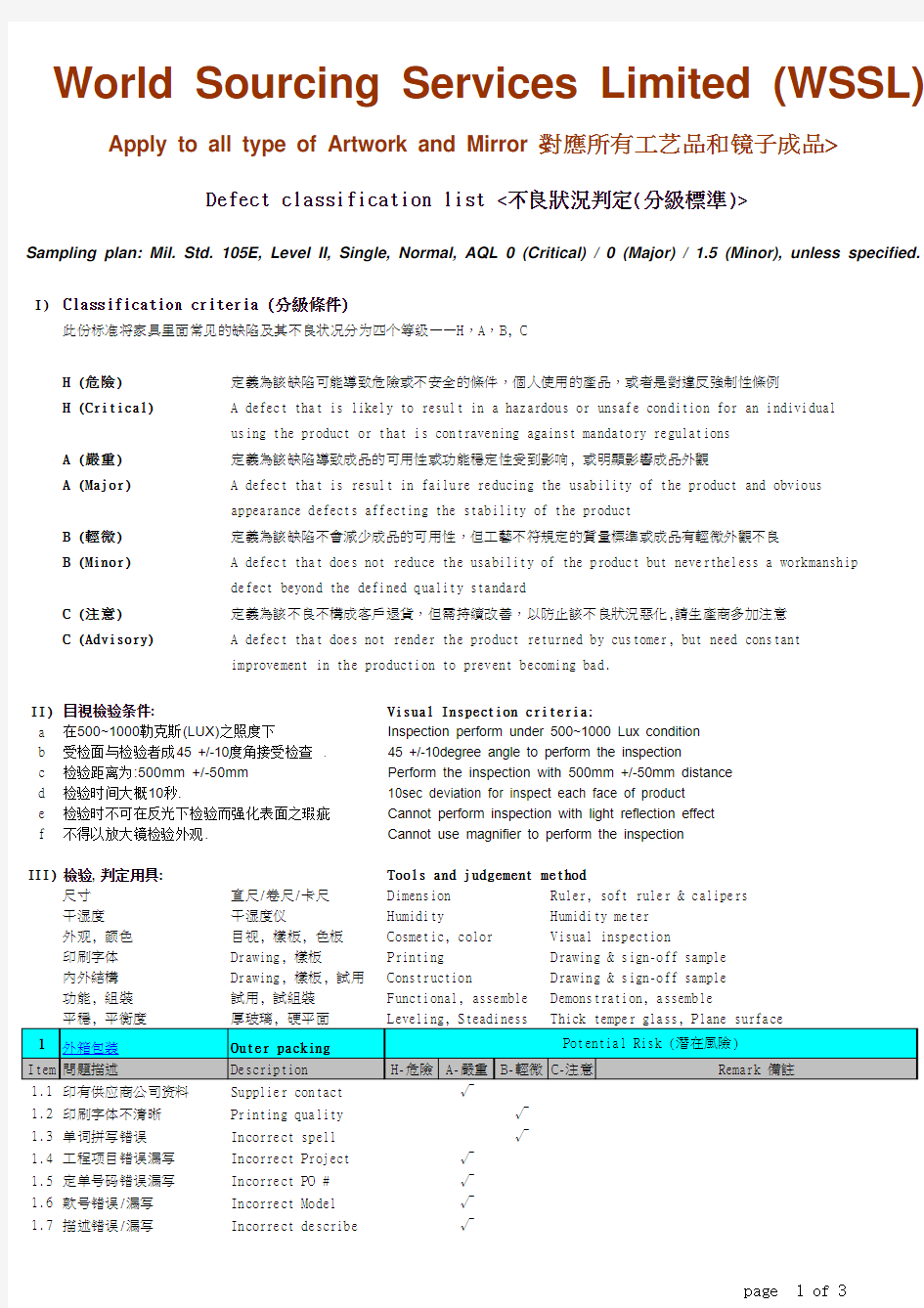

Artwork and mirror - defect classification list(1) (20090320))

I)

此份标准将家具里面常见的缺陷及其不良状况分为四个等级——H,A,B, C

H (危險)H (Critical)

A (嚴重) A (Major)

appearance defects affecting the stability of the product

B (輕微)B (Minor)

defect beyond the defined quality standard

C (注意)C (Advisory)

improvement in the production to prevent becoming bad.

II)目視檢验条件:

a 在500~1000勒克斯(LUX)之照度下

Inspection perform under 500~1000 Lux condition b 受检面与检验者成45 +/-10度角接受检查 .45 +/-10degree angle to perform the inspection

c 检验距离为:500mm +/-50mm Perform the inspection with 500mm +/-50mm distance

d 检验时间大概10秒.

10sec deviation for inspect each face of product e 检验时不可在反光下检验而强化表面之瑕疵Cannot perform inspection with light reflection effect f 不得以放大镜检验外观.III)檢验, 判定用具:

尺寸 直尺/卷尺/卡尺Dimension 干湿度 干湿度仪

Humidity 外观, 颜色 目视, 樣板, 色板Cosmetic, color 印刷字体 Drawing, 樣板

Printing 內外結構Drawing, 樣板, 試用Construction 功能, 組裝試用, 試組裝Functional, assemble

1.1印有供应商公司资料Supplier contact √

1.2印刷字体不清晰Printing quality √1.3单词拼写错误Incorrect spell √

1.4工程项目错误漏写Incorrect Project √1.5定单号码错误漏写Incorrect PO #√1.6款号错误/漏写Incorrect Model √1.7描述错误/漏写

Incorrect describe

√

Demonstration, assemble

World Sourcing Services Limited (WSSL)

Apply to all type of Artwork and Mirror <對應所有工艺品和镜子成品>

Classification criteria (分級條件)

定義為該缺陷可能導致危險或不安全的條件,個人使用的產品,或者是對違反強制性條例

Defect classification list <不良狀況判定(分級標準)>

Sampling plan: Mil. Std. 105E, Level II, Single, Normal, AQL 0 (Critical) / 0 (Major) / 1.5 (Minor), unless specified.

Visual Inspection criteria:

A defect that does not reduce the usability of the product but nevertheless a workmanship A defect that is result in failure reducing the usability of the product and obvious 定義為該不良不構成客戶退貨,但需持續改善,以防止該不良狀況惡化,請生產商多加注意Visual inspection Drawing & sign-off sample Cannot use magnifier to perform the inspection

定義為該缺陷不會減少成品的可用性,但工藝不符規定的質量標準或成品有輕微外觀不良

Humidity meter Drawing & sign-off sample A defect that is likely to result in a hazardous or unsafe condition for an individual using the product or that is contravening against mandatory regulations

定義為該缺陷導致成品的可用性或功能穩定性受到影响, 或明顯影響成品外觀

Ruler, soft ruler & calipers A defect that does not render the product returned by customer, but need constant Tools and judgement method

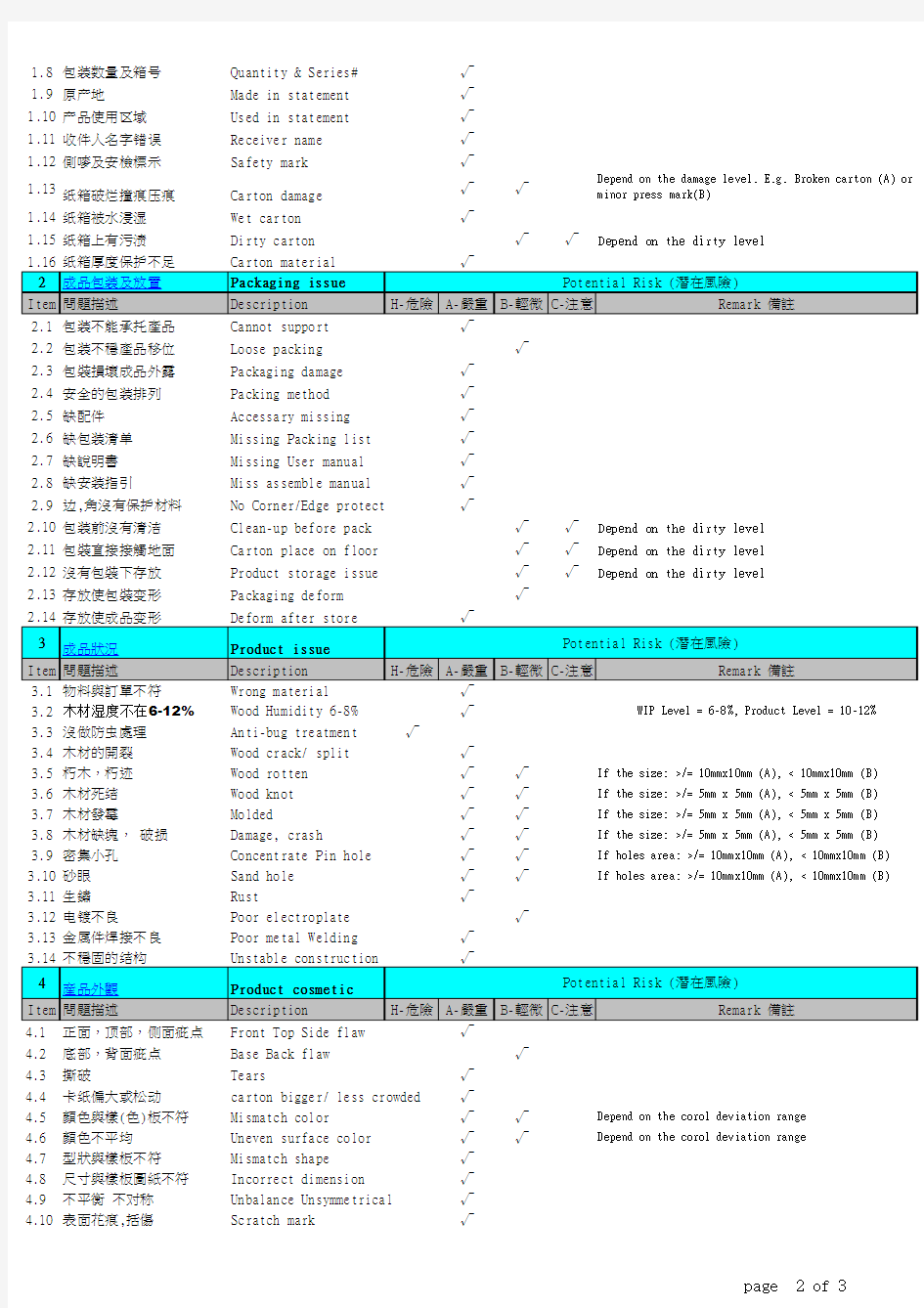

1.8包装数量及箱号Quantity & Series#√1.9原产地Made in statement √1.10产品使用区域Used in statement √1.11收件人名字错误Receiver name √1.12側嘜及安檢標示Safety mark √1.13纸箱破烂撞痕压痕Carton damage √√

Depend on the damage level. E.g. Broken carton (A) or minor press mark(B)

1.14纸箱被水浸湿Wet carton √

1.15纸箱上有污渍Dirty carton √

√

Depend on the dirty level

2.1包装不能承托產品Cannot support √

2.2包装不穩產品移位Loose packing √

2.3包裝損壞成品外露Packaging damage √2.4安全的包装排列Packing method √2.5缺配件Accessary missing √2.6缺包装清单Missing Packing list √2.7缺說明書Missing User manual √2.8缺安装指引Miss assemble manual √2.9边,角沒有保护材料No Corner/Edge protect √

2.10包装前沒有清洁Clean-up before pack √√Depend on the dirty level 2.11包裝直接接觸地面Carton place on floor √√Depend on the dirty level 2.12沒有包裝下存放Product storage issue √√

Depend on the dirty level

2.13存放使包裝变形Packaging deform √

3.1物料與訂單不符

Wrong material

√

3.2木材湿度不在6-12%Wood Humidity 6-8%

√

WIP Level = 6-8%, Product Level = 10-12%3.3沒做防虫處理Anti-bug treatment √3.4木材的開裂Wood crack/ split √3.5朽木,朽迹Wood rotten √√If the size: >/= 10mmx10mm (A), < 10mmx10mm (B)3.6木材死结Wood knot √√If the size: >/= 5mm x 5mm (A), < 5mm x 5mm (B)3.7木材發霉

Molded √√If the size: >/= 5mm x 5mm (A), < 5mm x 5mm (B)3.8木材缺塊, 破损Damage, crash √√If the size: >/= 5mm x 5mm (A), < 5mm x 5mm (B)3.9密集小孔Concentrate Pin hole √√If holes area: >/= 10mmx10mm (A), < 10mmx10mm (B)3.10砂眼Sand hole √√If holes area: >/= 10mmx10mm (A), < 10mmx10mm (B)3.11生鏽Rust √3.12电镀不良

Poor electroplate √3.13金属件焊接不良Poor metal Welding √4.1正面,顶部,侧面疵点Front Top Side flaw √

4.2底部,背面疵点Base Back flaw √

4.3撕破

Tears

√4.4卡纸偏大或松动

carton bigger/ less crowded √4.5顏色與樣(色)板不符Mismatch color

√√Depend on the corol deviation range 4.6顏色不平均

Uneven surface color √√

Depend on the corol deviation range

4.7型狀與樣板不符Mismatch shape

√4.8尺寸與樣板圖紙不符Incorrect dimension

√4.9不平衡 不对称Unbalance Unsymmetrical √4.10

表面花痕,括傷

Scratch mark

√

4.11切割痕跡Cutting mark√

4.12表面不平Flatness√

4.13表面有污穢Burnt/ dirt mark√√Depend on the dirty level

4.14表面有油污膠漬Glue/ grease mark√√Depend on the dirty level

4.15结合处有缝隙Joint slit√√Depend on the slit level

4.16凹痕,破洞Dent and crack√√

4.17釘,螺絲外露Nail screw exposure√

4.18返修痕跡Repair, mending mark√

4.19油漆龟裂,剥落Painting peel off√√Depend on the painting deviation range 4.20油漆厚薄不一致Uneven paint thickness√

4.21油漆有氣泡Bubble under paint√

4.22油漆有異物Dust under paint√

4.23上漆工藝不良Painting issue√

4.24貼箔不良Uneven laminate√√Depend on the uneven level

4.25表面脫落Surface peel off√

4.26彫刻花纹不对称Pattern not match√

4.27彫刻花纹不良Defect pattern √

4.28紋理不一致Texture not match√

4.29紋理方向不一致Direction not match√

4.30镜片厚度不足thickness insufficient√

4.31镜片有气泡Bubble on glass√

4.32镜片破裂Glass breakage√√Product could fall down (H)

4.33镜片有哈哈镜效果fun-house mirror effect√

Depend on the surface deviation range 5.2邊角手感不良Rough corner, edge√√Depend on the rough level

5.3內部手感粗糙Rough internal√√Depend on the rough level

5.4部件組裝不良Defect assemble√

5.5部件不能組裝Cannot assemble√√

5.6部件組裝錯誤Wrong assemble√

5.7部件接合後不穩Parts Wobble√

5.8裝配後部件变形Assemble deform√

5.9使用時產生不良Defect after use√

5.10使用時容易鬆脫Loose when use√√Product could fall down (H)

5.11不能正常使用Cannot function√

6.1部件规格與訂單不符Incorrect material√

6.2缺部件Missing part√

6.3缺螺絲或釘Missing screw or nail√

6.4部件变形Parts deform√

6.5部件脫落Parts peel off√√Product could fall down (H)

6.6部件鬆動Loose parts√

6.7裝飾品脱落Ornament peel off√√Ornament could fall down (H)

6.8裝飾品鬆脱Ornament loose√

6.9裝飾品外觀不良Defect Ornament√√Depend on the ornament deviation range