Modeling the Bauschinger effect for sheet metals, part I theory

Modeling the Bauschinger e?ect for sheet

metals,part I:theory

B.K.Chun a ,J.T.Jinn a ,J.K.Lee b,*

a

Scienti?c Forming Technologies Corporation,5038Reed Rd.,Columbus,OH 43220,USA b The Ohio State University,Department of Mechanical Engineering,206West 18th Avenue,Columbus,

OH 43210,USA

Received in ?nal revised form 10July 2001Abstract

It is essential to model the Bauschinger e?ect correctly for sheet metal forming process simulation and subsequent springback prediction when material points are subjected to cyclic loading conditions.The combined nonlinear hardening model for time independent cyclic plasticity,proposed by Chaboche and co-workers,is examined and a simple modi?cation is suggested for the isotropic part of the hardening rule to utilize the conventional tensile test data directly.This modi?cation is useful for the materials whose reverse loading curves satu-rate to the monotonic loading curve.In addition,an anisotropic nonlinear kinematic hard-ening model (ANK model)is proposed in an attempt to represent the Bauschinger e?ect more realistically.Possible o?set in ?ow stress is modeled by treating the back stress evolution during reverse loading di?erently from the initial loading.This strategy coupled with the modi?ed isotropic hardening rule seems to provide a way to model the Bauschinger e?ect consistently over multiple cycles.Two types of auto-body alloys are examined in this paper.Associated material parameters are determined by employing available tension-compression test data and multi-cycle bend test data.A developed ?nite element formulation is applied to analyze simple validation type of problems.The cyclic stress–strain curves generated from the proposed ANK model match remarkably well with measured data.#2002Elsevier Science Ltd.All rights reserved.

Keywords:A.Sheet metal forming;B.Cyclic loading;B.Constitutive behavior;C.Finite elements;C.Hardening parameter

identi?cation

International Journal of Plasticity 18(2002)571–595

https://www.sodocs.net/doc/604106032.html,/locate/ijplas

0749-6419/02/$-see front matter #2002Elsevier Science Ltd.All rights reserved.

P I I:S 0749-6419(01)00046-8

*Corresponding author.Tel.:+1-614-292-7371;fax:+1-614-292-3163.

E-mail address:lee.71@https://www.sodocs.net/doc/604106032.html, (J.K.Lee).

1.Introduction

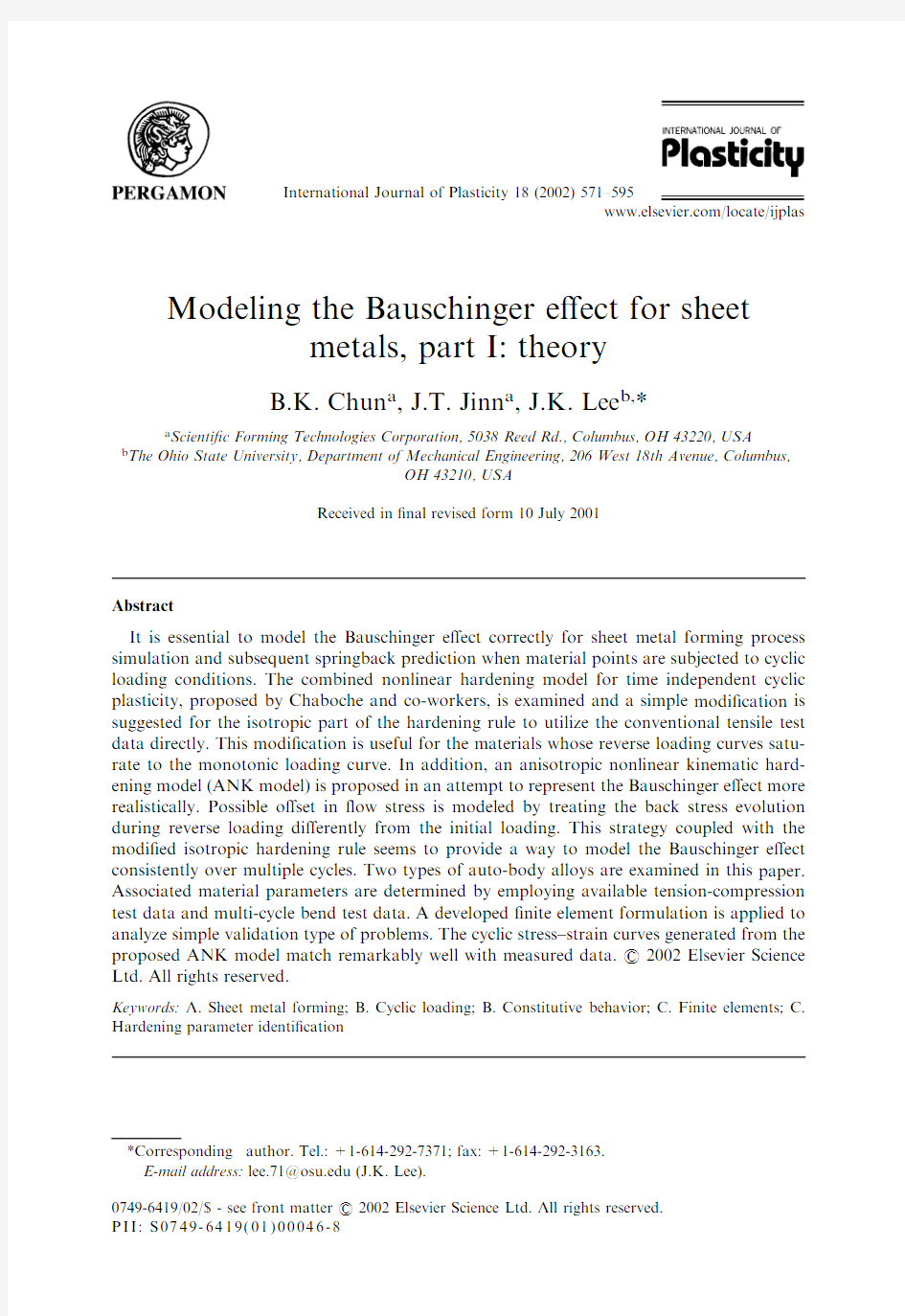

In a typical sheet metal forming practice,material points may experience cyclic loads;for example,bending–unbending on the die shoulder and reverse bending-unbending at the punch.In this case,transient cyclic behavior of the material must be modeled properly for a realistic simulation of the sheet metal forming process and subsequent springback prediction.Stress–strain curves similar to Fig.1are commonly observed during tension–compression (or reverse yield)tests of some alloys (Wilson and Bate,1983;Bate and Wilson,1986;Christodoulou et al.,1986;Balakrishnan,1999;Miller et al.,1999).As schematically shown in Fig.1,reversal loading curve may not saturate to the monotonic loading curve,leaving a permanent o?set in addition to a reduction in subsequent yield stress.It is generally believed (Sowerby and Uko,1979;Bate and Wilson,1986;Takahashi and Shiono,1991;Tan et al.,1994;Khan and Huang,1995)that the following three basic requirements must be addressed to model the Bauschinger e?ect

properly:

Fig.1.Schematic Bauschinger curve with a permanent softening,á ?f e"

"P ;""P ?

T(the reverse loading curve AB is inverted so that the magnitude of the reverse ?ow stress becomes a function of the accumu-

lated equivalent plastic strain ""p ).572 B.K.Chun et al./International Journal of Plasticity 18(2002)571–595

1.Correct non-linearity of stress–strain loop

2.Reduced elastic limit at reversal straining

3.Permanent o?set for some materials

Prager (1949,1956)and Ziegler (1959)initiated some fundamental frame-work for kinematic hardening rules.Major di?erence of two models comes from the direction of the translation of the center of the yield surface.Both linear kinematic hardening models can only provide rough approximations to the Bauschinger e?ect with a single constant hardening modulus.From the experimental observations,many authors (Drucker and Palgen,1981;Dafalias,1984;Lemaitre and Chaboche,1990)conclude that the correct nonlinearity of stress–strain loop is important to describe the hardening behavior of metals under cyclic loading.Mroz (1967)introduced the concept of a ‘‘?eld of work hardening moduli’’and generalized the linear model,which led to multi-surface model (Mroz,1967,1981).Two surface models (Dafalias and Popov,1975,1976;Tseng and Lee,1983;McDowell,1985a,b,1987,1989)have been proposed to remedy the di?culties associated with the large number of surfaces necessary to describe the hardening.Recently,nonlinear kinematic hardening models of Armstrong and Frederick (1966)type have gained some popularity (Chaboche,1977,1986,1989;Chaboche et al.,1979;Chaboche and Rousselier,1981,1983;Ohno and Kachi,1986;Lemaitre and Chaboche,1990;Ohno and Wang,1993a,1993b;Jiang and Kurath,1996;Wang and Barkley,1998,1999;Adbel and Ohno,2000).These models capture nonlinear hardening behavior and smooth transition from elastic to plastic deformation relatively well.However,they all have a common characteristic of generating reversal ?ow stress curves that saturate to the monotonic loading curve,thereby having di?culties to model a possible o?set in ?ow stress when the load is reversed.Recent development and associated theories are well documented by Chaboche (1986),Lemaitre and Chaboche (1990),and Khan and Huang (1995).Geng and Wagoner (2000)generalized the nonlinear kinematic hardening model of Armstrong and Frederick (1966)type by introducing an independent evolution of the bounding surface to capture a permanent o?set.Wagoner and co-workers (Geng,2000;Geng and Wagoner,2000,2001;Geng et al.,2001)also examined sev-eral interesting loading and reversal loading cases by utilizing the proposed model along with tension–compression test data for automotive alloys.The Geng–Wag-oner model requires the following parameters:

.Ratio (m )of the kinematic response (translation)to the isotropic response

(expansion)of the bounding surface,which can be a function of the deformation.

.Plastic moduli for continuous loading (H P c )and reverse loading (H P r )as func-

tions of accumulated equivalent plastic strain.

These material parameters are calibrated from tension-compression (T-C)and compression–tension (C-T)test data in their studies.The choice of m and H P r appears to be somewhat fuzzy and yet plays a critical role to the overall performance of the model.Since it is not practical to perform tension-compression tests over the entire range of expected pre-strains before a reversal in loading,an assumption (or an extrapolation)has to be made for H P r beyond the tested pre-strain range.Fur-

B.K.Chun et al./International Journal of Plasticity 18(2002)571–595573

thermore,the smooth transition requirement will be violated when H P

r is assumed to

approach zero as the pre-strain increases over the tested range.While the Geng–Wagoner model appears to have all ingredients to model the Bauschinger e?ect accurately,further studies will be necessary for a judicious choice of material para-meters and for applications to multi-cyclic loading cases.

As an alternative to the Geng–Wagoner model,a reasonably simple anisotropic nonlinear kinematic hardening model(ANK model)is proposed in this paper,which satis?es all three basic requirements to model the Bauschinger e?ect consistently over multiple cycles.A modi?cation to the isotropic part of the Chaboche model (Chaboche,1977,1986,1989;Chaboche et al.,1979;Chaboche and Rousselier, 1981,1983;Lemaitre and Chaboche,1990)is?rst suggested for a better?t to the conventional tensile data.The permanent o?set in reverse?ow stress is treated by di?erent evolution rules for the back-stress during a reversal loading and the monotonic loading.Table1summarizes a comparison of ANK model with other generic models,in terms of the three basic requirements.

The associated?ow rule with Hill’s1948anisotropic yield criterion(Hill,1950)is used in this investigation.The?ow potential under the plane stress condition can be expressed in terms of the true objective stress and back-stress as,

f?1

2

e à TTáPáe à Tà o

eT2?0e1T

where o is an equivalent true stress representing the current yield surface size and

P?2

1à 120

à 12 220

00 66

2

4

3

5; ?

xx

yy

xy

8

<

:

9

=

;; ?

xx

yy

xy

8

<

:

9

=

;e2aT

The coe?cients in P can be related to the R-values as(Valliappan,1976;Li,1996):

12?

R0

0; 66?

R0tR90

eT1t2R45

eT

900

;

22? 12t 23; 23?

R0

R901tR0

eT

:

e2bT

Table1

Representation of Bauschinger e?ect

Material models Bauschinger e?ect

Reduced elastic limit at reversal straining Correct non-linearity of

stress–strain loop

Permanent

softening

Linear kinematic hardening Yes No Yes Nonlinear kinematic hardening Yes Yes No ANK Yes Yes Yes 574 B.K.Chun et al./International Journal of Plasticity18(2002)571–595

True stress and natural strain are used through out the investigation.

2.Chaboche model and suggested modi?cation to the isotropic part

The Chaboche model has gained some popularity and has been implemented into several commercial ?nite element packages in recent years.The back stress vector is assumed to be a sum of the Nk vector components,

?X Nk i ?1 i

e3T

Each component of the back stress is assumed to evolve independently as in Arm-strong and Frederick (1966),type

:i ?C i o e à T"":p à i i "":p e4T

where C i and i are material parameters which can be obtained from cyclic testing.The i term determines the rate at which the saturation value of kinematic hardening decreases with increasing plastic deformation.In the formulation of this type,the saturation of back stress at a reversal loading is same as the monotonic initial loading,if C i and i are constants.

The Chaboche model uses a special function for the isotropic response (expansion of the yield surface):

o ? o tR

e5a TR ?

X Ni i ?1R i e5b T

R :i ?b i eQ i àR i T"":p e5c T

where o represents the initial yield stress and "

":P is rate of accumulated equivalent plastic strain.R is the change of yield surface size governed by the Ni functions,and Q i and b i are material parameters.It is believed that the saturation of yield surface expansion is essential for stabilization in cyclic plasticity (Lemaitre and Chaboche,1990).

Integrating Eq.(5c)under the uniaxial condition with the initial condition R i ?0produces,

R i ?Q i e1àe àb i ""p Twith Q i àR i 50e6T

B.K.Chun et al./International Journal of Plasticity 18(2002)571–595575

Eq.(6)states that the expansion rate of the active yield surface always decreases monotonically,which generates a convex curve for stable materials.This may lead to erroneous ?tting results for some materials that show upper and lower yields or relatively ?at stress-strain curve.To overcome this restriction,Shen (1999)has employed a tensile curve into the isotropic hardening part to analyze bend/reverse bend tests.An exponential function similar to (6)is suggested to curve ?t a tensile data e tensile Tin this paper:

tensile ? o tK e1àe àN ""p Te7T

which is also equal to the total stress o tR t .Hence,the change in the yield surface size can be expressed as

R ?K e1àe àN ""p Tà ; ?X

Nk i ?1 i e8a T

R :?KN e àN ""p "

":p àX Nk i ?1 :i ; :i ?C i "":p à i i "":p e8b T

Here,K and N are curve ?tting parameters and i is a scalar version of the back stress for the uniaxial loading condition.Hence the material parameters to be determined are C i and i after the curve ?t.

For a uniaxial tensile data e tensile Twith Nk =1and Ni =1,the Chaboche model can be written as

tensile ? o tR t

e9a TR ?R Chaboche ?Q e1àe b ""p Twith Q àR 50e9b T

?C e1àe à "

"p Twith C

à 50e9c TThe single component form (Nk =1and Ni =1)of isotropic hardening rule can be modi?ed as,when (9c)is introduced in (8a),

R ?R Mod ?K e1àe àN ""p TàC e1àe à "

"p Twith C à 50e10T

If the kinematic shift is zero (C =0),the two functions R Chaboche and R Mod are the same with Q =K and b =N .Fig.2compares generated stress–strain curves with a ?ctitious tensile data having the same kinematic hardening rule (C =3Gpa, =200).Note that the Chaboche model for stable materials always produces a convex curve for R because Q àR 50even if more terms are taken (i.e.Ni >1and Nk >1)in the evolution equation.This feature a?ects directly the representation of the ten-

576 B.K.Chun et al./International Journal of Plasticity 18(2002)571–595

sile curve.The suggested modi?cation of isotropic hardening part,Eq.(10)is cap-able of ?tting the tensile curve almost perfectly as shown in Fig.2.This modi?ca-tion to the isotropic response can be combined with the nonlinear kinematic hardening rule of Chaboche,Eqs.(3)and (4)with Nk =Ni =1,which is referred to as Modi?ed Chaboche model in this paper.It is noted that this model is not capable of reproducing a permanent softening even if a linear kine-matic hardening term is added to Eq.(10).Therefore this modi?cation is useful for the materials whose reverse loading curves always saturate to the monotonic loading curve.

3.Proposed anisotropic hardening model and o?set in reverse ?ow stress

Referring to Fig.1and based on experimental observations (Wilson and Bate,1983;Bate and Wilson,1986;Christodoulou et al.,1986;Balakrishnan,1999;Miller et al.,1999),the o?set in reversal ?ow stress can be viewed as a function of accu-mulated plastic strain and pre-strain;

á ?f e"

"p ;""p ?Te11Twhere "

"p is the accumulated equivalent plastic strain and ""p ?is the pre-strain at the initiation of reversal loading.Eq.(11)can be extracted by considering a super-position of two back-stress

vectors,

Fig.2.Tensile data curve ?tting by the Chaboche model and modi?ed model.

B.K.Chun et al./International Journal of Plasticity 18(2002)571–595577

? 1t 2e12TEach component of the back-stress is made to evolve independently so that di?erent kinematic shift can be realized for the initial and reversal loading:

:1?C 1

e à T"":p à 1"":p e13a T :2?C 2 e à T"":p for initial loading 0for reversal loading (e13b T

where C 1; ,and C 2are material (hardening)parameters to be determined.The Modi?ed Chaboche model is recovered when 2approaches zero (or C 2=0).An accompanying paper (Part II)by Chun et al.(2001)discusses a criterion to decide whether the current loading is a continuation of the initial loading or reversal load-ing.

Note that Eq.(13b)is linear,but can be generalized as in Chaboche model (Cha-boche and Rousselier,1981,1983;Lemaitre and Chaboche,1990).For example,the Armstrong–Frederick type of nonliear form can be assumed for the initial loading;

:2?C 2 e à T"":p à 2 2"":p for initial loading 0for reversal loading

(e13c T

In this case,an additional material parameter 2should be determined.It is deba-table whether this type of generalization is worth the e?ort or not.The simpler form,Eq.(13b),is suggested for springback prediction when a cyclic loading is expected during the forming process.There are only three hardening parameters (C 1; and C 2)to determine,in addition to the usual tensile data.

Under the uniaxial loading condition,for a monotonic tensile loading (0to "

"p ),a bound on the back-stress [Eq.(13b)]can be found as,

tension j j 4C 1

tC 2""p :e14a TFor a subsequent reversal loading from pre-strain "

"p ?to ""p , compression 4C 1

tC 2""p

?e14b T

Thus,

á ? tension j j à compression 4C 2e""p à""p ?Te14c T578 B.K.Chun et al./International Journal of Plasticity 18(2002)571–595

A possible o?set in?ow stress is modeled by considering the di?erence in the back-stress during the monotonic loading and reversal loading in this model as shown in above expressions.

The isotropic hardening part is governed by the same rule during the loading and reversal loading,through a curve?t to a tensile data,

tensile? otR ANKt e15aTwhere

?C1

e1àeà ""pTtC2""p with

C1

à 150e15bT

Substituting(15b)into(8a)with the use of(13b),the isotropic hardening part of ANK model can be written as,

R?R ANK?Ke1àeàN""pTàC1

e1àeà ""pTàC2""p with

C1

à 150e15cT

To compare the role of the kinematic hardening rule in the representation of a per-manent o?set,the Modi?ed Chaboche model is compared with the ANK model through a simple example.The two models share the same isotropic response,but di?er only in the kinematic hardening rule.

In this example,a cyclic in-plane plastic strain of+5andà15%is applied to one direction with the plane strain assumption in the second direction.The purpose of this exercise is to observe the evolution of the active yield surfaces for two models. Fig.3(a)and(b)show the comparison,for AL6022-T4and DQ steel,respectively. Numerical data are summarized in Table2.The ANK model clearly shows less kinematic shifts at the reversal loading for both materials,as expected.It is inter-esting to note that the?ow stresses computed by two models are slightly di?erent even though they use the same form for the isotropic response,because of the cou-pling e?ects.

4.Identi?cation ofthe mate r ial pa r amete r s

Identi?cation of material parameters associated with a selected plasticity model is a critical issue for the?nite element simulation of sheet metal forming processes. Several alternatives of the direct or indirect measurement for metal sheets have been proposed(Balakrishnan,1999;Shen,1999;Zhao,1999).Material parameters asso-ciated with the Modi?ed Chaboche model and ANK model can be identi?ed by curve?tting TC(or CT)test data or/and by using the inverse methods based on three-point bend tests(Zhao,1999;Zhao and Lee,1999,2000,2001a,b).

B.K.Chun et al./International Journal of Plasticity18(2002)571–595579

https://www.sodocs.net/doc/604106032.html,parison of active yield surfaces under tension and subsequent compression loading under the plane strain condition:(a)AL6022-T4;(b)DQ steel.

580 B.K.Chun et al./International Journal of Plasticity 18(2002)571–595

4.1.Material parameters from tension–compression curves

The T-C test of a sheet metal requires a delicate procedure to extract a stress–strain curve.However,once a?ow curve is obtained,the parameter identi?cation procedure is relatively simple.Geng(2000),Geng and Wagoner(2000)and Geng et al.(2001)presented the material parameters associated with the Geng–Wagoner model for three types of auto body alloys based on the in-plane test data by Balak-rishnan(1999).The material parameters associated with the Modi?ed Chaboche model(C,g,K,N)and ANK model(C1,C2,g,K,N)can be determined in the similar fashion.Two sets of parameters can be found by?tting to C-T data and T-C data for each material,as listed in Table3.Generated Bauschinger curves from the Modi?ed Chaboche model and ANK model are compared with the measured data in Figs.4and5for two alloys(AL6022-T4and DQ steel).The Modi?ed Chaboche model over estimates the reduced yield stress at reversal loading and is not capable of capturing the o?sets,as shown in Figs.4(a)and(b).The ANK model,in the mean time,seems to be able to reproduce the test data accurately including the permanent o?sets.

4.2.Material parameters from inverse method

The material parameters can be identi?ed also by applying one of the inverse methods proposed by Zhao(1999)and Zhao and Lee(1999;2000,2001a).The cur-rent work follows Zhao and Lee(2000)with modi?cations to?t the proposed hardening models.The basic idea is to employ the optimization technique based on micro genetic algorithm and the three-point bend(and reverse bend)test results (Zhao and Lee,1999).The three-point bend test measures;punch force,displace-ment,bend angle,surface strain.Measured quantities can be used to calculate‘‘exter-nal’’bending moment(M ext)due to punch load and to express‘‘internal’’bending moment(M int)in terms of measured strains and unknown material parameters.Then the di?erence between two moments(M intàM ext)can be optimized to determine the Table2

Comparison of the change in yield surfaces under tension and subsequent compression loading

Initial Tension Subsequent compression

o (MPa) x

(MPa)

y

(MPa)

o

(MPa)

x

(MPa)

y

(MPa)

o

(MPa)

x

(MPa)

y

(Mpa)

AL6022-T4

Modi?ed Chaboche17100205.949.117.2306.3à50.4à17.7 ANK229.524.08.4308.5à8.0à2.8 DQ steel

Modi?ed Chaboche17500228.842.724.1344.6à42.7à24.1 ANK228.443.324.4324.1à19.1à10.8

B.K.Chun et al./International Journal of Plasticity18(2002)571–595581

parameters associated with the speci?c model selected.The micro genetic algorithm is employed because it does not require the gradient of objective function.

A major question of this method is whether the material parameters determined by employing a relatively small maximum bending strain (2–5%,depending on the specimen thickness)can be e?ectively used when the expected forming strain is very high (as high as 10–20%).Pre-straining specimen prior to bend test may resolve the question perhaps.

The ANK model parameters (C 1,C 2,g )determined in this way are listed in Table 3and compared with T-C and C-T data ?t.Generated Bauschinger curves from the ANK model are compared with T-C and C-T test data in Fig.6(a)and (b)for two alloys.

5.Numerical implementation

Numerical implementation procedure of the Modi?ed Chaboche model and ANK model is outlined in this section.As usual,the additive decomposition of elastic and plastic strain rate is considered together with the normality condition,

":p ?l :@f @e à T

?l :a e16Twhere l :is the plastic strain-rate multiplier and the ?ow vector is de?ned by a ?P áe à Tin Eq.(1),or explicitly,

Table 3

Associated material parameters

Material Models C (Gpa)

R-values o (MPa)K (MPa)N E (Gpa)C 1

C 2 R0R45R90AL6022-T4

Modi?ed Chaboche

3.57

4.2ANK a

3.00.152000.730.440.631712159.568ANK b

5.00.29170ANK c

5.00.21150Tensile test

N/A N/A 0.730.440.63171N/A N/A 68DQ steel

Modi?ed Chaboche

10.6300ANK a

8.00.20310 1.291752459.1180ANK b

9.00.25280ANK c

10.0.31220Tensile test

N/A N/A 1.29175N/A N/A 180a

T-C test (Balakrishnan,1999)?tting result.b

C-T test (Balakrishnan,1999)?tting result.c Three-point bend test ?tting result.

582 B.K.Chun et al./International Journal of Plasticity 18(2002)571–595

https://www.sodocs.net/doc/604106032.html,parison of Bauschinger curves from the Modi?ed Chaboche model and ANK model with various pre-strains.Associated material parameters for two models are obtained from the T-C test data by Balakrishnan (1999):(a)AL6022-T4;(b)DQ steel.

B.K.Chun et al./International Journal of Plasticity 18(2002)571–595583

Fig.5.Bauschinger curves from the ANK model with various pre-strains.Associated material parameters are obtained from the C-T test data by Balakrishnan (1999):(a)AL6022-T4;(b)DQ steel.

584 B.K.Chun et al./International Journal of Plasticity 18(2002)571–595

https://www.sodocs.net/doc/604106032.html,parison of Bauschinger curves from the ANK model with the material parameters obtained by the inverse method (Zhao and Lee,2000)and three-point bend test:(a)AL6022-T4;(b)DQ steel.B.K.Chun et al./International Journal of Plasticity 18(2002)571–595585

a ?2e xx à xx Tà 12e yy à yy T??2? 22e yy à yy Tà 12e xx à xx T 2 66e xy à xy T

8<:9=;e17TThe true stress rate can be expressed as,

:?C e":àl :a Te18Twhere C is the elastic response matrix.The consistency condition can be stated as

f :?@f @e à T:e :à :Tt@f @ :o ?0e19T

where :o ?H "

":p and H ?H e"":p Tis the plastic modulus.From the consistency con-dition (19)with the kinematic evolution equation,Eq.(4)or (13),the plastic multi-plier can be expressed as,

l :?a T C "

:a T Ca tA iso tA kin

e20Twhere A iso ?2 o H "":p and A kin ?a T J .The vector J is de?ned as:

for the Modi?ed Chaboche model,

J ?2C 1e à Tà2 1 o for initial and reversal loading :e21a Tfor the ANK model with simple form [Eq.(13b)],

J ?2eC 1tC 2Te à Tà2 1 o for initial loading 2C 1e à Tà2 1 o for reversal loading

&e21b TFinally,the rate form can be written as,

:?C àCaa T C a T Ca tA iso tA kin ":?C ep ":e22T

The backward Euler method with R-residual algorithm (Cris?eld,1991)is used in this study to integrate the rate form of constitutive equation above.The R-residual scheme converts the integration of the rate form into the minimization of a stress residual https://www.sodocs.net/doc/604106032.html,petitive alternatives are discussed by Cris?eld (1991,1997)and Li (1996).The element sti?ness matrix is directly related to the tangent modulus C ep evaluated at each integration point,which governs the convergence rate of the glo-bal iterative scheme.Thus the consistent tangent modulus is essential to keep the

586 B.K.Chun et al./International Journal of Plasticity 18(2002)571–595

quadratic rate of convergence in the Newton–Raphson scheme (Simo and Taylor,1985,1986;Cris?eld,1987,1991).The tangent modulus can be derived by the con-sistent linearization of the update scheme.More detail of the associated ?nite element formulation with the Modi?ed Chaboche and ANK model is listed in the Appendix.

6.Model evaluation and numerical examples

Simple model cases (with one element)are tested to evaluate the e?ects of material models on the stress calculation under cyclic loading conditions.Three di?erent material models;Modi?ed Chaboche,ANK model,and Geng–Wagoner model are compared under a two-cycle test condition (pure bend and reverse bend)and a four-cycle test condition (in-plane loading).AL6022-T4data,listed in Table 3(a),are used for both cases.

The two-cycle pure bend test condition is shown in Fig.7,which is modeled with one shell element with 51integration points through the thickness to assure the numerical accuracy.C-T test data for AL6022-T4are used.Applied rotation at the free end is ?1.0radian,for the ?rst bending and reverse bending,respectively.Referring to Fig.8(a),all three models predicted almost identical stress distribution at the ?rst bending.The ANK model and Geng–Wagoner model produced almost identical stress distribution at the reverse bending as well,albeit di?erent back-stress distributions shown in Fig.8(b).Consequently,both models will result in very similar springback prediction under the two-cycle loading condition (bending and reverse bending),while the Modi?ed Chaboche model will not.

A hypothetical four-cycle test condition is analyzed next.The sample (10mm long and 1mm wide)is clamped at one end and subjected to a cyclic in-plane deforma-tion as shown in Fig.9.Fig.10(a)compares the stress–strain curves generated by the ANK model by employing three sets of material parameters for AL6022-T4listed in Table 3(a).The three models produce di?erent subsequent stress–strain curves after the initial tension,as expected.Although it is not clear whether AL6022-T4behaves di?erently under T-C condition from C-T condition,a pronounced di?erence in stress can be seen from Fig.10(a)between these two ?tting results.Curves generated from the three-point bend test and the inverse method seem to start from C-T test ?t and converge to T-C ?t,raising a question whether this method can be used to dis-criminate some erroneous in-plane test

data.

Fig.7.Bending and reverse bending process condition.

B.K.Chun et al./International Journal of Plasticity 18(2002)571–595587

The ANK model is compared with the Geng–Wagoner model in Fig.10(b)with C-T test data?t for AL6022-T4,which show almost identical results during the?rst two cycles,but remarkably di?erent at the third cycle(non-symmetrical reversal in

loading).The Geng–Wagoner model overshoots the stress during the third

cycle

https://www.sodocs.net/doc/604106032.html,parison of stress distributions through the thickness under bending and subsequent reverse bending:(a)axial stress;(b)back-stress.

588 B.K.Chun et al./International Journal of Plasticity18(2002)571–595

while the ANK model exhibits a consistent trend over the entire cycle.Similar overshooting was observed for a symmetrical reversal of the loading,but not shown in this paper.The Geng–Wagoner model might have been designed with only?rst two cycles of loading in mind.More comparisons and applications to?eld problems will be addressed in a companion paper(Part II).

7.Concluding remarks

An anisotropic nonlinear kinematic model(ANK model)is proposed together

with a simple modi?cation to the isotropic part of the Chaboche model to

better

Fig.9.Multi-cycle test condition with one element:(a)boundary condition;(b)loading condition for four-cycle test(T–C–T–C).

B.K.Chun et al./International Journal of Plasticity18(2002)571–595589

https://www.sodocs.net/doc/604106032.html,parison of four-cycle test results (AL6022-T4data from Balakrishnan,1999):(a)ANK model with three sets of parameters;(b)ANK model vs.Geng–Wagoner model with C-T test data.

590 B.K.Chun et al./International Journal of Plasticity 18(2002)571–595