Effect-of-post-weld-heat

Technical Report

Effect of post-weld heat treatments on microstructure and mechanical properties of friction welded alloy 718

joints

R.Damodaram,S.Ganesh Sundara Raman ?,K.Prasad Rao

Department of Metallurgical and Materials Engineering,Indian Institute of Technology Madras,Chennai 600036,India

a r t i c l e i n f o Article history:

Received 21March 2013Accepted 29July 2013

Available online 6August 2013

a b s t r a c t

The effect of post-weld heat treatments on the microstructure and mechanical properties of friction welded joints of alloy 718was studied in the present work.Alloy 718rods were friction welded with two prior heat treatments –solution treatment and solution treatment and aging.Solution treatment was done at 995°C for 1h.Aging was done at 720°C for 8h followed by furnace cooling to 620°C and holding at 620°C for 8h followed by air cooling.After friction welding,the joint samples were subjected to two types of post-weld heat treatments –direct aging (aging after welding,the same aging treatment mentioned above)and solution treatment and aging.Electron back scattered diffraction technique and transmission electron microscopy were used to study the development of microstructure.Hardness and tensile properties of the weld joints were evaluated.In the as-welded condition,samples welded with prior solution treatment and aging condition exhibited lower hardness at the weld zone and inferior tensile properties compared to the base material due to the dissolution of strengthening precipitates in the weld zone.On the other hand,formation of ?ne grains due to dynamic recrystallization led to higher hardness at the weld zone compared to the base material welded with prior solution treatment condition.Solution treatment and aging post-weld heat treatment resulted in an abnormal grain growth in the weld zone and thermomechanically affected zone.Owing to the formation of strengthening precipitates,solu-tion treatment and aging post-weld heat treatment resulted in a signi?cant increase in tensile strength of joint samples compared to that of as-welded friction weld joints.However,solution treatment and aging post-weld heat treatment done on friction weld joint samples with prior solution treatment or solution treatment and aging heat treatment condition resulted in inferior tensile properties compared to those of samples subjected to direct aging post-weld heat treatment.This may be attributed to grain coarsening that occurred during the post-weld solution treatment.Therefore,direct aging after welding is the recom-mended post-weld heat treatment for friction welded alloy 718joints as compared to solution treatment and aging after welding.

ó2013Elsevier Ltd.All rights reserved.

1.Introduction

Alloy 718is a c 00(Ni 3Nb)strengthened Ni–Fe based superalloy that exhibits excellent corrosion resistance and outstanding strength at elevated temperatures.Alloy 718is commonly welded using fusion welding techniques such as tungsten inert gas weld-ing,electron beam welding,and laser welding [1].However,there are problems associated with fusion welding of alloy 718such as the formation of Laves phase,Niobium segregation,micro?ssuring,which could occur in the fusion zone or heat affected zone (HAZ),and affect the mechanical properties and service life [2–6].Appli-cation of a solid state welding process like friction welding could be an alternative joining method to overcome these problems.Friction welding has been commercially used in joining of aero engine components,such as turbine blade –disk (blisk)assemblies,compressor wheel,compressor rotor,and rotor drum [7,8].During friction welding process,the material at the weld zone,thermome-chanically affected zone (TMAZ)and HAZ undergoes changes in temperature,gradient of strain,strain rate and microstructure.Friction weld zone,in general,consists of very ?ne grains due to the occurrence of dynamic recrystallization during the process [9].Wang et al.[10]reported an average grain size of 2–5l m in friction weld zone of alloy 718.

As the temperatures experienced during friction welding are above the solvus temperatures of the strengthening precipitates,dissolution of the precipitates can occur in the weld zone and TMAZ/HAZ.Post-weld heat treatment is hence recommended to regain the mechanical properties of alloy in the weld zone.Wang et al.[11]observed no change in the ?ne grain microstructure of weld zone after post-weld solution treatment at 1050°C followed by aging treatment.Daus et al.[12]observed a reduction in hard-ness value in the weld zone compared to base material due to dis-solution of c 00precipitates and loss in hardness could be recovered

0261-3069/$-see front matter ó2013Elsevier Ltd.All rights reserved.https://www.sodocs.net/doc/5117152790.html,/10.1016/j.matdes.2013.07.091

Corresponding author.Tel.:+914422574768;fax:+914422570509.

E-mail address:ganesh@iitm.ac.in (S.Ganesh Sundara Raman).

after a post-weld heat treatment (PWHT)due to reprecipitation of c 00and c 0precipitates in RR 1000(Ni-based super alloy)to Inconel 718inertia friction weld zone.Huang et al.[13]reported that pre-cipitate coarsening and reduction in strength depend on holding time during PWHT of inertia friction welded Alloy 720Li to Inconel 718.Kim et al.[14]observed improvement in the mechanical prop-erties after PWHT for 8h on friction welded alloy 718and SNCrW stainless steel (in wt%0.2C,1.4Si,19.8Cr,9.5Ni and 68.3Fe)due to the formation of c 00strengthening precipitate.

In our previous work [15],we reported the microstructure and mechanical properties of friction welded alloy 718joints in the as-welded and post-weld direct aged conditions.Samples welded in prior solution treatment followed by aging (STA)condition exhib-ited lower hardness at the weld interface compared to the base material in STA condition due to the dissolution of strengthening precipitates.After post-weld aging,a signi?cant increase in hard-ness was observed in the weld zone for samples welded in STA and solution treatment conditions.The present work was under-taken to study the effect of post-weld STA treatment on micro-structure and mechanical properties of friction welded alloy 718

joints.The results were compared with those of welds subjected direct aging treatment.

2.Experimental details

The chemical composition (in wt%)of base material alloy 718used in the present study was 51.6Ni,18.2Cr,5.1Nb,3.28Mo,1.06Ti,0.56Al,0.33V,0.09Mn,0.01S,0.004C,0.003B and 19.763Fe.Alloy 718rods of 13mm diameter were subjected to two different heat treatment conditions prior to welding:(i)solu-tion treatment (ST)and (ii)STA.Solution treatment was carried out at 995°C for 1h and aging was done at 720°C for 8h followed by furnace cooling to 620°C and then aging at 620°C for 8h followed by air cooling to room temperature.A furnace with a programma-ble controller was used for the heat treatment.The temperature was measured in the furnace chamber.The difference between the measured temperature and the actual sample temperature was within ±3°C.The average cooling rate achieved in the furnace was 2°C/min.

A continuous drive rotary friction welding machine was used for welding.Weld parameters used were as follows:friction pres-sure of 300MPa,upset pressure of 600MPa,burn off length of 4mm and speed of 1500rpm.These parameters were chosen after a number of trial experiments were done with parameters varying in the following range –friction pressure between 200and

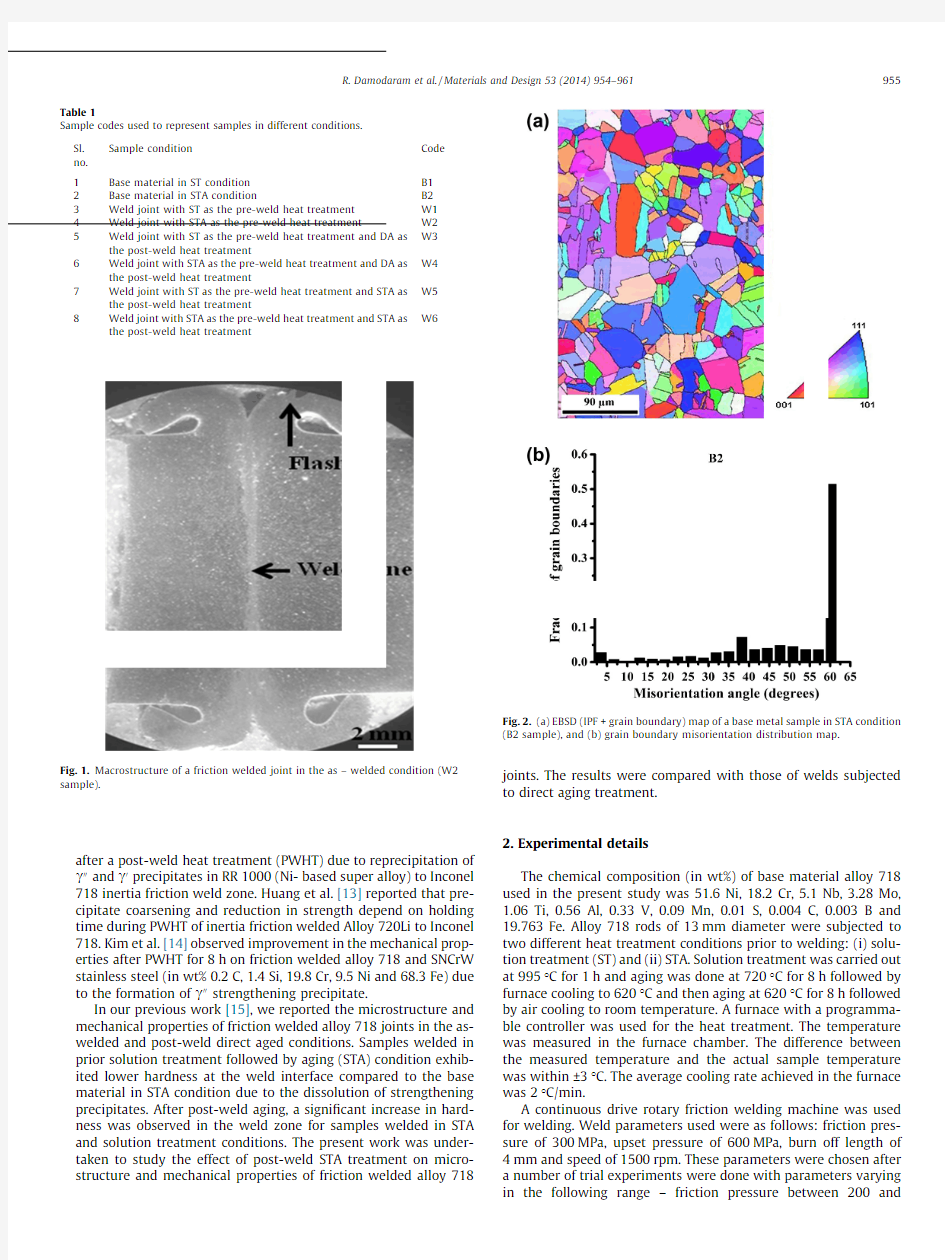

Macrostructure of a friction welded joint in the as –welded condition 2.(a)EBSD (IPF +grain boundary)map of a base metal sample in STA condition sample),and (b)grain boundary misorientation distribution map.

MPa,upset pressure between 300and 600MPa and burn length between 2and 4mm.The parameters,which produced relatively uniform and narrow weld region,were used to produce weld joint samples for the present study.Friction weld joint spec-imens were subjected to two different PWHTs –(i)direct aging (DA)(the same aging treatment mentioned above)and (ii)STA.

Fig.3.EBSD (IPF +grain boundary)map of a W2sample showing weld zone and TMAZ.

4.(a)EBSD (IPF +grain boundary)map of weld zone of a W2sample,and grain boundary misorientation distribution map.

5.(a)EBSD (IPF +grain boundary)map of TMAZ of a W2sample,and (b)grain boundary misorientation distribution map.

6.(a)EBSD (IPF +grain boundary)map of HAZ of a W2sample,and (b)grain boundary misorientation distribution map.

7.Transmission electron micrograph of weld zone of a W2sample showing grains.

Post-weld solution treatment was carried out at 995°C due to the following reasons.It is the solvus temperature of d phase,to relieve residual stress,to get homogenized microstructure and to improve the mechanical properties [16].Table 1shows the codes used to represent samples in different pre-and post-weld heat treatment conditions.

Samples for electron back scattered diffraction (EBSD)analysis were polished as per standard metallographic practices followed by ?ne polishing with colloidal silica.EBSD measurement was car-ried out by using FEI Quanta 200scanning electron microscope (SEM)equipped with TSL–OIM software at a step size of 0.6l m.For transmission electron microscopic observations,specimens were polished to a thickness of 100l m and subjected to twin jet electro polishing with an electrolyte of 10%perchloric acid in methanol at à30°C.Vickers microhardness measurements were made across weld line with a load of 0.5kg and dwell time of 15s.Room temperature tensile tests were carried out as per ASTM:E8/E8M-11standard specimen con?guration.Fracture surfaces of tensile tested samples were observed using an SEM.

3.Results and discussion 3.1.Characterization

The macrostructure of the friction welded alloy 718joint (with STA as the pre-weld heat treatment)in the as-welded condition (W2sample)is shown in Fig.1.The weld zone produced was rela-tively uniform and narrow throughout the entire cross section.To understand the microstructural changes during friction welding,EBSD technique provides quantitative measurement of the fraction of high and low angle grain boundaries and average grain size.The EBSD (Inverse Pole Figure (IPF)+grain boundaries)map of the base material in STA condition (B2sample)is shown in Fig.2(a).It shows equi-axed grains and annealing twin boundaries with an average grain size of 29l m.More than 90%of the grain boundaries were high angle grain boundaries (misorientation angle >15°)as shown in Fig 2(b).

Fig.3shows weld zone and TMAZ of a W2sample.Weld zone microstructure of a W2sample consists of new equi-axed recrys-tallized grains with an average grain size of 4–5l m (Fig.4(a)).Weld zone consists of around 68%high angle grain boundaries along with 32%low angle grain boundaries (angle <15°misorienta-tion)(Fig.4(b)).The temperature at the weld zone during friction welding was measured by an infrared thermometer and the peak temperature was 1118°C [15].Yang et al.[17]modeled inertia welding of IN 718and calculated the strain rate to be 250s à1for an upset pressure of 250MPa at 1260°C.Srinivasan and Prasad [18]developed processing maps for hot working of IN 718.They re-ported the presence of two domains of dynamic recrystallization –one occurring at 950°C and 0.001s à1and the other at 1200°C and 0.1s à1.They suggested that the dynamic recrystallization in the former domain is nucleated by d (Ni 3Nb)precipitates leading to ?ne grained microstructure.In the second domain,the availability of interstitial carbon atoms (due to dissolution of carbides in the matrix)increases the rate of dislocation generation and so dynamic recrystallization occurs.In a study on hot compression behavior of alloy 718,Wang et al.[19]reported the occurrence of dynamic recrystallization during deformation of parent grain boundaries,which occurs due to subgrain rotation or by formation of twinning.The sub grain rotation leads to grain boundary shearing resulting in the formation of local orientation and strain gradient,which leads to the dynamic recrystallized grains.Metals with low or intermediate stacking fault energy (copper,nickel,stainless steel)have very slow recovery and dynamic recrystallization occurs when critical dislocation density and critical strain are achieved

Transmission electron micrograph of TMAZ of a W2sample formation of ?ne grains along the deformed grain boundaries.

Bright ?eld transmission electron micrograph showing c 00precipitates zone of a W6sample.

10.(a)EBSD (IPF +grain boundary)map of base material portion of a sample,and (b)grain boundary misorientation distribution map.

and Design 53(2014)954–961957

Fig.11.EBSD(IPF+grain boundary)map of a W6sample showing weld zone and TMAZ.

12.(a)EBSD(IPF+grain boundary)map of a W6sample showing weld

(b)grain boundary misorientation distribution map.

Fig.13.Grain size distribution in weld zone of W2and W6samples.

14.(a)EBSD(IPF+grain boundary)map of TMAZ in a W6sample,and(b)grain boundary misorientation distribution map.

15.Microhardness pro?les obtained across the weld joints in different conditions.

[20].TMAZ undergoes relatively lower amount of strain and tem-perature compared to weld zone.Serrated,deformed grain bound-aries and?ne grains around the original deformed grains were observed in TMAZ of a W2sample(Fig.5(a)).TMAZ shows around STA PWHT condition(W6)is shown Fig.13.Recrystallization oc-curs in the deformed material due to the formation and migration of high angle grain boundaries,driven by the stored energy of deformation[24].Driving force for the abnormal grain growth arises by decreased stored energy.Important factors that promote

Table2

Average values of grain size and diagonal size of the indentations in case of two samples(W2and W6).

Sample Weld zone TMAZ Base material

Grain size(l m)Diagonal size(l m)Grain size(l m)Diagonal size(l m)Grain size(l m)Diagonal size(l m)

W2 4.551.25055.129.048.1

W627.045.74148.033.046.8

Table3

16.Appearance of fracture surface of tensile tested samples:(a)W5sample,

(b)W6sample.

R.Damodaram et al./Materials and Design53(2014)954–961959

abnormal grain growth are temperature,solutes and particles, specimen size and texture[20].In the as-welded condition,TMAZ showed necklace like microstructure(W2sample).However after PWHT,grains in the TMAZ became coarse and equi-axed with an average grain size of41l m(as shown in Fig.14(a))with around 86%high angle boundaries and twins(as shown Fig.14(b)).Only few grains were scanned due to coarse grain microstructure.Over all,the post-weld solution treatment was found to have a signi?-cant effect on weld zone,TMAZ and base material microstructures.

3.2.Microhardness

The microhardness pro?les across the weld interface in friction weld joints in different conditions are shown in Fig.15.In the as-welded condition,samples welded in STA condition(W2samples) exhibited lower hardness at the weld zone compared to the base material due to the dissolution of strengthening precipitates in the weld zone.On the other hand,in case of samples welded in ST condition(W1samples),formation of?ne grains due to dy-namic recrystallization led to higher hardness at the weld zone compared to the base material.After post-weld STA treatment, friction weld joint specimens(W5and W6samples)showed an in-crease in the hardness in all zones compared to that in the as-welded condition(W1and W2samples).The increase in the hard-ness at the weld zone is due to dynamic recrystallization during friction welding and formation of strengthening precipitates dur-ing PWHT.Post-weld solution treatment and aging produced lower hardness values in the weld zone and TMAZ(W5and W6samples) when compared to post-weld direct aging treatment(W3and W4 samples).This is due to abnormal grain growth that occurred in the weld zone and TMAZ.There is no signi?cant change in the base material hardness values.Friction weld samples with prior ST or STA heat treatment conditions exhibited similar hardness pro?le after post-weld STA treatment.

In case of W2samples(weld joint with STA as the pre-weld heat treatment),?ner grains formed at the weld zone due to dynamic recrystallization.The grain size of the base material portion of W2sample is29l m,which is coarser than the grain size of the weld zone(4.5l m).However,due to the dissolution of strengthen-ing precipitates,the hardness of weld zone decreased.As the base material portion did not experience higher temperature as experi-enced by the weld zone,there was no dissolution of the strength-ening precipitates and so the hardness was much higher (indentation size was smaller in the base material compared to that in the weld zone–see Table2).In case of W6samples,there is not much difference between the grain size of the weld zone and that of the base material.It may be noted that strengthening pre-cipitates formed in the weld zone during the post-weld STA treat-ment.So there was not much difference between the hardness values of weld zone and base material.

3.3.Tensile properties

The weld joint tensile samples in PWHT condition failed in the base material far away from the weld zone.Post-weld STA treat-ment(W5and W6samples)resulted in a signi?cant increase in the yield strength and ultimate tensile strength compared with the as-welded condition(W1and W2samples)–see Table3.This could be due to the formation of strengthening precipitates and grain re?nement.However,post-weld STA samples with prior ST or STA heat treatment conditions(W5and W6samples)exhibited inferior tensile strength and%elongation compared to base mate-rial in STA condition(B2samples)and samples subjected to post-weld direct aging(W3and W4samples).This may be attributed to grain coarsening that occurred in the post-weld solution treat-ment.Cao et al.[25]observed that post-weld STA treatment re-sulted in a slight decrease in ultimate tensile strength of base material due to grain coarsening in laser welding of Inconel718. The base material in ST condition(B1samples)exhibited the high-est%elongation.This may be due to dissolution of strengthening precipitates in the matrix.After post-weld STA treatment,samples (W5and W6samples)showed reduction in ductility due to forma-tion of strengthening precipitates in the matrix.SEM examination of fracture surfaces of tensile tested samples showed dimples indi-cating ductile mode of failure(Fig.16).

4.Conclusions

Based on the results obtained in the present investigation on the effect of post-weld heat treatments on the microstructure and mechanical properties of friction welded joints of alloy718, the following conclusions are drawn.

(1)The as-welded friction weld zone of alloy718(with prior

solution treatment and aging condition)exhibited new equi-axed recrystallized grains with an average grain size of4–5l m.Fine grains around the original deformed grains were observed in thermomechanically affected zone,which experienced relatively lower strain and temperature com-pared to weld zone.

(2)Post-weld solution treatment and aging resulted in a signif-

icant increase in grain size from4l m to27l m at the weld zone.Thermomechanically affected zone became coarse and equi-axed with an average grain size of41l m.The average grain size of the base material portion of the joint after the post–weld solution treatment and aging treatment was 33l m.

(3)Solution treatment and aging post-weld heat treatment

resulted in an abnormal grain growth in the weld zone and thermomechanically affected zone.Owing to the formation of strengthening precipitates,solution treatment and aging post-weld heat treatment resulted in a signi?cant increase in tensile strength of joint samples compared to that of as-welded friction weld joints.However,solution treatment and aging post-weld heat treatment done on friction weld joint samples with prior solution treatment or solution treatment and aging heat treatment condition resulted in inferior tensile properties compared to those of samples sub-jected to direct aging post-weld heat treatment.This may be attributed to grain coarsening that occurred during the post-weld solution treatment.

(4)Compared to post-weld solution treatment and aging,post-

weld direct aging treatment is recommended to restore microstructure and mechanical properties.

References

[1]Lingenfelter.Welding of Inconel718:a historical overview.In:Loria EA,editor.

Conference proceedings on superalloy718–metallurgy and applications.

TMS-AIME.Warrendale;1989.p.673–83.

[2]Richards NL,Huang X,Chaturvedi MC.Heat affected zone cracking in cast

Inconel718.Mater Charact1992;28:179–87.

[3]Huang X,Chaturvedi MC,Richards NL,Jackman J.The effect of grain boundary

segregation of boron in cast alloy718on HAZ micro?ssuring–a SIMS analysis.

Acta Mater1997;45:3095–107.

[4]Janaki Ram GD,Venugopal Reddy A,Prasad Rao K,Reddy GM,Sarin Sundar JK.

Microstructure and tensile properties of Inconel718pulsed Nd–YAG laser welds.J Mater Proces Technol2005;167:73–82.

[5]Sivaprasad K,Ganesh Sundara Raman S,Mastanaiah P,Madhusudhan Reddy G.

In?uence of magnetic arc oscillation and current pulsing on microstructure and high temperature tensile strength of alloy718TIG weldments.Mater Sci Eng A2006;428:327–31.

[6]Sivaprasad K,Ganesh Sundara Raman S.In?uence of magnetic arc oscillation

and current pulsing on fatigue behavior of alloy718TIG weldments.Mater Sci Eng A2007;448:120–7.

960R.Damodaram et al./Materials and Design53(2014)954–961

[7]Schwartz MM.Metals joining https://www.sodocs.net/doc/5117152790.html,A:McGraw-Hill,Inc.;1979.

[8]Roder O,Albrecht J,Lütjering G.Microstructure and mechanical properties of

an inertia friction welded INCOLOY alloy909-Inconel alloy718joint for rotating applications.Mater High Temp2006;23:171–7.

[9]Maalekian M.Review friction welding–critical assessment of literature.Sci

Technol Weld Join2007;12:738–59.

[10]Wang H,Ikeuchi K,Takahashi M,Ikeda A.Microstructures forming in friction

welding of Inconel718alloy–joint performance and its controlling factors in friction welding of Inconel718alloy.Weld Int2009;23:670–8.

[11]Wang H,Ikeuchi K,Takahashi M,Ikeda A.Joint strength of Inconel718alloy

and its improvement by post-weld heat treatment-joint performance and its controlling factors in friction welding of Inconel718alloy.Weld Int 2009;23:679–86.

[12]Daus F,Li HY,Baxter G,Bray S,Bowen P.Mechanical and microstructural

assessment of RR1000to IN718inertia welds–effects of welding parameters.

Mater Sci Technol2007;23:1424–32.

[13]Huang ZW,Li HY,Preuss M,Karadge M,Bowen P,Bray S,et al.Inertia friction

welding dissimilar nickel-based super alloys720Li to IN718.Metall Mater Trans A2007;38A:1608–20.

[14]Kim NY,Kim JH,Kong YS,Yoon JW,Yeom JT,Lee,et al.The effect of postweld

heat treatment on mechanical properties of friction welded–alloy718and SNCRW stainless steels.Adv Mat Res2007;26–28:511–4.

[15]Damodaram R,Ganesh Sundara Raman S,Prasad Rao K.Microstructure and

mechanical properties of friction welded alloy718.Mater Sci Eng A 2013;560:781–6.[16]Kuo Sindo.Welding metallurgy.2nd https://www.sodocs.net/doc/5117152790.html,A:John Wiley&Sons Inc;2003.

[17]Yang LB,Gebelin JC,Reed RC.Modelling of inertia welding of IN718super

alloy.Mater Sci Technol2011;27:1249–63.

[18]Srinivasan N,Prasad YVRK.Microstructural control in hot working of IN-718

superalloy using processing map.Metall Mater Trans A1994;25A:2275–84.

[19]Wang Y,Shao WZ,Zhen L,Zhang XM.Microstructure evolution during

dynamic recrystallization hot deformed super alloy718.Mater Sci Eng A 2008;486:321–32.

[20]Humphreys FJ,Hatherly M.Recrystallization and related annealing

phenomena.2nd ed.Oxford,UK:Elsevier Sciences Ltd.;2004.

[21]Zhou LX,Baker TN.Effect of strain rate and temperature on IN718during high

temperature deformation.Mater Sci Eng A1994;177:1–9.

[22]Fukumoto S,Yamamoto D,Tomita T,Okita K,Tsubakino H,Yamamoto A.Effect

of post-weld heat treatment on microstructure and mechanical properties of AZ31B friction welded joint.Mater Trans2007;48:44–52.

[23]Hu Zhili,Yuan Shijian,Wang Xiaosong,Liu Gang,Huang Yongxian.Effect of

post-weld heat treatment on the microstructure and plastic deformation behavior of friction stir welded2024.Mater Des2011;32:5055–60.

[24]Doherty RD,Hughes DA,Humphreys FJ,Jonas JJ,Juul Jensen D,Kassner ME,

et al.Current issues in recrystallization.Mater Sci Eng A1997;238:219–74.

[25]Cao X,Rivaux B,Jahazi M,Cuddy J,Birur A.Effect of pre-and post-weld heat

treatment on metallurgical and tensile properties of Inconel718alloy butt joints welded using4kW Nd:YAG laser.J Mater Sci2009;44:4557–71.

R.Damodaram et al./Materials and Design53(2014)954–961961