SAE J323-2004

SAE Technical Standards Board Rules provide that: “This report is published by SAE to advance the state of technical and engineering sciences. The use of this report is entirely voluntary, and its applicability and suitability for any particular use, including any patent infringement arising therefrom, is the sole responsibility of the user.”

SAE reviews each technical report at least every five years at which time it may be reaffirmed, revised, or cancelled. SAE invites your written comments and suggestions.Copyright ? 2004 SAE International

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted, in any form or by any means, electronic, mechanical, photocopying,recording, or otherwise, without the prior written permission of SAE.TO PLACE A DOCUMENT ORDER:

Tel: 877-606-7323 (inside USA and Canada)Tel: 724-776-4970 (outside USA)Fax: 724-776-0790

Email: custsvc@https://www.sodocs.net/doc/6411590382.html,

SURFACE VEHICLE

RECOMMENDED PRACTICE

An American National Standard

J323

REV.JAN2004

Issued 1968-08Revised

2004-01

Superseding J323 JUL1998

Test Method for Determining Cold Cracking of Flexible Plastic Materials

1.

Scope—This SAE Recommended Practice is applicable for determining the cold characteristics of flexible plastic materials, as applicable. It consists of three different methods for determining low-temperature properties of materials depending on type of material and end use.2.References

2.1

Applicable Publications—The following publications form a part of the specification to the extent specified herein.

2.1.1

ASTM P UBLICATION —Available from ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959.ASTM D 3574—Standard Test Methods for Flexible Cellular Materials—Slab, Bonded, and Molded

Urethane Foams

3.Method A, Mandrel Test 3.1Apparatus and Materials

3.1.1

M ANDREL —Steel mandrel nominally 6.35 mm in diameter and 152 mm long attached to a suitable stand.Other diameters may be specified depending on the thickness and rigidity of the material to be tested.3.1.2O VEN —Air-circulating oven capable of maintaining a temperature of 82 °C ± 2 °C.

3.1.3

C OL

D B OX —A cold box capable of maintaining a temperature of ?34 °C and large enough to permit bending the test specimen while it remains in the box.

3.1.4G LOVES —Heavy cloth gloves to prevent heat transfer when handling specimens.

3.2

Procedure—Cut 50 x 200 mm specimens in the machine and across machine direction and condition in the oven at 82 °C for 24 h or as specified. (The dimensions of the specimen may vary for extruded or molded parts.) Remove specimens from the oven and condition at room temperature until reaching equilibrium. Place specimens, gloves, and mandrel with stand in the cold box at ?34 °C for 4 h or as specified. Put on gloves and grasp each end of the sample and bend, around the mandrel in approximately 0.5 s with a uniform motion.Remove specimens from cold box and examine visually for evidence of cracks.

--`,,`,`,,``````,,``,,,,,,,,`,`-`-`,,`,,`,`,,`---

4.Method B, Impact Test

4.1Apparatus and Materials

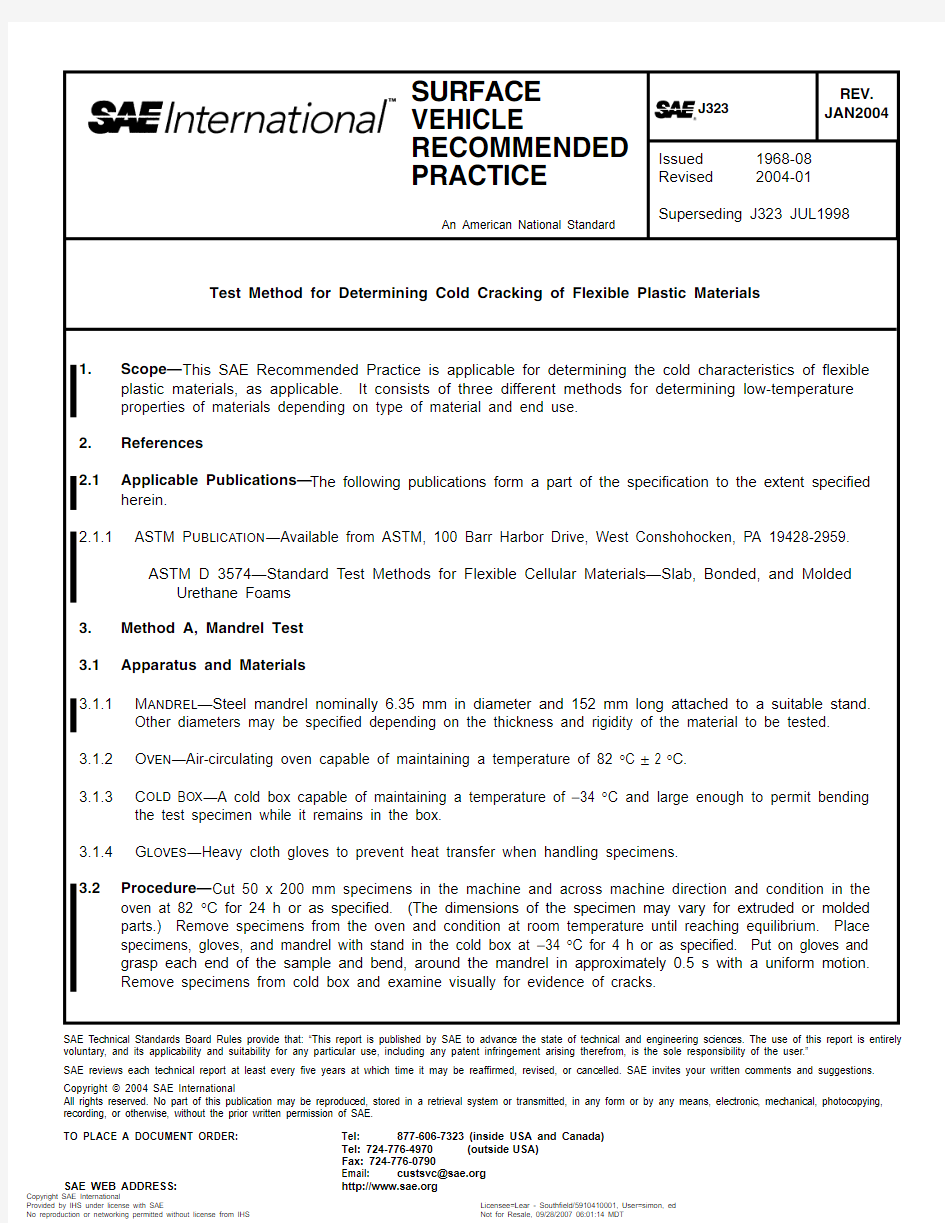

4.1.1I MPACT T ESTER—Impact tester capable of applying a 10.8 J impact with a spherical ball head having a radius

of 23.81 mm. (See Figure 1.)

NOTE—BOTH H AND W MAY BE VARIED AS L ONG AS HW = 10.8 J AND H IS NOT L ESS THAN

3.048mm. DIMENSION r OF PROJECTILE MUST BE 23.8 mm AND IS NOT VARIABLE.

FIGURE 1—IMPACT APPARATUS

4.1.2B ASE—A 102 x 102 x 19 mm thick wood base with an 89 x 89 mm square marked off in the center for stapling

specimen and a 76 x 76 mm square marked off for positioning urethane foam pad.1

4.1.3O VEN—Air-circulating oven capable of maintaining a temperature of 82 °C ± 2 °C.

1.Unless otherwise specified, the foam base shall be either a urethane or latex foam with the following load deflection characheristics.

The foam specimens shall be 100 x 100 mm by the thickness used or as appropriate to meet the load deflection requirements for pressure.

If using urethane the base material shall have the following load deflection characteristics when tested for CFD (Compression Force Deflection) per ASTM D 3574: the pressure on the specimen after compressing it 25% of its original thickness at room temperature and holding it there for one minute shall be 3.0 to 4.1 kPa. The foam shall also meet the following cold temperature requirement: After conditioning the specimen for 12 hours at -29° C immediately compress it with a pressure of 2.59 + 0.07 kPa and hold it for a minute. The compressed height of the specimen shall be 82 to 92% of the original specimen thickness.

If using latex the base material shall have the following load deflection characterstics when tested for CFD (Compression Force Deflection) per ASTM D 3574: the pressure on the specimen after compressing it 25% of its original thickness at room temperature

and holding it there for one minute shall be 2.5 to 3.1 kPa. The foam shall also meet the folllowing cold temperature requirement: After conditioning the speciment for 12 hours at ?29 °C immediately compress it with a pressure of 2.59 + 0.07 kPa and hold it for a minute. The compressed height of the specimen shall be 73 to 83% of the original specimen thickness.

NOTE—The wood and urethane foam base described previously was established primarily for vinyl-coated fabrics. Other flexible plastic materials may require modifications in the base depending on the flexibility of the material to be tested.--` , , ` , ` , , ` ` ` ` ` ` , , ` ` , , , , , , , , ` , ` -` -` , , ` , , ` , ` , , ` ---

4.2Procedure—Cut a 100 x 100 mm specimen of the flexible plastic material and age it in the oven at 82 °C for 7

days (or as specified by the contractual parties). Place a 75 x 75 x 19 mm thick urethane or latex foam pad in the center of the wood base and attach the aged specimen to the base by stapling 6 mm from the edge of the specimen as indicated in Figure 2 (staples should be 8 mm minimum length). Place the composite in the cold chamber at ?29 °C for a minimum of 12 h (or as specified by the contractual parties). While still at ?29 °C, the center of the test material shall be impacted with a force of 10.8J energy criteria or as otherwise agreed upon by the contractual parties. The height of the drop and the mass of the impactor shall be such that it meets the

10.8J energy criteria or as otherwise agreed upon by the contractual parties. Remove the composite from the

cold box and examine the flexible plastic material for cracks.

FIGURE 2—SPECIMEN AND SPECIMEN ON BASE

5.Method C, Dynamic Flex Test

5.1Apparatus

5.1.1C OLD B OX—A cold box capable of maintaining a temperature of ?29 °C and large enough to hold flexing

equipment.

5.1.2O VEN—Air-circulating oven capable of maintaining a temperature of 82 °C ± 2 °C.

5.1.3F LEXING E QUIPMENT—Dynamic flex equipment with reciprocating motion (see Figure 3).

5.2Procedure—Cut two or four specimens 75 x 50 mm, two specimens having the long dimension in the warp

direction and the remaining two having the long dimension in the filling direction, if applicable. Condition one or two specimens, if testing in both directions, for 7 days at 82 °C ± 2 °C in an air-circulating oven followed by 4 h at ?29 °C. Condition the remaining one or two specimen(s) at ?29 °C for 4 h. Clamp the two ends of the unaged specimen(s) in the cold flex apparatus with the finished side facing out. Flex at ?29 °C for 700 cycles at 90 cycles/min. Remove and examine for cracks. Flex the heat aged specimens for 600 cycles at the same rate. Remove and examine for cracks.--` , , ` , ` , , ` ` ` ` ` ` , , ` ` , , , , , , , , ` , ` -` -` , , ` , , ` , ` , , ` ---

FIGURE 3—BASIC DETAILS OF COLD FOLD TEST APPARATUS

6.Notes

6.1Marginal Indicia—The change bar (l) located in the left margin is for the convenience of the user in locating

areas where technical revisions have been made to the previous issue of the report. An (R) symbol to the left of the document title indicates a complete revision of the report.

PREPARED BY THE SAE TEXTILES AND FLEXIBLE PLASTICS COMMITTEE --` , , ` , ` , , ` ` ` ` ` ` , , ` ` , , , , , , , , ` , ` -` -` , , ` , , ` , ` , , ` ---

Rationale—The only changes to the document were in 3.1.1, the diameter and length were switched. Relationship of SAE Standard to ISO Standard—Not applicable.

Application—This SAE Recommended Practice is applicable for determining the cold characteristics of flexible plastic materials, as applicable. It consists of three different methods for determining low temperature properties of materials depending on type of material and end use.

Reference Section—There are no referenced publications specified herein.

Developed by the SAE Textiles and Flexible Plastics Committee

--`,,`,`,,``````,,``,,,,,,,,`,`-`-`,,`,,`,`,,`---