded performance.Thus,considering the economical point and the reliability,it can be concluded that the compound-type hybrid excavator is the best

solution.Fig.10.Simulation result of the compound hybrid controller with the pro-posed power control strategy.

III.P OWER C ONTROL S TRATEGY

Fig.8shows the block diagram of the power controller of the compound-type hybrid excavator.The power controller should provide a balance of the instantaneous power among the engine,the supercapacitor,and the load.It should also provide a balance of the supercapacitor energy during a period of a work. As shown in Fig.8,the power balance is achieved by the dc-link voltage control of the pulse width modulation converter, that is,the generator controls the dc-link voltage to a constant value in a feedback manner,and the energy balance is obtained by maintaining the supercapacitor voltage to a certain range in a feedforward manner,whereas the engine controls its speed to a nearly constant speed[4].The swing power is supplied by the supercapacitor or the generator according to the value of the Flag.In Fig.8,H sc and L sc are the upper and lower

1452IEEE TRANSACTIONS ON INDUSTRY APPLICATIONS,VOL.46,NO.4,JULY/AUGUST

2010 Fig.11.Simulation result of the compound hybrid controller.(a)DC link voltage.(b)Supercapacitor voltage.

limit values of the power command of the supercapacitor, respectively.Similarly,H gen and L gen denote the upper and lower limit values of the power command of the generator. These values are decided considering the maximum ef?ciency engine power P eng_max,the power requested by the hydraulic pump P Pump,and the voltage of the supercapacitor V sc using the state?owchart in Fig.9.It is notable that P eng_max does not mean the maximum engine power in the whole operating region of the engine,instead of that it means the engine power that shows the maximum ef?ciency at the speed where the engine is operated.When the voltage of the supercapacitor is in the range between its higher limit V sc_high and its lower limit V sc_low;the operating state corresponds to state1.In this state, the supercapacitor could be discharged or charged according to

P eng_max?P pump.Hence,the limit values of the power com-mands of the generator and the supercapacitor are set to their maximum values.The swing power is supplied or absorbed by the supercapacitor in this state,thus“Flag”is set to1.

If the voltage of the supercapacitor is larger than V sc_high, then the supercapacitor cannot be charged;thus,the lower limit of the power command of the supercapacitor L sc and the higher limit of the power command of the generator H gen are set to 0.The swing power is supplied by the supercapacitor if it is positive;this corresponds to state2,so“Flag”is set to1.Other-wise(state3),it is absorbed by the generator so the generator is operated in the motoring mode;thus,the regenerative power from the swing motion can share the power required by the hydraulic pump P Pump with the engine.Although the voltage of the supercapacitor is higher than V sc_high,the supercapacitor may be charged if the regenerative swing power is larger than the maximum power of the generator;thus,V sc_high should be selected considering the maximum regenerative power.

Fig.10shows the simulation result of the compound hybrid excavator at a certain moment with the power controller in Figs.8and9.It is assumed that the excavator conducts the work described by the load pro?le in Fig.3.From the top to the bottom in Fig.10,it represents the power of the hydraulic load and the swing motor,the voltage of the supercapacitor,the power of the generator,and the power of the supercapacitor. The values of the power are normalized by the maximum ef?ciency engine power,and the higher limit voltage of the supercapacitor is set to270V.From T1to T2,since the voltage of the supercapacitor is larger than its higher limit and the swing power is zero,this region corresponds to state2.Therefore,the generator is operated in motoring mode,and the supercapacitor is discharged according to the difference between the

hydraulic https://www.sodocs.net/doc/4c14173385.html,parison of the engine power between the conventional excavator and the hybrid excavator with the

supercapacitor.

Fig.13.(a)Comparison result of the fuel consumption and(b)pie chart of the reason of improvement.

load power and the engine maximum ef?ciency power.During T3–T4,the voltage of the supercapacitor is lower than its higher limit,so the rule of state1in Fig.9is applied.Thus,the swing power is supplied by the supercapacitor,and the generator tries to charge the supercapacitor.From T5to T6,the voltage of the supercapacitor is larger than its higher limit,and the swing power is negative;thus,the state4in Fig.9decides

KWON et al.:POWER CONTROL ALGORITHM FOR HYBRID EXCAVATOR WITH SUPERCAPACITOR

1453 Fig.14.Experimental setup for the engine dynamo

test.

Fig.15.(a)Pro?le of the load power for the dynamo meter and(b)simulated swing power.

the limit values of the power commands for the generator and the supercapacitor,and the regenerative swing power assists the engine through the generator.

Fig.11shows the dc-link voltage and the supercapacitor voltage during one work cycle of the excavator.It can be noticed that the balance of the instantaneous power among the engine, the supercapacitor,and the load is maintained,whereas the voltage of the supercapacitor is kept to a certain range during the cycle.

The comparison between the engine power of the conven-tional excavator and the hybrid excavator is shown in Fig.12.It is obvious that the engine power of the hybrid excavator is lower than that of the conventional one.It is because the engine of the hybrid excavator shares the load with the supercapacitor power through the generator.Another reason is that in the hybrid excavator,the swing motor is not fed by the engine directly,instead of that it is fed by the supercapacitor;thus,the loss in the hydraulic line can be reduced,and the regenerative power of the swing machine can be recuperated.

Fig.13shows the comparison result between the fuel con-sumption of the hybrid excavator and the conventional one with the proposed power control strategy and the contributions of the reasons for fuel reduction.It can be known that the hy-brid excavator could reduce the fuel consumption with the proposed power controller by about24%,and the most of the improvement comes from the ef?cient operation of the engine.

IV.E XPERIMENTAL R ESULTS

To prove the power control strategy proposed in Section III, the engine dynamo test is performed.Fig.14presents the ex-perimental setup,which shows the generator,which is directly

1454IEEE TRANSACTIONS ON INDUSTRY APPLICATIONS,VOL.46,NO.4,JULY/AUGUST

2010 Fig.16.Performance of the proposed power control strategy.

connected to the engine and the dynamo meter,the power converter,the supercapacitor,and the swing power simulator. The swing motion of the excavator is simulated in the power level by controlling the power from the power level.The load power pro?les for the dynamo meter and the simulated swing power are shown in Fig.15.All the values in Fig.15are normalized by the maximum ef?ciency engine power.Since the capacity of the dynamometer is not enough to cover the whole engine power,the tested load power is in the range between 20%and60%of the maximum ef?ciency engine power,as shown in Fig.15.Thus,40%of the“real”maximum ef?ciency engine power is taken as P eng_max for the proposed power control strategy shown in Figs.8and9.

Fig.16shows the performance of the proposed power control strategy.It can be shown that the dc-link voltage is well regulated in spite of the change of the load power and the swing power,and the voltage of the supercapacitor is kept in a certain range during the work cycle.This means that the proposed power controller achieves the instantaneous power balance and the energy balance during the work cycle.

To examine the effect on the fuel consumption,the load pro?le in Fig.15(a)is applied without the simulated swing power.Since in the hydraulic excavator the swing power is supplied by the engine through the hydraulic line,whereas in the hybrid excavator it is supplied through the electrical line, the simulated swing power is not applied for this comparison to compare more fairly.As a result,the authors obtain8%fuel reduction,whereas24%fuel saving is expected in Section III. It is because in these experiments,the load power level is too low compared with the maximum ef?ciency engine power and the regeneration power,and the idling state is omitted.

V.C ONCLUSION

In this paper,several structures of the hybrid excavator with the supercapacitor have been compared from the aspect of fuel ef?ciency,the additional cost due to the hybridization,and the expected payback time.From the comparison result,it can be concluded that a compound-type hybrid structure is the best solution among them because of its shortest expected payback time.In addition,the power control algorithm of the engine and the supercapacitor is proposed.To verify the proposed algorithm,computer simulation and experiments using engine dynamo set were performed,and the results are presented.

From the result,it can be known that the proposed power controller can keep the balance of the instantaneous power and the energy of the supercapacitor.Moreover,about24% of the reduction of the fuel consumption with this controller is expected,and8%fuel reduction can be obtained by the engine dynamo test.The reason for this difference between these results is that,due to the limitation of the dynamo setup, the load power level is too low compared with the maximum ef?ciency engine power and the regeneration power,and the idling state is omitted.The implementation of the prototype 22-ton class hybrid excavator is in progress to show the fea-sibility of the proposed controller and system.

R EFERENCES

[1]https://www.sodocs.net/doc/4c14173385.html,ler,“Hybrid electric vehicle propulsion system architectures of

the e-CVT type,”IEEE Trans.Power Electron.,vol.21,no.3,pp.756–767,May2006.

[2]C.C.Chan,“The state of the art of electric vehicles technology,”Proc.

IEEE,vol.90,no.2,pp.247–275,Feb.2002.

[3]A.Emadi,K.Rajashekara,S.S.Williamson,and S.M.Lukic,“Topo-

logical overview of hybrid electric and fuel cell vehicular power system architectures and con?gurations,”IEEE Trans.Veh.Technol.,vol.54, no.3,pp.763–770,May2005.

[4]S.-M.Kim and S.-K.Sul,“Control of the rubber tyred gantry crane

with energy storage based on super capacitor bank,”IEEE Trans.Power Electron.,vol.21,no.5,pp.1420–1427,Sep.2006.

[5]D.H.Clayton,S.D.Sudhoff,and G.F.Grater,“Electric ship drive and

power system,”in Conf.Rec.24th Int.Power Modular Symp.,Jun.2000, pp.85–88.

[6]A.Monti,D.Boroyevich,and D.Cartes,“Ship power system control:

A technology assessment,”in Proc.IEEE Elect.Ship Technol.Symp.,

Jul.2005,pp.292–297.

[7]S.-Y.Kim,Y.-D.Yoon,and S.-K.Sul,“Suppression of the thrust loss for

the maximum thrust operation in the electric propulsion ship,”in Proc.

IEEE Elect.Ship Technol.Symp.,May2007,pp.72–76.

[8]H.Yoshimatsu,“Driving device of working machine,”Japan Patent2001-

12274,Jan.16,2001.

[9]Q.Xiao,Q.Wang,and Y.Zhang,“Control strategies of power sys-

tem in hybrid hydraulic excavator,”Autom.Construct.,vol.17,no.4, pp.361–367,May2008.[Online].Available:https://www.sodocs.net/doc/4c14173385.html,/ locate/autcon/

[10]M.Kagoshima,T.Sora,and M.Komiyama,“Hybrid construction equip-

ment power control apparatus,”U.S.Patent7069673,Jul.4,2006. [11]E.J.Cegnar,H.L.Hess,and B.K.Johnson,“A purely ultracapacitor

energy storage system hybrid electric vehicles utilizing a based DC–DC boost converter,”in Proc.IEEE Appl.Power Electron.Conf.Expo., May2004,vol.2,pp.1160–1164.

[12]B.Maher,Ultracapacitors and Hybrid Vehicle.[Online].Available:http://

https://www.sodocs.net/doc/4c14173385.html,/pdf/uc/white-apers/utracapacitors_and_hevs.pdf [13]https://www.sodocs.net/doc/4c14173385.html,ler and M.Everett,“An assessment of ultra-capacitors as the

power cache in Toyota THS-II,GM-Allision AHS-2and Ford FHS hybrid propulsion systems,”in Proc.IEEE Appl.Power Electron.Conf.Expo., Mar.2005,vol.1,pp.481–490.

KWON et al.:POWER CONTROL ALGORITHM FOR HYBRID EXCAVATOR WITH SUPERCAPACITOR

1455

Tae-Suk Kwon(S’04–M’08)was born in Seoul,

Korea,in1973.He received the B.S.and M.S.de-

grees in electrical engineering from Hanyang Uni-

versity,Seoul,in1995and1997,respectively,and

the Ph.D.degree in electrical engineering from Seoul

National University,Seoul,in2007.

From1997to2003,he was a Research Engineer

with Hyundai Elevator Company Technical R&D

Center,Ichon,Korea,where he developed high-

speed gearless elevator systems.Since2008,he has

been a Principal Engineer with Hyundai MOBIS Company,Seoul.His interests include high-performance ac drive systems and

hybrid electric vehicle

drives.

Seon-Woo Lee was born in Korea in1982.He received the B.S.degree in electronic and electrical engineering from Hanyang University,Seoul,Korea, in2006,and the M.S.degree in electrical engineering and computer science from Seoul National Univer-sity,Seoul,in2008.

Since2008,he has been a Research Engineer with the Automation R&D Center,LS Industrial Sys-tems Company,Anyang,Korea.His current research project is the development of the100-kV A IGBT inverter for high-speed electric

vehicles.

Seung-Ki Sul(S’78–M’80–SM’98–F’00)was born

in Korea in1958.He received the B.S.,M.S.,and

Ph.D.degrees in electrical engineering from Seoul

National University,Seoul,Korea,in1980,1983,

and1986,respectively.

From1986to1988,he was an Associate

Researcher in the Department of Electrical and

Computer Engineering,University of Wisconsin,

Madison.From1988to1990,he was a Principal Re-

search Engineer with Gold-Star Industrial Systems

Company.Since1991,he has been a member of the

faculty of the School of Electrical Engineering,Seoul National University,

where he is currently a Professor.His current research interests are power

electronic control of electric machines,electric/hybrid vehicle drives,and

power-converter

circuits.

Cheol-Gyu Park was born in Korea in1969.He

received the B.S.,M.S.,and Ph.D.degrees in me-

chanical design and production engineering from

Seoul National University,Seoul,Korea,in1991,

1993,and1999,respectively.

Since1999,he has been with the Institute of Tech-

nology,Doosan Infracore Company,Ltd.,Yongin,

Korea,where he is currently a Principal Researcher.

His application areas are modeling of hydraulic sys-

tems,control of dynamic systems,and hybrid power

train systems for construction

equipment.

Nag-In Kim(S’85–M’87)was born in Korea in

1962.He received the B.S.degree in mechanical en-

gineering from Korea Aviation University,Goyang,

Korea,and the M.S.and Ph.D.degrees in mechanical

engineering from the Korea Advanced Institute of

Science and Technology,Daejeon,Korea.

Since1987,he has been with the Institute of Tech-

nology,Doosan Infracore Company,Ltd.,Yongin,

Korea,where he is currently Managing Director.

His current interests include technology planning of

the corporation and eco-technologies,such as hybrid

vehicle and low-temperature combustion of diesel

engine.

Byung-il Kang was born in Korea in1975.He

received the B.S.and M.S.,degrees in mechanical

engineering from Korea University,Seoul,Korea,in

1998and2000,respectively.

In2000,he joined Doosan Infracore,Yongin,

Korea,where he is currently a Senior Research En-

gineer.His application areas are simulation,design,

and test of hydraulic systems.His current research

interests include hydraulic systems for increasing the

ef?ciency of hybrid power train systems for con-

struction

equipment.

Min-seok Hong was born in Korea in1971.He

received the B.S.degree in electrical engineering

from Myongji University,Korea,in1995.

Since1995,he has been with the Institute of Tech-

nology,Doosan Infracore,Yongin,Korea,where he

is currently a Senior Researcher.His current research

interests include power electronics and ac motor

control.

酒店前台服务员管理规章制度

---------------------- 前台规章制度 一、仪容仪表 1. 上班时间需化淡妆,长发须佩戴头花或盘起。 2. 着装必须干净整洁,必须穿工作服上班。 3. 不能留长指甲,不能涂指甲油,不能佩戴夸张的饰品。 4. 保持最佳的精神状态工作。 二、工作纪律 1. 上班时间,不能吃东西、上网看电视,打接与工作无关的电话时间不能过长(特殊情况和家里重大事情除外)。 2. 上班时间不能在前台睡觉、不能串岗、不能拿上班时间会客,不能大声喧哗。 3.上班时间不能无故缺席,离岗时要在登记表做好记录(楼层巡检,吃饭,检查各个会议室等)不得无故闲逛。 三、工作规定 1. 上班期间服务态度好。主动向客人问好、站立服务、耐心的与客人交流,让客人在酒店住的舒适。 2. 员工不能把私人情绪带入工作中,随时随地对客人保持微笑。 3. 不能拿酒店财物私用或带回家(如有发现一律重罚或开除)。 4. 时刻保持前台的清洁。 5. 员工不能徇私舞弊,互相包庇。 6. 当班人员上班,不能迟到早退、不能擅自离岗、不能私自换班(需提前报告领导写好换班条,待领导审批,通过方可换班)、不能无故旷工(特殊情况可向部门领导请示)。 以上规章制度一经核实,发现第一次给予警告,第二次给予罚款,犯多次或屡教不改者,公司有权给予开除处理。 备注:(罚款方式:第一次20元,第二次50元,情况严重者重罚) ---------------------------------------------------------精品文档

---------------------- ---------------------------------------------------------精 品 文档前台工作内容 1. 为客人办理入住登记并请客人签字确认,认付款方式(挂账、现金,)问明付过押金后给客人房卡,并向客人解释房卡内容,在电脑中及时占房,发放早餐卷。 2.住宿登记单上,住几个人写几个人的名字,以便开门。入住时要询问客人住几天,以便刷几天的房卡,收几天的房费。同时,电脑上时间也要与此一致, 以方便楼层。坚持姓氏称呼。 3.阅读交班本,了解上一班未完成事项,及时进行跟进和处理。 4.查看各部门钥匙使用和归还纪录情况,并将钥匙分类放置。 5.核对房态,确保房态正确,清点房卡,所有一致加起来数目和上一班交接相符和。 6.如有客人要求换房,确定已通知客房服务人员和楼层服务人员进行打扫,检查。确认无误,收回房卡,发放新的发卡为客人换房。 7.了解每日会议信息和会议用房数,若会议举办方有任何要求,及时与楼层服务员和客房服务 员联系并跟进。

酒店房卡管理规定

酒店房卡管理规定 一、房卡类别 1、客房房卡分总控卡、领班卡、楼层卡、客人卡。 2、总控卡由相关管理人员持有。 3、领班卡由各楼层领班持有。 4、楼层卡各楼层员工持有。 5、客人卡由前台员工保管、制作。 注:若领班卡、楼层卡丢失或损坏,应立即上报部门,采取相应的措施(消磁和补办),当班人员要有补办记录,以免酒店遭受损失 二、房卡管理 1、总控卡由总经理、副总经理、前厅部经理、客房部经理、大堂经理持有。 2、领班卡、楼层卡由客房服务中心保管,实行每天签字借用制度。 ⑴领班卡用于查房使用,此卡可以开启所管辖的楼层所有客房房门。 ⑵楼层卡用于服务员打扫卫生使用,按照服务员的工作范围制作。 ⑶调换楼层时要有交接手续。

3、持卡人不得将自己的卡借给其他人员使用,一定发现必将严惩。 4、客人卡的管理制度: ⑴将客房卡交给客人前,前台员工必须确认客人身份; ⑵前台原则上单人房每间只发放一张房卡,双人房根据客人要求可发放两张房卡,并在电脑中注明数量; ⑶客人房卡遗失: 验明客人身份和登记相符→说明规定,向客人收取或从押金中扣除赔偿费→重新制作l张新的房卡给客人→确保前一张房卡作废。 ⑷客人钥匙损坏: A. 验卡→显示房号和客人所报相同,且在期限内→重新制作一张房卡给客人,并与客人说明赔偿费用。 B. 如果卡号不能显示或不能验卡→验明客人身份和登记相符→重新制作1张房卡给客人,并向客人说明赔偿费用。 ⑸客人寄存钥匙: A. 听清客人所报房号,请客人稍等→验卡→显示房号和客人所报一致,取房卡袋填写房号,将房卡插入房卡袋内,放在抽屉内→客人来取时,验明身份后,交还房卡。 B. 如验卡时,房号不能显示,应先验明身份,再进行寄

酒店前台房卡管理规定

酒店前台房卡管理规定 SANY GROUP system office room 【SANYUA16H-

前台房卡管理规定 一、房卡类别: 1、客房房卡分总控卡、领班卡、楼层卡、客人卡。 2、总控卡店级领导、客房相关管理人员持有(董事长、总经理、副总经理、客务总监、客房经理) 3、领班卡由各楼层领办持有 4、楼层卡各楼层员工持有 5、客人卡由前台员工制作 注:若领班卡、楼层卡丢失或损坏,应立即上报部门,采取相应的措施(消磁和补办),前台要有补办记录,以免酒店遭受损失 二、客人卡的管理制度: 1、将客房匙交给客人前,前台员工必须确认客人身份; 2、前台原则上单人房每间只发放一条房匙,双人房根据客人要求可发放两条房匙,并在电脑中注明; 3、客人房卡遗失: 验明客人身份和登记相符→说明规定,向客人收取或从押金中扣除赔偿费(30元)→重新制作l把新的钥匙给客人→通知房务中心→使用管理卡到该房间插一次卡(做消磁处理),确保插卡前使用的钥匙作废。 4、客人钥匙损坏: A.验卡→显示房号和客人所报相同,且在期限内→重新制作l把钥匙给客人,并向客人致歉。 B.如果卡号不能显示或不能验卡→验明客人身份和登记相符→重新制作1把钥匙给客人,并向客人致歉。 5、客人寄存钥匙: A.听清客人所报房号,请客人稍等→验卡→显示房号和客人所报一致,取房卡填写房号,钥匙插入新房卡,放在寄存抽屉内→客人来取时,验明身份后,交还钥匙,将写房号的房卡撕毁。 B.如验卡时,房号不能显示,应先验明身份,重新制作钥匙,再进行寄存。 C.如客人寄存时嘱咐他人来取→填写留言单,请客人签字确认→钥匙、留言单放在房卡中存放于收银抽屉内→领取时验明身份→留言单保留在客帐内直至客人退房。 6、客人退房时,前台员工应提醒客人交还房匙→如客人出示的钥匙没有房卡或押金单证明其房号,必须验卡验证无误后,方可通知客房服务员查房并办理退房手续。 7、退房时,客人将钥匙留在房间:客房服务员查完房交到前台。凡有折痕、断裂、明显污迹、坏的钥匙,交前台主管保管。

房卡管理制度

酒店前台房卡管理 一、房卡类别及制卡权限: 1、客房房卡分总卡、领班卡、楼层卡、客人卡 2、总卡为客房相关管理人员持有(董事长、总经理、副总经理、客务总监、客 房经理、前厅经理)由前厅经理制作 3、领班卡由各楼层领办持有由大堂副理或前厅经理制作 4、楼层卡各楼层员工持有由大堂副理制作 5、客人卡由前台员工制作 二、客人卡的管理制度: 1、将房卡交给客人前,前台员工必须确认客人身份; 2、前台原则上单人房每间只发放一张房卡,双人房根据客人要求可发放两张房 卡,并在电脑中注明; 3、客人房卡遗失: 验明客人身份和登记相符→说明规定,向客人收取或从押金中扣除赔偿费(50元)→重新制作一张新的房卡给客人→通知房务中心→使用管理卡到该房间插一次卡(做消磁处理),确保插卡前使用的房卡作废。 4、客人房卡损坏: 1)验卡→显示房号和客人所报相同,且在期限内→重新制作一张房卡给客人, 并向客人致歉。 2)如果房卡号不能显示或不能验卡→验明客人身份和登记相符→重新制作一 张房卡给客人,并向客人致歉。

5、客人寄存房卡: 1)听清客人所报房号,请客人稍等→验卡→显示房号和客人所报一致,取 房卡套填写房号,房卡插入房卡套,放在寄存抽屉内→客人来取时,验明身份后,交还房卡,将写房号的房卡套撕毁。 2)如验卡时,房号不能显示,应先验明身份,重新制作房卡,再进行寄存。 3)如客人寄存时嘱咐他人来取→填写留言单,请客人签字确认→房卡、留 言单放在房卡中存放于收银抽屉内→领取时验明身份→留言单保留在客帐内直至客人退房。 6、客人退房时,前台员工应提醒客人交还房卡→如客人出示的房卡没有房卡 或押金单证明其房号,必须验卡验证无误后,方可通知客房服务员查房并办理退房手续。 7、退房时,客人将房卡留在房间:客房服务员查完房交到前台。凡有折痕、断 裂、明显污迹、坏的房卡,交前台主管保管并做记录。 8、未经登记客人许可,不得为任何来访者开启客人房间或发卡给来访者; 9、任何服务员如发现房卡遗留于公共场所,应立即交当值主管,送回前台接待 处处理; 10、客房服务员不得对客人以错放房卡在房间内为由,随便开房门让客人进入, 应即时打电话到前台接待处核实客人身份,如有任何疑问,应请客人到前台接待处办理补卡手续。 11、前台服务员每班交接时,必须核对客人房卡数量。发现任何缺失必须上报 并在交接本上作记录。 12、所有房卡上不能贴房号

星级酒店房卡管理守则4.doc

星级酒店房卡管理制度4 一、房卡类别: 1、客房房卡分总控卡、领班卡、楼层卡、客人卡。 2、总控卡店级领导、客房相关管理人员持有(董事长、总经理、副总经理、客务总监、客房经理) 3、领班卡由各楼层领办持有 4、楼层卡各楼层员工持有 5、客人卡由前台员工制作 注:若领班卡、楼层卡丢失或损坏,应立即上报部门,采取相应的措施(消磁和补办),前台要有补办记录,以免酒店遭受损失 二、客人卡的管理制度: 1、将客房匙交给客人前,前台员工必须确认客人身份; 2、前台原则上单人房每间只发放一条房匙,双人房根据客人要求可发放两条房匙,并在电脑中注明; 3、客人房卡遗失: 验明客人身份和登记相符→说明规定,向客人收取或从押金中扣除赔偿费(30元)→重新制作l把新的钥匙给客人→通知房务 中心→使用管理卡到该房间插一次卡(做消磁处理),确保插

卡前使用的钥匙作废。 4、客人钥匙损坏: A.验卡→显示房号和客人所报相同,且在期限内→重新制作l把钥匙给客人,并向客人致歉。 B.如果卡号不能显示或不能验卡→验明客人身份和登记相符→重新制作1把钥匙给客人,并向客人致歉。 5、客人寄存钥匙: A.听清客人所报房号,请客人稍等→验卡→显示房号和客人所报一致,取房卡填写房号,钥匙插入新房卡,放在寄存抽屉内→客人来取时,验明身份后,交还钥匙,将写房号的房卡撕毁。 B.如验卡时,房号不能显示,应先验明身份,重新制作钥匙,再进行寄存。 C.如客人寄存时嘱咐他人来鳃填写留言单,请客人签字确认→钥匙、留言单放在房卡中存放于收银抽屉内→领取时验明身份→留言单保留在客帐内直至客人退房。 6、客人退房时,前台员工应提醒客人交还房匙→如客人出示的钥匙没有房卡或押金单证明其房号,必须验卡验证无误后,方可通知客房服务员查房并办理退房手续。 7、退房时,客人将钥匙留在房间:客房服务员查完房交到前台。凡有折痕、断裂、明显污迹、坏的钥匙,交前台主管保管。 8、未经登记客人许可,不得为任何来访者开启客人房间或

客房部房卡管理制度

客房部房卡管理制度及开门程序 房卡管理制度 1、作为客房部的任何一员,如将总卡或是楼层卡丢失,就等于丢掉自己的这份工作,后果是不堪设想的,因为这关系到酒店和客人的财产安全和人生安全问题; 2、所有持卡人都应做到卡不离人,不可将卡乱扔乱放,更不可 将卡随便给部门以外的人去开房门; 3、每天上下班或吃饭的时候,都应有交接卡的程序,做好交接 的登记; 4、不可将卡带离工作岗位,用餐或下班时应将卡交还房务中心保管; 5、每个持卡人都应爱护房卡,正确使用房卡。 敲门开门程序 1、客房部任何持卡人都应养成,不管是任何房态(也就是说: 不管是空房、住人房、锁房还是维修房等等”)都应养成敲门报服务员”的好习惯; 2、在开房门前首先要时刻了解所要开门的房间状态(即:房态),一般除住人房而外,我们只需敲一次房门报服务员”即可,而对 住客房来讲就不能简单化,不管此时房间是否有客或是无客,都应先按门铃三下或再敲三次房门,然后报:服务员”同时耳朵 要时刻关注房间有无动静(也就是说:是否听到有客人回应?”; 3、不可不敲门直接就拿房卡开门,或者是边敲门边插房卡开门,

还有任何人都不能抱有:我以为房间没有客人”的这种想法,而 直接插卡开门的话,将会酿成大错,这些可都是开门的大忌; 4、开门时要注意房卡芯片的朝向,同时要懂得识别电脑锁信号灯所表示的意思,电脑锁信号灯一般有以下四种表示意义: A、房卡芯片朝向正确和设置房号和门牌号对得上,插入房卡电脑锁会亮绿灯,你会听到嘟”一声,此时立即拔出房卡,此时又会听到电脑锁内弹簧回弹的声音,这时房门就可以打开了; B、房卡所设置的房号与门牌号对不上(也就是说:客人如果走错房间”,或者是房卡超时和插卡不到位,此时电脑锁会闪三下黄灯,房门是打不开的; C、任何房卡插反了,电脑锁都会亮红灯,抽出房卡红灯立即熄 灭,此时房门是打不开的; D如果房间里面打上防盗栓的话,此时用总卡、楼层卡、宾客卡开门,电脑锁都会先亮黄灯,再亮红灯,并且会有嘟”一声鸣响; E、不管你怎么插卡,电脑锁都不会亮灯的话,表示电脑锁没有电了,就要采取措施更换电池,方可用卡开门。 5、客房部任何持卡人都不能随便用自己的卡去帮客人开门,必 须确认客人身份无误后,方可用自己的卡帮客人开门,一般客人开不了门并要求帮其开门有以下几种情况: A、客人有卡,没欢迎卡,走错房间; B、客人有卡,有/无欢迎卡,但客人不会开;

酒店房卡管理制度

南融全际酒店 房卡管理制度 一、房卡类别: a)客房房卡分总裁卡、管理卡、总控卡、领班卡、楼层卡、客人卡。 b)总裁卡、管理卡、总控卡由总经办班相关管理人员持有(总经理、总助) c)领班卡由客房经理和客房主管、领班持有 d)楼层卡由各楼层客房部员工持有 e)客人卡由前台员工制作 注:若领班卡、楼层卡丢失或损坏,应立即上报直属上级,采取相应措施(消磁 和补办),前台需有补办记录,以免酒店遭受损失 二、房卡操作流程 a)领班卡、楼层卡由客房部负责保管,必须存放在指定地方,客房经理须每天检查 b)楼层房卡由客房经理/主管在每日晨会时发放给服务员 c)服务员在领用和交接时必须在工作记录本上记录并签名确认 d)服务员在当班时才有权使用楼层卡在班次结束时需将楼层卡归还 e)服务员非工作需要不得擅自开启客房房门 f)不得随便为他人开启客房 g)客人在楼层要求开门,服务员请客人核对身份,用电话和前台核对(姓名、身份证、 入住日期等),待确认客人身份后方可为客人开启房门 h)按前台指示为客人开启房门 三、房卡保管 a)房卡要时刻随身携带,不得乱丢、乱放 b)严禁将房卡转借他人使用 c)丢失房卡,马上报告主管,查明原因,积极寻找 d)房卡严禁当取电卡使用 e)夜班员工领取领班卡 f)房卡归还必须有记录,并且签名确认 四、客人卡管理制度 a)客人入住前前台人员将客人房间房卡制作给客人 b)原则上每个房间只发放一张房卡,若客人需要两张房卡需收取相应的押金为客人发 放两张房卡并在电脑上注明,在交班记录本上做好交接 c)客人房卡遗失:验明客人身份和登记相符说明规定,向客人收取赔偿费重 新制作一把新的房卡给客人开具赔偿单签客人签字在交班记录本上做好 交接管理人员根据赔偿单到财务处领取新房卡 d)客人房卡损坏:验卡显示房号和客人所报相同,且房卡还未过期核对客

酒店管理规范

客房服务流程及规范 一、目的:为了规范客房服务人员的服务行为,提高酒店的客房服务水平, 提升客户对服务的满意度,特制定工作标准。 二、员工仪容仪表: 1.手指甲不得超过0、5毫米,时刻保持清洁,不可涂指甲油; 2.经常理发,头发梳理整齐。保持前不遮眉、中不盖耳、后不过领,女士 长发要简单盘于脑后。男士胡须应始终修剪干净。 3.不可佩戴夸张首饰,男士只可带样式简单的手表; 4.整齐穿着酒店制服,制服要求干净整洁; 5.员工不可佩戴有色及大框眼镜; 6.女员工必须着淡妆,不可不化妆或化浓妆。 三、对客服务规范: 1.见到客人要侧身礼让并微笑点头问好; 2.与客人交谈时要有礼貌,必须使用礼貌用语; 3.对客人的额外要求,应立即报告主管; 4.不得向客人索要小费或礼品; 5.如果发现客人在房间里吵闹、发病或醉酒,立即通知主管; 6.非工作需要不得开启或进入客人房间,如因工作需要应先敲门经客人 允许后方可进入; 7.在客人房间做清洁时,不得翻瞧客人物品; 8.不得想客人泄露酒店管理秘密; 9.不得想客人泄露其她客人的信息及秘密; 10.不得私自为客人结账,应礼貌指引到前厅处。 四、物品发放流程及规范: 1.填写申请单 ①客房部凡领用物品,均须规定填写申请单; ②申请单须经主管与经理审批。 2.发放与盘点 ①凭经理审批后的申请单,有客房文员予以发放,发货时要注意物品 保质期,先进先发、后进后发; ②客房文员按时进行月度物品盘点存量。 3.做好发放记录 ①发放物品时,客房文员要以填好的物品领用单(含日期、名称、规 格、型号、数量、单价、用途等)为依据; ②客房文员要及时做好物品管理账簿,保证账物一致。

酒店前台房卡管理制度

酒店前台房卡管理制度 一、房卡类别: 1、客房房卡分总控卡、领班卡、楼层卡、客人卡。 2、总控卡店级领导、客房相关管理人员持有(董事长、总经理、副总经理、客务总监、客房经理) 3、领班卡由各楼层领班持有 4、楼层卡各楼层员工持有 5、客人卡由前台员工制作 注:若领班卡、楼层卡丢失或损坏,应立即上报部门,采取相应的措施(消磁和补办),前台要有补办记录,以免酒店遭受损失 二、客人卡的管理制度: 1、将客房匙交给客人前,前台员工必须确认客人身份; 2、前台原则上单人房每间只发放一条房匙,双人房根据客人要求可发放两条房匙,并在电脑中注明; 3、客人房卡遗失: 验明客人身份和登记相符→说明规定,向客人收取或从押金中扣除赔偿费(30元)→重新制作l把新的钥匙给客人→通知房务中心→使用管理卡到该房间插一次卡(做消磁处理),确保插卡前使用的钥匙作废。 4、客人钥匙损坏: A.验卡→显示房号和客人所报相同,且在期限内→重新制作l把钥匙给客人,并向客人致歉。 B.如果卡号不能显示或不能验卡→验明客人身份和登记相符→重新制作1把钥匙给客人,并向客人致歉。 5、客人寄存钥匙: A.听清客人所报房号,请客人稍等→验卡→显示房号和客人所报一致,取房卡填写房号,钥匙插入新房卡,放在寄存抽屉内→客人来取时,验明身份后,交还钥匙,将写房号的房卡撕

毁。 B.如验卡时,房号不能显示,应先验明身份,重新制作钥匙,再进行寄存。 C.如客人寄存时嘱咐他人来取→填写留言单,请客人签字确认→钥匙、留言单放在房卡中存放于收银抽屉内→领取时验明身份→留言单保留在客帐内直至客人退房。 6、客人退房时,前台员工应提醒客人交还房匙→如客人出示的钥匙没有房卡或押金单证明其房号,必须验卡验证无误后,方可通知客房服务员查房并办理退房手续。 7、退房时,客人将钥匙留在房间:客房服务员查完房交到前台。凡有折痕、断裂、明显污迹、坏的钥匙,交前台主管保管。 8、未经登记客人许可,不得为任何来访者开启客人房间或发卡给来访者; 9、任何服务员如发现房卡遗留于公共场所,应立即交当值主管,送回前台接待处处理; 10、客房服务员不得对客人以错放锁匙在房间内为由,随便开房门让客人进入,应即时打电话到前台接待处核实客人身份,如有任何疑问,应请客人到前台接待处办理补匙手续。 11、前台服务员每班交接时,必须核对客人钥匙数量。发现任何缺失必须上报并在交接本上作记录。 10、所有IC卡上不能贴房号。

前台房卡管理规定

前台房卡管理规定 一、房卡类别: 1、客房房卡分总控卡、领班卡、楼层卡、客人卡。 2、总控卡店级领导、客房相关管理人员持有(董事长、总经理、副总经理、客务总监、客 房经理) 3、领班卡由各楼层领办持有 4、楼层卡各楼层员工持有 5、客人卡由前台员工制作 注:若领班卡、楼层卡丢失或损坏,应立即上报部门,采取相应的措施(消磁和补办),前台要有补办记录,以免酒店遭受损失 二、客人卡的管理制度: 1、将客房匙交给客人前,前台员工必须确认客人身份; 2、前台原则上单人房每间只发放一条房匙,双人房根据客人要求可发放两条房匙,并在电 脑中注明; 3、客人房卡遗失: 验明客人身份和登记相符→说明规定,向客人收取或从押金中扣除赔偿费(30元)→重新制作l把新的钥匙给客人→通知房务中心→使用管理卡到该房间插一次卡(做消磁处理),确保插卡前使用的钥匙作废。 4、客人钥匙损坏: A.验卡→显示房号和客人所报相同,且在期限内→重新制作l把钥匙给客人,并向客人 致歉。 B.如果卡号不能显示或不能验卡→验明客人身份和登记相符→重新制作1把钥匙给客 人,并向客人致歉。 5、客人寄存钥匙: A.听清客人所报房号,请客人稍等→验卡→显示房号和客人所报一致,取房卡填写房号, 钥匙插入新房卡,放在寄存抽屉内→客人来取时,验明身份后,交还钥匙,将写房号的房卡撕毁。 B.如验卡时,房号不能显示,应先验明身份,重新制作钥匙,再进行寄存。 C.如客人寄存时嘱咐他人来取→填写留言单,请客人签字确认→钥匙、留言单放在房卡 中存放于收银抽屉内→领取时验明身份→留言单保留在客帐内直至客人退房。 6、客人退房时,前台员工应提醒客人交还房匙→如客人出示的钥匙没有房卡或押金单证明 其房号,必须验卡验证无误后,方可通知客房服务员查房并办理退房手续。 7、退房时,客人将钥匙留在房间:客房服务员查完房交到前台。凡有折痕、断裂、明显污 迹、坏的钥匙,交前台主管保管。 8、未经登记客人许可,不得为任何来访者开启客人房间或发卡给来访者; 9、任何服务员如发现房卡遗留于公共场所,应立即交当值主管,送回前台接待处处理; 10、客房服务员不得对客人以错放锁匙在房间内为由,随便开房门让客人进入,应即时打电 话到前台接待处核实客人身份,如有任何疑问,应请客人到前台接待处办理补匙手续。 11、前台服务员每班交接时,必须核对客人钥匙数量。发现任何缺失必须上报并在交接本上 作记录。 12、所有IC卡上不能贴房号。

酒店安全管理制度

酒店安全管理制度 总则 一、为了加强酒店的安全监督管理,防止和减少安全事故,保障酒店、客人和员工的生命和财产安全,促进酒店经营管理的健康发展,根据《中华人民共和国安全法》和有关法律法规的规定,特制定本规定。 二、酒店设安全管理委员会,由总经理任主任委员,副主任委员由酒店副总担任,以协管酒店工保部工作。安全管理委员会其他委员由各部门负责人担任,并由总经理任命。安全管理委员会的常设办事机构为工保部,安全日常工作由工保部负责,档案管理由总经办负责。 三、各部门应根据本部门各岗位的工作特点,依照国家及行业的有关劳动安全规定及技术标准,制定和不断完善本部门各类劳动安全管理制度和操作规程。 四、各部门制定的各类劳动安全管理规章制度,须报总经办备案。 五、在发生安全事故时,可根据酒店总经理指示成立事故处理小组,并按酒店制定的《安全管理工作程序和报告制度》(见附件一)进行妥善处置。 六、酒店劳动安全实行酒店、部门、班组三级管理。 七、酒店安全管理委员会的职责: 1、组织、指导各部门贯彻落实国家的安全方针和有关政策、规定。 2、教育各部门管理人员尊章守法,带头搞好安全。 3、听取各部门安全方面的情况汇报,发现问题及时找有关人员研究解决。 4、协调各部门安全工作,调查、布置、指导、检查安全情况,发现问题立即纠正。 5、负责随时检查、通报各部门劳动安全管理的执行情况,对出现的各类不安全问题及职业伤害事故进行调查分析,并提出处理意见和整改措施。 八、部门负责人安全职责: 1、在酒店安全管理委员会的领导下,对本部门执行安全规章制度的情况进行经常性的监督检查,对各岗位、设备的安全操作和安全运行进行监督。 2、向酒店安全管理委员会提交安全书面工作意见,主要包括:针对部门的安全隐患提出防范措施、隐患整改方案、安全技术措施和经费开支计划。 3、参与制定酒店和部门防止伤亡、火灾事故和职业危害的措施及危险岗位、危险设备的安全操作规程,并负责督促实施。 4、经常进行现场安全检查,及时发现、处理事故隐患。如有重大问题,应以书面形式

客房部房卡管理制度及开门程序

房卡管理制度 1、作为客房部的任何一员,如将总卡或是楼层卡丢失,就等于丢掉自己的这份工作,后果是不堪设想的,因为这关系到酒店和客人的财产安全和人生安全问题; 2、所有持卡人都应做到卡不离人,不可将卡乱扔乱放,更不可将卡随便给部门以外的人去开房门; 3、每天上下班或吃饭的时候,都应有交接卡的程序,做好交接的登记; 4、不可将卡带离工作岗位,用餐或下班时应将卡交还房务中心保管; 5、每个持卡人都应爱护房卡,正确使用房卡。 敲门开门程序 1、客房部任何持卡人都应养成,不管是任何房态(也就是说:“不管是空房、住人房、锁房还是维修房等等”)都应养成敲门报“服务员”的好习惯; 2、在开房门前首先要时刻了解所要开门的房间状态(即:房态),一般除住人房而外,我们只需敲一次房门报“服务员”即可,而对住客房来讲就不能简单化,不管此时房间是否有客或是无客,都应先按门铃三下或再敲三次房门,然后报:“服务员”,同时耳朵要时刻关注房间有无动静(也就是说:“是否听到有客人回应?”); 3、不可不敲门直接就拿房卡开门,或者是边敲门边插房卡开门,还有任何人都不能抱有:“我以为房间没有客人”的这种想法,而直接插卡开门的话,将会酿成大错,这些可都是开门的大忌; 4、开门时要注意房卡芯片的朝向,同时要懂得识别电脑锁信号灯所表示的意思,电脑锁信号灯一般有以下四种表示意义: A、房卡芯片朝向正确和设置房号和门牌号对得上,插入房卡电脑锁会亮绿灯,你会听到“嘟”一声,此时立即拔出房卡,此时又会听到电脑锁内弹簧回弹的声音,这时房门就可以打开了; B、房卡所设置的房号与门牌号对不上(也就是说:“客人如果走错房间”),或者是房卡超时和插卡不到位,此时电脑锁会闪三下黄灯,房门是打不开的; C、任何房卡插反了,电脑锁都会亮红灯,抽出房卡红灯立即熄灭,此时房门是打不开的; D、如果房间里面打上防盗栓的话,此时用总卡、楼层卡、宾客卡开门,电脑锁都会先亮黄灯,再亮红灯,并且会有“嘟”一声鸣响; E、不管你怎么插卡,电脑锁都不会亮灯的话,表示电脑锁没有电了,就要采取措施更换电池,方可用卡开门。 5、客房部任何持卡人都不能随便用自己的卡去帮客人开门,必须确认客人身份无误后,方可用自己的卡帮客人开门,一般客人开不了门并要求帮其开门有以下几种情况: A、客人有卡,没欢迎卡,走错房间; B、客人有卡,有/无欢迎卡,但客人不会开;

酒店客房部管理制度流程

一、房务部规章制度 “宾客至上、服务第一”是我们的服务宗旨:客人永远是对的,是我们的座右铭。对此,每一个前台人员务必深刻、领会、贯彻到一言一行中去。 酒店业是服务行业,我们要发扬中国传统的礼节和好客之道,树立服务光荣的思想,加强服务意识,竭力提供高效、准确、礼貌的服务,这宾客创一个“宾至如归”的境界。 1)仪表、仪态: (一)本部门员工以站立姿势服务,总台夜班员工十二点以后方坐,但若有客人前来,当即起立。 (二)在服务区域内,身体不得东歪西倒,前倾后靠,不得伸懒腰、驼背、耸肩、不得扎堆聊天。 (三)不配带任何饰物、留长指甲、女员工不得涂色在指甲上。 (四)必须佩带工号牌,工号牌应佩带在左胸处,不得任其歪歪扭扭,注意修整,发现问题及时纠正,从后台进入服务区域之前,也应检查仪容仪表。 2)表情、言谈: (一)面对客人应表现出热情、亲切、真实、友好,必要时要有同情的表情,做到精神振奋、情绪饱满、不卑不亢。(二)和客人交谈时应眼望对方,频频点头称是。 (三)双手不得叉腰,交叉腰前,插入衣裤或随意乱放,不抓头,抓痒,挖耳,抠鼻孔,不得敲桌子,鼓击或摆弄其它物品。 (四)不得哼歌曲,吹口哨,跺脚,不得随地吐痰,乱蓬蓬丢杂物,不得当众整理个人衣物,不得将任何物件夹于腋下。 (五)在客人面前不得经常看表。 (六)咳嗽,打喷嚏时应转身向后,并说对不起。 (七)不得大声谈笑、说话、喊叫,乱丢碰物品,发出不必要声响。 (八)上班时间不得抽烟、吃食物。 (九)不得用手指或笔杆指客人和为人指示方向。 (十)要注意自我控制,随时注意自己的言行举动。在与客人讲话时应全身贯注,用心倾听,不得东张西望,心不在焉。 (十一)在为客人服务时不得流露出厌烦、冷淡、愤怒、僵硬、紧张和恐惧的表情,不得扭捏作态,做鬼脸、吐舌、眨眼。 (十二)员工在服务、工作、打电话和与客人交谈时,如有客人走近,应立即示意,以表示已注意他(她)的来临,不得无所表示,等客人开口。 (十三)不得以任何借口顶撞、讽刺、挖苦客人。 (十四)指第三者是不能讲他(她),应称那位先生或那位女士。 (十五)离开面对客人,一律讲“请稍候”,如果离开时间较长,回来后要讲“对不起,让你久等”,不得一言不发就开始服务。 3)制服: (一)制服应干净、整齐、笔挺。 二)纽扣要全部扣好,穿西装制服时,第一颗纽扣须扣上,不得敞开外衣,卷起裤脚,衣袖,领带必须给正。(三)行李员不得不戴制服帽出现在服务区域内。 4)电话: (一)所有来电务必在三响之内接答。

房卡管理规定

房卡管理规定 一、房卡类别: 1、客房房卡分总控卡、领班卡、楼层卡、客人卡。 2、总控卡由相关管理人员持有。 3、领班卡由各楼层领班持有。 4、楼层卡各楼层员工持有。 5、客人卡由前台员工保管、制作。 注:若领班卡、楼层卡丢失或损坏,应立即上报部门,采取相应的措施(消磁和补办),前厅部要有补办记录,以免酒店遭受损失 二、房卡管理 1、总控卡由项目经理、项目副经理、前厅部经理、客房部经理、值班经理持有。 2、领班卡、楼层卡由客房服务中心保管,实行每天签字借用制度。 ⑴领班卡用于查房使用,此卡可以开启所管辖的楼层所有客房房门。 ⑵楼层卡用于服务员打扫卫生使用,按照服务员的工作范围制作。 ⑶调换楼层时要有交接手续。 3、客人卡的管理制度: ⑴将客房卡交给客人前,前台员工必须确认客人身份; ⑵前台原则上单人房每间只发放一张房卡,根据客人实际要求可发放两张房 卡,并在电脑中注明数量; ⑶客人房卡遗失: 验明客人身份和登记相符→说明规定,向飞行大队相关负责部门或负责人报告→重新制作l张新的房卡给客人→确保前一张房卡作废。 ⑷客人钥匙损坏: A. 验卡→显示房号和客人所报相同,且在期限内→重新制作l张房卡给客人,。

B. 如果卡号不能显示或不能验卡→验明客人身份和登记相符→重新制作1张 房卡给客人,并向客人说明。 ⑸客人寄存钥匙: A. 听清客人所报房号,请客人稍等→验卡→显示房号和客人所报一致,取房卡 袋填写房号,将房卡插入房卡袋内,放在抽屉内→客人来取时,验明身份后,交还房卡。 B. 如验卡时,房号不能显示,应先验明身份,再进行寄存。 C. 如客人寄存时嘱咐他人来取→填写留言单,请客人签字确认→房卡、留言单 放在房卡袋中存放于抽屉内→领取时验明身份→留言单保留在客帐内直至客人退房。 ⑹客人退房时,前台员工应提醒客人交还房卡→必须验卡无误后,方可通知客 房服务员查房并办理退房手续。 ⑺退房时,客人将房卡留在房间:客房服务员查完房交到房务中心→礼宾员/ 服务员取回送至总台。 ⑻未经登记客人许可,不得为任何来访者开启客人房间或发卡给来访者; ⑼任何服务员如发现房卡遗留于公共场所,应立即交当值经理,送回前台接待 处处理; ⑽客房服务员不得对客人以错放房卡在房间内为由,随便开房门让客人进入,应即时打电话到前台接待处核实客人身份,如有任何疑问,应请客人到前台接待处办理补卡手续。 ⑾前台服务员每班交接时,必须核对客人房卡数量。发现任何缺失必须上报并在交接本上作记录。 ⑿所有房卡上不能贴房号。(房卡套未到之前,总台制作客人卡可使用房号贴)

酒 店 房 卡 管 理 规 定

酒店房卡管理规定 一、房卡类别: 1、客房房卡分总控卡、领班卡、楼层卡、客人卡。 2、总控卡由相关管理人员持有。 3、领班卡由各楼层领班持有。 4、楼层卡各楼层员工持有。 5、客人卡由前台员工保管、制作。 注:若领班卡、楼层卡丢失或损坏,应立即上报部门,采取相应的措施(消磁和补办),网络班要有补办记录,以免酒店遭受损失 二、房卡管理 1、总控卡由总经理、副总经理、前厅部经理、客房部经理、大堂经理持有。 2、领班卡、楼层卡由客房服务中心保管,实行每天签字借用制度。 ⑴领班卡用于查房使用,此卡可以开启所管辖的楼层所有客房房门。 ⑵楼层卡用于服务员打扫卫生使用,按照服务员的工作范围制作。 ⑶调换楼层时要有交接手续。 3、客人卡的管理制度: ⑴将客房卡交给客人前,前台员工必须确认客人身份; ⑵前台原则上单人房每间只发放一张房卡,双人房根据客人要求可发放两张 房卡,并在电脑中注明数量; ⑶客人房卡遗失: 验明客人身份和登记相符→说明规定,向客人收取或从押金中扣除赔偿费(30元)→重新制作l张新的房卡给客人→确保前一张房卡作废。 ⑷客人钥匙损坏:

A. 验卡→显示房号和客人所报相同,且在期限内→重新制作l张房卡给客人,并与客人说明赔偿费用。 B. 如果卡号不能显示或不能验卡→验明客人身份和登记相符→重新制作1张 房卡给客人,并向客人说明赔偿费用。 ⑸客人寄存钥匙: A. 听清客人所报房号,请客人稍等→验卡→显示房号和客人所报一致,取房卡 袋填写房号,将房卡插入房卡袋内,放在抽屉内→客人来取时,验明身份后,交还房卡。 B. 如验卡时,房号不能显示,应先验明身份,再进行寄存。 C. 如客人寄存时嘱咐他人来取→填写留言单,请客人签字确认→房卡、留言单 放在房卡袋中存放于抽屉内→领取时验明身份→留言单保留在客帐内直至客人退房。 ⑹客人退房时,前台员工应提醒客人交还房卡→必须验卡无误后,方可通知客 房服务员查房并办理退房手续。 ⑺退房时,客人将房卡留在房间:客房服务员查完房交到房务中心→礼宾员取 回送至总台。 ⑻未经登记客人许可,不得为任何来访者开启客人房间或发卡给来访者; ⑼任何服务员如发现房卡遗留于公共场所,应立即交当值主管,送回前台接待 处处理; ⑽客房服务员不得对客人以错放房卡在房间内为由,随便开房门让客人进入,应即时打电话到前台接待处核实客人身份,如有任何疑问,应请客人到前台接待处办理补卡手续。 ⑾前台服务员每班交接时,必须核对客人房卡数量。发现任何缺失必须上报并在交接本上作记录。 ⑿所有房卡上不能贴房号。

酒店房卡管理制度20111231

----------------------------精品word文档值得下载值得拥有---------------------------------------------- ----------------------------------------------------------------------------------------------------------------------------------------- ----- 峨眉天颐温泉度假大饭店 房卡管理制度 一、房卡类别 1、客房房卡分总控卡、领班卡、楼层卡、客人卡。 2、总控卡店级领导、客房相关管理人员持有(董事长、总经理、副总经理、客务总监、客房经理) 3、领班卡由各楼层领办持有 4、楼层卡各楼层员工持有 5、客人卡由前台员工制作 注:若领班卡、楼层卡丢失或损坏,应立即上报部门,采取相应的措施(消磁和补办),前台要有补办记录,以免酒店遭受损失 二、客人卡的管理制度: 1、将客房匙交给客人前,前台员工必须确认客人身份; 2、前台原则上单人房每间只发放一条房匙,双人房根据客人要求可发放两条房匙,并在电脑中注明; 3、客人房卡遗失: 验明客人身份和登记相符→说明规定,向客人收取或从押金中扣除赔偿费(30元)→重新制作l把新的钥匙给客人→通知房务中心→使用管理卡到该房间插一次卡(做消磁处理),确保插卡前使用的钥匙作废。 4、客人钥匙损坏: A.验卡→显示房号和客人所报相同,且在期限内→重新制作l把钥匙给客人,并向客人致歉。 B.如果卡号不能显示或不能验卡→验明客人身份和登记相符→重新制作1把钥匙给客人,并向客人致歉。 5、客人寄存钥匙: A.听清客人所报房号,请客人稍等→验卡→显示房号和客人所报一致,取房卡填写房号,钥匙插入新房卡,放在寄存抽屉内→客人来取时,验明身份后,交还钥匙,将写房号的房卡撕毁。 ----------------------------精品word文档值得下载值得拥有----------------------------------------------

酒店前台房卡管理制度

酒店前台房卡管理制度 酒店前台房卡处理制度一、房卡类别:1、客房房卡分总控卡、工头卡、楼层卡、客人卡。2、总控卡店级领导、客房相关处理人员持有(董事长、总司理、副总司理、客务总监、客房司理)3、工头卡由各楼层领办持有4、楼层卡各楼层职工持有5、客人卡由前台职工制造注:若工头卡、楼层卡丢掉或损坏,应立即上报部分,采纳相应的办法(消磁和补办),前台要有补办记载,避免酒店遭受丢失二、客人卡的处理制度:1、将客房匙交给客人前,前台职工有必要承认客人身份;2、前台原则上单人房每间只发放一条房匙,双人房依据客人要求可发放两条房匙,并在电脑中注明;3、客人房卡丢失:验明客人身份和挂号相符→阐明规则,向客人收取或从押金中扣除赔偿费(30元)→从头制造l把新的钥匙给客人→告诉房务中心→运用处理卡到该房间插一次卡(做消磁处理),保证插卡前运用的钥匙报废。4、客人钥匙损坏:A.验卡→显现房号和客人所报相同,且在期限内→从头制造l 把钥匙给客人,并向客人致歉。B.假如卡号不能显现或不能验卡→验明客人身份和挂号相符→从头制造1把钥匙给客人,并向客人致歉。5、客人存放钥匙: A.听清客人所报房号,请客人稍等→验卡→显现房号和客人所报共同,取房卡填写房号,钥匙刺进新房卡,放在存放抽屉内→客人来取时,验

明身份后,交还钥匙,将写房号的房卡撕毁。B.如验卡时,房号不能显现,应先验明身份,从头制造钥匙,再进行存放。C.如客人存放时吩咐别人来取→填写留言单,请客人签字承认→钥匙、留言单放在房卡中存放于收银抽屉内→收取时验明身份→留言单保留在客帐内直至客人退房。6、客人退房时,前台职工应提示客人交还房匙→如客人出示的钥匙没有房卡或押金单证明其房号,有必要验卡验证无误后,方可告诉客房服务员查房并处理退房手续。7、退房时,客人将钥匙留在房间:客房服务员查完房交到前台。凡有折痕、开裂、显着污迹、坏的钥匙,交前台主管保管。8、未经挂号客人答应,不得为任何来访者敞开客人房间或发卡给来访者;9、任何服务员如发现房卡留传于公共场所,应立即交当值主管,送回前台接待处处理;10、客房服务员不得对客人以错放锁匙在房间内为由,随意开房门让客人进入,应即时打电话到前台接待处核实客人身份,如有任何疑问,应请客人到前台接待处处理补匙手续。11、前台服务员每班交代时,有必要核对客人钥匙数量。发现任何缺失有必要上报并在交代本上作记载。

旅馆治安管理制度

美湖假日酒店治安管理制度 (一) 安全责任制度。 旅馆业的法定代表人或者主要负责人为治安责任人,负责组织本单位员工切实贯彻执行相关法律法规和旅馆业治安管理的各项规章制度;加强对内部保卫组织的领导,教育员工提高警惕,遵纪守法,落实各项安全防范措施。 (二) 验证登记制度。 对入住旅客,要严格检验其有效证件,做到人证相符,登记内容齐全、准确、不漏登、错登,旅馆入住、退宿登记率达到100%。验证主要是查验旅馆客居民身份、军人证、司法机关的释放证明文书、公安机关的身份证明、有身份证号码的其他证件(驾驶证等),以及行政事业单位的工作证件等;查验登记主要包括查验身份证件真伪,登记旅馆姓名、证件号码、户籍住址以及入住时间等项目。 (三) 使用旅馆业治安管理信息系统制度。 1. 及时录入、修改、传送旅馆地址、名称、经营范围等基本情况; 2. 及时录入、修改、传送旅馆法人、负责人、安保部和客房部、前厅部等部门负责人、客房、总台、安保部门的从业人员花名册; 3. 及时录入、传送行李寄存、现金及贵重物品寄存、拾物登记等情况;

4. 及时录入、传送可疑情况报查信息、骚扰登记情况; 5. 及时录入、传送发生的各种治安案件、刑事案件和治安灾害事故的情况,以及系统设置的其他信息; 6. 及时浏览接收各种通知、通缉、通报、协查,并录入、传送接收回执。 7. 因故不能及时录入旅客住宿信息的,要在1小时内补录、传送。交接班时要检查计算机登记的信息,对未传送的录入信息按规定传送。其他相关信息或信息变更要及时录入、即时传送。 8. 建立系统管理使用日志,将每天入退宿人员信息、录入数量和传输情况如实登记。如遇计算机无法录入和传输帮障时,应在30分种内和系统维修单位联系,同时告知当地派出所。 (四) 访客登记制度。 对前来访客的非住宿人员,门卫或前台服务人员应审查登记其身份证件项目、记录会客来去时间,由旅馆工作人员安排会见,提示来访客者遵守访客时间,一般安排在会客室或指定的地点,不宜进入客房会客。 (五) 值班巡查制度。 旅馆应根据规模大小设立专兼职内保人员,负责门卫、内部安全保卫和停车场所等重要部位安全管理。旅馆安保人员要加强对消防安全、治安安全检查,建立安全检查登记簿。按规定应安装监控系统的

星级酒店房卡管理制度

一、房卡类别: 1、客房房卡分总控卡、领班卡、楼层卡、客人卡。 2、总控卡店级领导、客房相关管理人员持有(董事长、总经理、副总经理、客务总监、客房经理) 3、领班卡由各楼层领办持有 4、楼层卡各楼层员工持有 5、客人卡由前台员工制作 注:若领班卡、楼层卡丢失或损坏,应立即上报部门,采取相应的措施(消磁和补办),前台要有补办记录,以免酒店遭受损失 二、客人卡的管理制度: 1、将客房匙交给客人前,前台员工必须确认客人身份; 2、前台原则上单人房每间只发放一条房匙,双人房根据客人要求可发放两条房匙,并在电脑中注明; 3、客人房卡遗失: 验明客人身份和登记相符→说明规定,向客人收取或从押金中扣除赔偿费(30元)→重新制作l把新的钥匙给客人→通知房务

中心→使用管理卡到该房间插一次卡(做消磁处理),确保插卡前使用的钥匙作废。 4、客人钥匙损坏: A.验卡→显示房号和客人所报相同,且在期限内→重新制作l把钥匙给客人,并向客人致歉。 B.如果卡号不能显示或不能验卡→验明客人身份和登记相符→重新制作1把钥匙给客人,并向客人致歉。 5、客人寄存钥匙: A.听清客人所报房号,请客人稍等→验卡→显示房号和客人所报一致,取房卡填写房号,钥匙插入新房卡,放在寄存抽屉内→客人来取时,验明身份后,交还钥匙,将写房号的房卡撕毁。 B.如验卡时,房号不能显示,应先验明身份,重新制作钥匙,再进行寄存。 C.如客人寄存时嘱咐他人来鳃填写留言单,请客人签字确认→钥匙、留言单放在房卡中存放于收银抽屉内→领取时验明身份→留言单保留在客帐内直至客人退房。

6、客人退房时,前台员工应提醒客人交还房匙→如客人出示的钥匙没有房卡或押金单证明其房号,必须验卡验证无误后,方可通知客房服务员查房并办理退房手续。 7、退房时,客人将钥匙留在房间:客房服务员查完房交到前台。凡有折痕、断裂、明显污迹、坏的钥匙,交前台主管保管。 8、未经登记客人许可,不得为任何来访者开启客人房间或发卡给来访者; 9、任何服务员如发现房卡遗留于公共场所,应立即交当值主管,送回前台接待处处理; 10、客房服务员不得对客人以错放锁匙在房间内为由,随便开房门让客人进入,应即时打电话到前台接待处核实客人身份,如有任何疑问,应请客人到前台接待处办理补匙手续。 11、前台服务员每班交接时,必须核对客人钥匙数量。发现任何缺失必须上报并在交接本上作记录。 10、所有IC卡上不能贴房号。