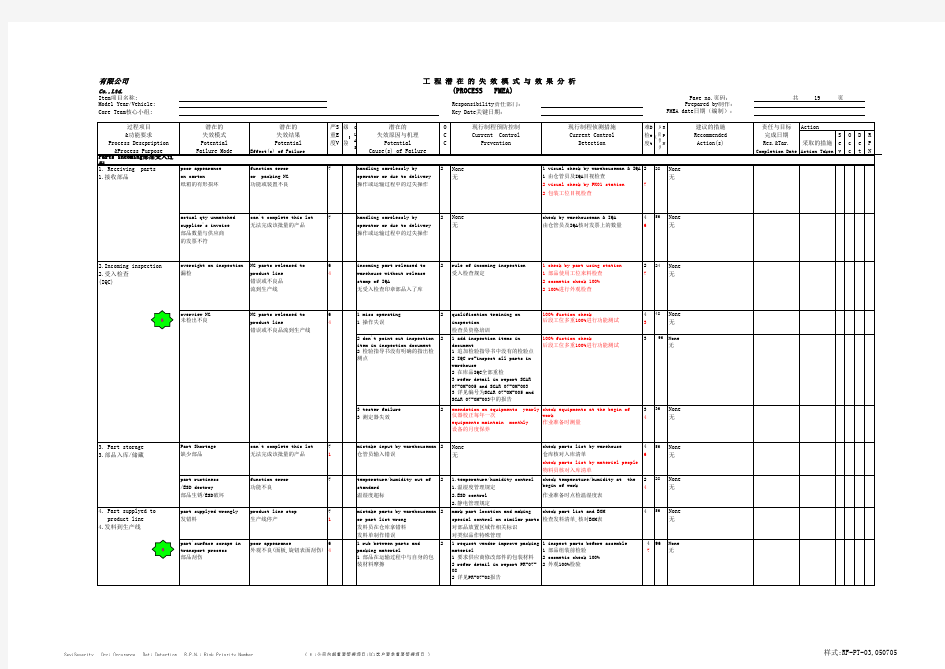

PFMEA 失效模式分析案例

Co.,Ltd.

(PROCESS FMEA)

Item项目名称:

Page no.页码:共19页

Model Year/Vehicle:Responsibility责任部门:Prepared by制作:

Core Team核心小组:

Key Date关键日期:

过程项目潜在的潜在的严S 级潜在的频O 现行制程预防控制现行制程侦测措施难D R 建议的措施责任与目标效果确认Action Results

&功能要求

失效模式失效结果重E

失效原因与机理度C Current Control

Current Control

检e P Recommended 完成日期S O D R

Process Descpription Potential Potential

度V 别Potential

数C Prevention Detection

度t

N Action(s)

Res.&Tar.

采取的措施e c e P

&Process Purpose

Failure Mode Effect(s) of Failure Cause(s) of Failure Completion Date Action Taken v c t N

Parts incoming部品受入过程1. Receiving parts poor appearance function error 7

handling carelessly by

2

None 1 visual check by warehouseman & IQA 2None 1.接收部品

on carton

or packing NG operator or due to delivery 无

1 由仓管员及IQA目视检查

无

纸箱的有形损坏

功能或装置不良

操作或运输过程中的过失操作

2 visual check by PK01 station 72 包装工位目视检查

actual qty unmatched with can't complete this lot 7

handling carelessly by

2

None check by warehouseman & IQA 4None supplier's invoice 无法完成该批量的产品operator or due to delivery 无由仓管员及IQA核对发票上的数量6

无

部品数量与供应商操作或运输过程中的过失操作

的发票不符

2.Incoming inspection oversight on inspection NG parts released to 6incoming part released to 2

rule of incoming inspection 1 check by part using station 2None 2.受入检查漏检

product line 4

warehouse without release 受入检查规定

1 部品使用工位来料检查7

无

(IQC)

错误或不良品stamp of IQA

2 cosmetic check 100%流到生产线

无受入检查印章部品入了库

2 100%进行外观检查

NG parts released to 6 1 miss operating 2

qualification training on 4None product line

4 1 操作失误

inspection

3无检查员资格培训

2 don't point out inspection item in inspection document 2 检验指导书没有明确的指出检测点

2

1 add inspection items in document

1 追加检验指导书中没有的检验点

2 IQC re-inspect all parts in warehouse

2 在库品IQC全部重检

3 refer detail in report SCAR 07-OM-005 and SCAR 07-OM-0033 详见编号为SCAR 07-OM-005 and SCAR 07-OM-003中的报告

100% fuction check

后段工位多重100%进行功能测试

3

None 无

3 tester failure 2

3None 3 测定器失效

4

无

3. Part storage Part Shortage can't complete this lot 7mistake input by warehouseman 2None check parts list by warehouse 4None 3.部品入库/储藏缺少部品无法完成该批量的产品1仓管员输入错误无

仓库核对入库清单

6

无

check parts list by materiel people 物料员核对入库清单

part rustiness function error 7

temperature/humidity out of 2

1.temperature/humidity control 2None /ESD destroy 功能不良

standard 1.温湿度管理规定4

无

部品生锈/ESD破坏

温湿度超标

2.ESD control 作业准备时点检温湿度表2.静电管理规定

4. Part supplyed to part supplyed wrongly product line stop 7mistake parts by warehouseman 2mark part location and making check part list and BOM 4None product line 发错料生产线停产1

or part list wrong special control on similar parts 检查发料清单,核对BOM表无

4.发料到生产线

发料员在仓库拿错料对部品放置区域作相关标识发料单制作错误

对类似品作特殊管理

part'surface scrape in transport process 部品刮伤

poor appearance 外观不良(面板,旋钮表面刮伤)64

1 rub between parts and packing materiel

1 部品在运输过程中与自身的包装材料摩擦

2 1 requset vender improve packing materiel 1 要求供应商修改部件的包装材料2 refer detail in report PR-07-08

2 详见PR-07-08报告

1 inspect parts before assemble 1 部品组装前检验

2 cosmetic check 100%2 外观100%检验47

None 无

100% fuction check

后段工位多重100%进行功能测试check temperature/humidity at the begin of work

overview NG 未检出不良

错误或不良品流到生产线

96

28

56

56

36

56

96

24

48

28

有限公司

工 程 潜 在 的 失 效 模 式 与 效 果 分 析

C

L

A

S

S 风险

优先率 FMEA date日期(编制):

emendation on equipments yearly 仪器校正每年一次equipments maintain monthly 设备的月度保养

check equipments at the begin of work 作业准备时测量6

6

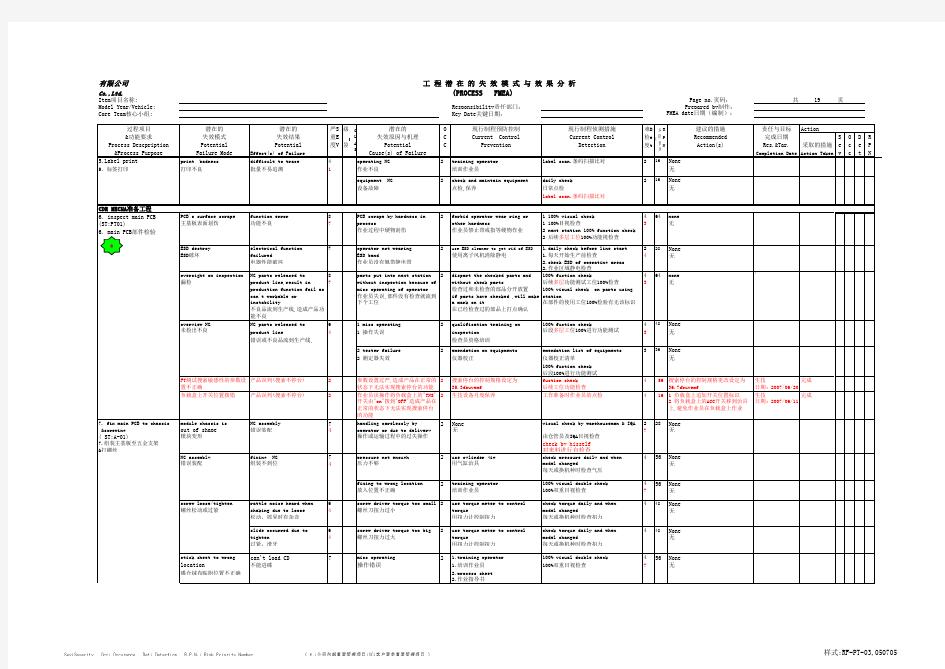

Co.,Ltd.

(PROCESS FMEA)

Item项目名称:

Page no.页码:共19页

Model Year/Vehicle:Responsibility责任部门:Prepared by制作:

Core Team核心小组:Key Date关键日期:

过程项目潜在的潜在的严S 级潜在的频O 现行制程预防控制现行制程侦测措施难D R 建议的措施责任与目标效果确认Action Results

&功能要求

失效模式失效结果重E

失效原因与机理度C Current Control

Current Control

检e P Recommended 完成日期S O D R

Process Descpription Potential Potential

度V 别Potential

数C Prevention

Detection

度t N Action(s)

Res.&Tar.

采取的措施e c e P

&Process Purpose Failure Mode Effect(s) of Failure Cause(s) of Failure Completion Date Action Taken v c t N

有限公司

工 程 潜 在 的 失 效 模 式 与 效 果 分 析

C

L

A

S

S 风险

优先率 FMEA date日期(编制):

https://www.sodocs.net/doc/a05366585.html,bel print print badness difficult to trace 4operating NG 2training operator label scan.条码扫描比对2None 5.标签打印

打印不良

批量不易追溯

1

作业不良培训作业员

无equipment NG 2

check and maintain equipment daily check 2

None 设备故障

点检,保养

日常点检

无

label scan.条码扫描比对

CDR MECHA准备工程PCB's surface scrape 主基板表面划伤function error 功能不良87

PCB scrape by hardness in process

作业过程中硬物刮伤2

forbid operator wear ring or other hardness

作业员禁止带戒指等硬物作业

1 100% visual check 1 100%目视检查

2 next station 100% function check 2 后续多层工位100%功能视检查

43

none 无

ESD destroy electrical function 7operator not wearing 2

use ESD cleaner to get rid of ESD

1.daily check before line start 2None ESD破坏

failured ESD band

使用离子风机消除静电 1.每天开始生产前检查

4

无电器性能破坏

作业员没有佩带静电带

2.check ESD of operating areas 2.作业区域静电检查

oversight on inspection 漏检NG parts released to product line,result in

production function fail as can't workable or instability

不良品流到生产线,造成产品功能不良

87

parts put into next station without inspection because of miss operating of operator 作业员失误,部件没有检查就流到下个工位

2dispart the checked parts and without check parts 检查过和未检查的部品分开放置if parts have checked ,will make a mark on it 在已经检查过的部品上打点确认100% fuction check 后续多层功能测试工位100%检查100% visual check on parts using station 在部件的使用工位100%检验有无该标识43

none 无

`

NG parts released to 6 1 miss operating 2

qualification training on 4None product line

4 1 操作失误inspection

3无检查员资格培训

2 tester failure 2

emendation on equipments emendation list of equipments 3

None 2 测定器失效

仪器校正

仪器校正清单

无

100% fuction check 后段100%进行功能测试FT测试搜索敏感性的参数设置不正确

产品误判(搜索不停台)2参数设置过严,造成产品在正常的状态下无法实现搜索停台的功能2搜索停台的控制规格设定为35.3dbuvemf

fuction check 后续工位功能检查

4搜索停台的控制规格更改设定为

36.7dbuvemf

生技日期: 2007/06/20完成负载盒上开关位置拨错产品误判(搜索不停台)

2

作业员误操作将负载盒上的"TNS"开关由"on"拨到"OFF"造成产品在正常的状态下无法实现搜索停台的功能

2生技设备月度保养

工作准备时作业员的点检

4

1 负载盒上追加开关位置标识

2 将负载盒上的ACC开关移到治具上,避免作业员在负载盒上作业生技日期: 2007/06/11

完成7. fix main PCB to chassis

module chassis is

NG assembly 7handling carelessly by 2None 2None &screwing

out of shape 错误装配4

operator or due to delivery 无

7无

( ST:A-01)

模块变形

操作或运输过程中的过失操作

由仓管员及IQA目视检查

7.组装主基板至五金支架check by hisself &打螺丝

对来料进行自检查

NG assembly fixing NG 7pressure not enough 2

use cylinder jig check pressure daily and when 4None 错误装配

组装不到位

4压力不够

用气缸治具

model changed

无每天或换机种时检查气压fixing to wrong location 2

training operator 100% visual double check 4None 放入位置不正确

培训作业员

100%双重目视检查

7无screw loose/tighten rattle noise heard when 6screw driver torque too small 2use torque meter to control check torque daily and when 4

None 螺丝松动或过紧

shaking due to loose 4

螺丝刀扭力过小

torque

model changed

无松动,摇晃时有杂音用扭力计控制扭力

每天或换机种时检查扭力slide occurred due to 6screw driver torque too big 2use torque meter to control check torque daily and when 4None tighten 4螺丝刀扭力过大

torque

model changed

无过紧,滑牙

用扭力计控制扭力每天或换机种时检查扭力stick sheet to wrong

can't load CD 7miss operating 2

1.training operator 100% visual double check 4None location

不能进碟

操作错误

1.培训作业员100%双重目视检查

7

无

碟仓绒布贴附位置不正确

2.process sheet 2.作业指导书

100% fuction check

后段多层工位100%进行功能测试

visual check by warehouseman & IQA 16

16

28

64

56

56

64

56

28

36

165648

48

错误或不良品流到生产线,

48

6. inspect main PCB (ST:PT01)

6. main PCB部件检验

overview NG 未检出不良

6

Co.,Ltd.

(PROCESS FMEA)

Item项目名称:

Page no.页码:共19页

Model Year/Vehicle:Responsibility责任部门:Prepared by制作:

Core Team核心小组:

Key Date关键日期:

过程项目潜在的潜在的严S 级潜在的频O 现行制程预防控制现行制程侦测措施难D R 建议的措施责任与目标效果确认Action Results

&功能要求

失效模式失效结果重E

失效原因与机理度C Current Control

Current Control

检e P Recommended 完成日期S O D R

Process Descpription Potential Potential

度V 别Potential

数C Prevention

Detection

度t N Action(s)

Res.&Tar.

采取的措施e c e P

&Process Purpose

Failure Mode Effect(s) of Failure Cause(s) of Failure Completion Date Action Taken v c t N

有限公司

工 程 潜 在 的 失 效 模 式 与 效 果 分 析

C

L

A

S

S

风险

优先率

FMEA date日期(编制):

PCB crack/scratch function error

7miss operating

2

1.training operator 100% visual check

4None PCB 断裂/ 划伤

功能不良操作失误

1.培训作业员

100%目视检查

3

无

2.jig for avoiding missing 2.防呆治具

incoming part NG 2

PCB cosmetic check

incoming inspection 2None 来料不良

PCB板外观检查

受入检查

3

无

100% check fuction repeatedly 后段多层工位100%进行功能测试

forget to stick heat NG assembly 7miss operating 2

1.manage by quantity 100% visual check by hisself 4None sink sheet to PCB 错误装配4

操作错误

1 数量管理

100%目视自检8

无

漏贴散热胶布至PCB

2.process sheet 2.作业指导书

ESD destroy electrical function 7

operator not wearing 2

use ESD cleaner to get rid of ESD

1.daily check before line start 2None ESD破坏

failured ESD band

使用离子风机消除静电

1.每天开始生产前检查

4

无电器性能破坏作业员没有佩带静电带 2.check ESD of operating areas 2.作业区域静电检查

space between panel fixing NG

3block of fixing jig shifted 2 1.check this item when monthly

1 visual check by hisself after

3None bottom and chassis 组装不到位面板底盖定位块的位置发生偏移

maintenance assemble

7

无

is too big when 1.治工具月度维护时重点检查此项目 1 组装后自检

assembly

2 next station check 组装时面板底盖与五金支架 2 后工位检查

之间间隙过大screw of jig loosed NG assembly 3

the screw is used to fix the 2 1.check this item when monthly 1 visual check by hisself after 3None 治具螺丝松动

错误装配

pillar of cylinder and pillar maintenance assemble

7

无

of press,it's easy to become 1.治工具月度维护时重点检查此项目 1 组装后自检

loose when using

2 next station check 该螺丝用于连接汽缸杆与受力杆, 2 后工位检查

使用中易松动

post beside sheet leather NG assembly 3

this item is not treated as 2None 1.IQC added this item to inspection 4None plate of bottom panel 错误装配important item when inspection 无process sheet

无

is anamorphic

IQC检查时未将此项列入重点检查 1.IQC将此项列入受入检查的重点检查项目面板底盖贴附碟仓绒布处项目

2.100% visual inspection 支柱变形

2.100%目视检查

螺丝刀碰伤主基板回路功能不良(AM无反应)7

治具上有多余的孔,作业员锁螺丝时打错位置,将主基板上的回路钻断

2治具上的螺丝孔位有标识

100% function check 100% 功能检查

4治具改造,将治具上多余的孔位去

除

生技日期:

2007/08/07

完成

100% check fuction repeatedly 后段多层工位100%进行功能测试56

18

18

24

5628

28

56

3

Co.,Ltd.

(PROCESS FMEA)

Item项目名称:

Page no.页码:共19页

Model Year/Vehicle:Responsibility责任部门:Prepared by制作:

Core Team核心小组:Key Date关键日期:

过程项目潜在的潜在的严S 级潜在的频O 现行制程预防控制现行制程侦测措施难D R 建议的措施责任与目标效果确认Action Results

&功能要求

失效模式失效结果重E

失效原因与机理度C Current Control

Current Control

检e P Recommended 完成日期S O D R

Process Descpription Potential Potential 度V 别Potential

数C Prevention

Detection

度t

N Action(s)

Res.&Tar.

采取的措施e c e P

&Process Purpose Failure Mode Effect(s) of Failure Cause(s) of Failure Completion Date Action Taken v c t N

有限公司

工 程 潜 在 的 失 效 模 式 与 效 果 分 析

C

L

A

S

S

风险

优先率

FMEA date日期(编制):

1 shock top cover by operator's mistake and make distortion of CD module

1 作业动作过失磨擦上盖导致机芯变形

4

can not superpose CD module in check process 检测过程中不能叠放

1 100% function check

2 100% visual check 1 100% 功能检查2 100% 目视检查

23

None 无

2 Test CD dirty 2 碟片赃污

4

check and maintain Test CD before operation

作业员作业前先进行光盘点检function check 功能检查23

None 无

CD module'axes lock CD 机芯前轴卡住CD碟function errer(CD is not workable and feedback)功能不良(无法读碟)87

shock parts and make distortion of CD module 部品碰撞变形

4

check appearance 检查确认外观

100% function check 功能检查

23None 无oversight on inspection 漏检

NG parts released to product line,result in production function fail as can't workable or instability

不良品流到生产线,87parts put into next station without inspection because of miss operating of operator 作业员失误,部件没有检查就流到下个工位2dispart the checked parts and without check parts

检查过和未检查的部品分开放置if parts have checked ,will make a mark on it

在已经检查过的部品上打点确认100% fuction check

后续功能测试工位100%检查

100% visual check on parts using station

在部件的使用工位100%检验有无该标识3

none 无

NG parts released to 6 1 miss operating 2

qualification training on 4None product line

4

1 作业员失误,

inspection

3

无

错误或不良品流到生产线,

检查员资格培训

2

2 tester failure 2

3None 2 测定器失效

4

无

not fix FFC steady function error

8

miss operating 2

1.make jig to insert FFC 3None 功能不良(FR,RR声道无输出)7

作业员过失

1.制做FFC排线插入治具

6

无

insert FFC flatly function error 7miss operating 2

1.training operator 100% visual check

4None FFC未水平插入

功能不良作业员过失

1.培训作业员100%目视检查并打点确认6

无

2.process sheet 2.作业指导书

治具排线端子与机芯接触不良

产品误判(按出碟键无反应)7

治具上的FFC排线多次使用后磨损,造成与机芯接触不良2

将FFC排线列为易损件,每月进行

更换

fuction check 后续工位功能检查3治具改造,在治具上追加FFC排线快速夹子生技日期: 2007/06/18

完成1.training operator 9.insert FFC&SCD module spring of mecha fall off function error 7miss operating 2

1.培训作业员

100% visual inspection 4None preparation&bracket screwing 机芯弹簧脱落功能不良

操作错误

100%目视检查3

无

(ST: A-02)

fuction check

9.FFC排线插入&机芯准备&后续工位功能检查 机芯支架打螺丝

incoming part NG 2

None incoming inspection 2

None 来料不良

无

受入检查

无

100% fuction check 后续工位功能检查

ESD destroy electrical function 8Operator not wearing 2use ESD cleaner to get rid of ESD

2None ESD破坏

failured 7

ESD band

使用离子风机消除静电

4

无

电器性能破坏

作业员没有佩带静电带

作业前检查静电

screw loose/tighten rattle noise heard when 6screw driver torque too small 2use torque meter to control check torque daily and when 4None 螺丝松动/过紧shaking due to loose 4螺丝刀扭力过小torque

model changed

无

松动,摇晃时有杂音

用扭力计控制扭力

每天或换机种时检查扭力

2.add correct method to carry CD module process sheet

2.作业指导书追加机芯的正确握取方法

2.add the correct method of insertting FFC into process sheet

2.在作业指导书内追加FFC排线的正确插入方法

1.100% visual inspection after FFC was inserted, and add mark on FFC cable,

1.FFC插入后100%目视检查,检查ok后在FFC排线上打点做标识,

2 check mark 100% next station 2 后工位在100%目测检查标识

56

100% fuction check

后续功能测试工位100%检查

check ESD of operating areas befor line start

64

64

64

48

56

64

test CD can not insert into SCD module CD机芯不入碟

function errer 功能不良87

48

28

FFC未固定(没有扣上 固定FFC排线的固定扣)

8. inspect SCD module (ST:PT-02)

8. CD机芯部件的检查

overview NG 未检出不良

32

56

36

emendation on equipments yearly 仪器校正每年一次equipments maintain monthly 设备的月度保养

check equipments at the begin of work始业点检6

4

Co.,Ltd.

(PROCESS FMEA)

Item项目名称:

Page no.页码:共19页

Model Year/Vehicle:Responsibility责任部门:Prepared by制作:

Core Team核心小组:

Key Date关键日期:

过程项目潜在的潜在的严S 级潜在的频O 现行制程预防控制现行制程侦测措施难D R 建议的措施责任与目标效果确认Action Results

&功能要求

失效模式失效结果重E

失效原因与机理度C Current Control

Current Control

检e P Recommended 完成日期S O D R

Process Descpription Potential Potential

度V 别Potential

数C Prevention

Detection

度t N Action(s)

Res.&Tar.

采取的措施e c e P

&Process Purpose

Failure Mode

Effect(s) of Failure Cause(s) of Failure Completion Date Action Taken v c t N

有限公司

工 程 潜 在 的 失 效 模 式 与 效 果 分 析

C

L

A

S

S

风险

优先率

FMEA date日期(编制):

slide occurred due to 6screw driver torque too big 2

use torque meter to control check torque daily and when 4

None tighten 4

螺丝刀扭力过大

torque

model changed

无

过紧,滑牙

用扭力计控制扭力

每天或换机种时检查扭力

can not fix screw to fixing NG 7torque is to small(5±2kgf)3

increase torque to 6.75±1.25 1.check torque daily and when 2None bracket

组装不到位4螺丝刀设定力矩规格过小

kgf base on technical spc and model changed

3

无

机芯防尘支架螺丝打不进

test result,and revised CP and 1.每天或换机种时检查扭力

process sheet

2.operator confirms screwing well 根据设计规格和实际打螺丝测试结after fixing

结果,将力矩调至.75±1.25 kgf,并 2.作业员组装完毕后100%目视检查螺丝修订控制计划和作业指导书

打入良好

10. bracket-m screwing &fix

螺丝松动/过紧

shaking due to loose 6螺丝刀扭力过小

torque

model changed

4

None shield case&fix FFC holder&

松动,摇晃时有杂音4用扭力计控制扭力

每天或换机种时检查扭力无stick cushion dustproof

(ST: A-03)

slide occurred due to 6screw driver torque too big 2

use torque meter to control check torque daily and when 4

None 10.机芯支架打螺丝&防护盖组装&tighten 4

螺丝刀扭力过大

torque

model changed

无

FFC支架组装&防尘胶布贴附

过紧,滑牙

用扭力计控制扭力

每天或换机种时检查扭力

ESD destroy electrical function 8operator not wearing 2

use ESD cleaner to get rid of ESD

1.daily check before line start 2None ESD破坏

failured 7

ESD band

使用离子风机消除静电

1.每天开始生产前检查

4

无

电器性能破坏

作业员没有佩带静电带 2.check ESD of operating areas 2.作业环境静电检查

forget to fix FFC holder NG assembly

7miss operating

2

1.training operator 100% visual double check 4None FFC支架漏装错误装配

4

操作错误

1.培训作业员100%双重目视检查

7

无

2.process sheet 2.作业指导书

forget to stick cushion NG assembly 7miss operating 2

1.training operator 100% visual check 4None dustproof to bracket 错误装配4

操作错误

1.培训作业员100%目视检查8

无

漏贴防尘胶布至机芯支架

2.process sheet 2.作业指导书

not combine two of NG assembly 7miss operating

2

1.training operator 100% visual check 4None dustproof completely 错误装配4操作错误,操作后未做压紧动作 1.培训作业员

100%目视检查8

无

防尘胶布接合处不紧密

2.process sheet update

2.修改作业指导书(追加NG和OK品

FFC fixing NG function error 7

miss operating

2

None 4None 排线组装不到位

功能不良

操作错误

无

2

无

not fix FFC steady function error 7miss operating 2

1.training operator 4None FFC未固定

功能不良操作错误

1.培训作业员6

无

2.process sheet 2.作业指导书check by fixture 用治具检查FFC holder

NG fixing 7miss operating 2 1.培训作业员100%目视检查

4None 排线未放入排线支架错误装配4

操作错误

2.process sheet 8

无

2.作业指导书3 using fixture 3 应用治具进行固定

sheet which is used to function error

8miss operating 2

training operator 100% visual inspection 4none connect FFC and main PCB 功能不良(机芯不动作)7

操作错误,操作后未做压紧动作

培训作业员

100%目视检查8

无

is not sticked firmly add this item as notice point FFC与基板连接胶布未贴紧

into process sheet

将此项目作为作业注意点追加至作业指导书

100% double visual check and make a mark on ok product

双重目视检查和打点确认check by fixture 用治具检查

100% double visual check and make a mark on ok product

双重目视检查和打点确认

42

56

48

56

48

32

56

64

56

56

56

2

5

5

Co.,Ltd.

(PROCESS FMEA)

Item项目名称:

Page no.页码:共19页

Model Year/Vehicle:Responsibility责任部门:Prepared by制作:

Core Team核心小组:

Key Date关键日期:

过程项目潜在的潜在的

严S 级潜在的频O 现行制程预防控制现行制程侦测措施难D R 建议的措施责任与目标效果确认Action Results

&功能要求

失效模式失效结果重E

失效原因与机理度C Current Control

Current Control

检e P Recommended 完成日期S O D R

Process Descpription Potential Potential

度V 别Potential

数C Prevention

Detection

度t N Action(s)

Res.&Tar.

采取的措施e c e P

&Process Purpose

Failure Mode Effect(s) of Failure Cause(s) of Failure Completion Date Action Taken v c t N

有限公司

工 程 潜 在 的 失 效 模 式 与 效 果 分 析

C

L

A

S

S 风险

优先率 FMEA date日期(编制):

11. fix assy module to chassis

ESD destroy electrical function 8operator not wearing 2

use ESD cleaner to get rid of ESD

1.daily check before line start 2None

&heat sink preparation ESD破坏

failured 7

ESD band

使用离子风机消除静电 1.每天开始生产前检查

4

无

11.机芯模块组装至底盖&电器性能破坏

作业员没有佩带静电带

2.operation condition ESD check 散热板准备 2.作业环境静电检查

(ST:A-04)

screw loose/tighten rattle noise heard when 6screw driver torque too small 2use torque meter to control check torque daily and when 4None 螺丝松动/过紧shaking due to loose 4螺丝刀扭力过小

torque

model changed

无

松动,摇晃时有杂音用扭力计控制扭力

每天或换机种时检查扭力slide occurred due to 6screw driver torque too big 2use torque meter to control check torque daily and when 4None tighten 4螺丝刀扭力过大

torque

model changed

无过紧,滑牙

用扭力计控制扭力

每天或换机种时检查扭力12.panel rear & heat sink screw loose/tighten rattle noise heard when 6screw driver torque too small 2use torque meter to control check torque daily and when 4None screwing

螺丝松动/过紧

shaking due to loose 4

螺丝刀扭力过小

torque

model changed

无

12.后盖&散热板打螺丝

松动,摇晃时有杂音

用扭力计控制扭力

每天或换机种时检查扭力

(ST:A-05)

slide occurred due to 6screw driver torque too big 2

use torque meter to control check torque daily and when 4None tighten 4螺丝刀扭力过大

torque

model changed

无过紧,滑牙

用扭力计控制扭力

每天或换机种时检查扭力

skid of screw 螺丝打滑

rattle noise heard when shaking due to loose 机台摇晃时有杂音,螺丝不紧易掉落

64 1 oprator isn't upright to lock screw

1 作业员没有垂直打螺丝

2 strength of screw is 8.0+-1kgf.cm which is excess

2 螺丝刀扭力8.0+-1kgf.cm规格过大

2

1 use torque meter to control torque

1 用扭力计控制扭力

2 defind the method of using screwdriver

2 电动螺丝刀使用方法定义

3 defind the strength of screw detail as 5±1kgf.cm 3 重新定义螺丝扭力为:5±1kgf.cm

1 voice/cosmetic station 100% check 1 外观工位100%异音/目视检查

47

None 无

48

48

48

48

3248

5

6

Co.,Ltd.

(PROCESS FMEA)

Item项目名称:

Page no.页码:共19页

Model Year/Vehicle:Responsibility责任部门:Prepared by制作:

Core Team核心小组:

Key Date关键日期:

过程项目潜在的潜在的严S 级潜在的频O 现行制程预防控制现行制程侦测措施难D R 建议的措施责任与目标效果确认Action Results

&功能要求

失效模式失效结果重E

失效原因与机理度C Current Control

Current Control

检e P Recommended 完成日期S O D R

Process Descpription Potential Potential

度V 别Potential

数C Prevention

Detection

度t N Action(s)

Res.&Tar.

采取的措施e c e P

&Process Purpose Failure Mode Effect(s) of Failure Cause(s) of Failure

Completion Date Action Taken v c t N

有限公司

工 程 潜 在 的 失 效 模 式 与 效 果 分 析

C

L

A

S

S 风险

优先率

FMEA date日期(编制):

13.panel top screwing and screw loose/tighten rattle noise heard when 6screw driver torque too small 2use torque meter to control check torque daily and when 4

None labeling&Visual Inspection 螺丝松动/过紧

shaking due to loose 4螺丝刀扭力过小

torque

model changed

无

13.上盖打螺丝&贴标签&外观检查

松动,摇晃时有杂音

用扭力计控制扭力

每天或换机种时检查扭力

(ST:A-06)

slide occurred due to 6screw driver torque too big 2

use torque meter to control check torque daily and when 4None tighten 4螺丝刀扭力过大

torque

model changed

无

过紧,滑牙

用扭力计控制扭力每天或换机种时检查扭力assembly NG NG fixing 7miss operating 2operate by fixture 100% visual check 4None 组装不到位

错误装配

4

操作错误

用治具按压

100%目视检查8无pressure not enough 2

use cylinder jig 100% visual check 4None 压力不够

用气缸治具100%目视检查

8无forget to stick label poor appearance 6operator carelessness 2training operator 100% double visual check 4None 标签漏贴

外观不良4操作员过失培训作业员100%双重目视检查

7无rear screw of cd-ch loose

parts fall off 7

incoming parts NG 2none 100% double visual check 2None 机芯尾部螺丝松动部品脱落

来料不良

无100%多重目视检查

7无screw high-up poor appearance 6operator oversight 2none 100% double visual check 4None 螺丝未完全打入

外观不良

4作业员漏检无100%多重目视检查

5无FA02工位100%进行螺丝紧固确认14. SPRING CLEAN less than clean time corrode plastic knob 6

operating NG 2none use timer to control clear time 2

None 14.弹簧片清洗

(2 minutes)

腐蚀塑胶旋钮

作业不良

无

用计时器控制清洗时间

无

(ST-S1)

少于清洗规定时间(2分钟)PCB's surface scrape PCB表面划伤function error 基板功能不良7

PCB scrape by hardness in process

作业过程中硬物刮伤2

forbid operator wear ring or other hardness

作业员禁止带戒指等硬物作业

function double check 后续工位功能检查

3ESD destroy electrical function 7

operator not wearing 2

use ESD cleaner to get rid of ESD

1.daily check before line start 2None ESD破坏

failured ESD band

使用离子风机消除静电 1.每天开始生产前检查

无电器性能破坏

作业员没有佩带静电带

2.check ESD of operating areas 2.作业区域静电检查

oversight on inspection 漏检

NG parts released to product line,result in

production function fail as can't workable or instability

不良品流到生产线,造成产品功能不良

8

4

parts put into next station without inspection because of miss operating of operator 作业员失误,部件没有检查就流到下个工位

2dispart the checked parts and without check parts 检查过和未检查的部品分开放置if parts have checked ,will make a mark on it 在已经检查过的部品上打点确认100% fuction check 后续功能测试工位100%检查100% visual check on parts using station 在部件的使用工位100%检验有无该标识43

none 无

NG parts released to 6 1 miss operating 2

qualification training on 4None product line 4 1 操作失误

inspection

3

无

错误或不良品流到生产线,

检查员资格培训

2 tester failure 2

3None 2 测定器失效

4无

开关基板按键损坏

功能不良(FM按键无反应)

7

进行按键检查时用力太大将基板上的FM按键压坏2

无100% fuction check

后续功能测试工位100%检查4

SW检查治具改造,采用机械按压测试代替人手直接按压按键测试

生技完成日

期:2007/08/31

进行中

stick to wrong location assembly NG 7miss operating 2

sample control 100% double visual check 4None 贴附位置不正确

错误装配

4操作错误样品管理

100%多重目视检查

7无forget to stick cushion Poor appearance 6

miss operating 2 1.sample control 100% double visual check 4None 胶布漏贴外观不良

4

作业员疏忽

1.样品管理100%多重目视检查

7无2.qty control 2.数量管理

screw loose button ineffective 7

screw driver torque too small 2use torque meter to control check torque daily and when 4

None 螺丝松动

按键无效

螺丝刀扭力过小

torque

model changed

无

用扭力计控制扭力

每天或换机种时检查扭力

screw missing button rattle noise heard 6

miss operating 3

indicate screwing order on bezel use screw counter to control 3None 漏打螺丝按键的晃动声

操作错误

screwing jig 螺丝计数器数量管理2

无

在前咀治具上注明打螺丝的顺序

48

64

48

100% fuction check

后续功能测试工位100%检查

56

56

48

28

36

48

42

24

15. inspect SW-BD (ST-PT03)

15. SW-基板部件检验

56

54

overview NG 未检出不良(引脚连锡,电子元件损坏)check equipments at the begin of work始业点检48

28

56

48

56

emendation on equipments yearly 仪器校正每年一次equipments maintain monthly 设备的月度保养6

Co.,Ltd.

(PROCESS FMEA)

Item项目名称:

Page no.页码:共19页

Model Year/Vehicle:Responsibility责任部门:Prepared by制作:

Core Team核心小组:

Key Date关键日期:

过程项目潜在的潜在的严S 级潜在的频O 现行制程预防控制现行制程侦测措施难D R 建议的措施责任与目标效果确认Action Results

&功能要求

失效模式失效结果重E

失效原因与机理度C Current Control

Current Control

检e P Recommended 完成日期S O D R

Process Descpription Potential Potential

度V 别Potential

数C Prevention

Detection

度t N Action(s)

Res.&Tar.

采取的措施e c e P

&Process Purpose Failure Mode Effect(s) of Failure Cause(s) of Failure Completion Date Action Taken v c t N

有限公司

工 程 潜 在 的 失 效 模 式 与 效 果 分 析

C

L

A

S

S 风险

优先率 FMEA date日期(编制):

16.HARMAL&SHEET FIXING

stick to wrong location

button function failured 7

miss operating 2

jig with hole openned to avoid 100% visual check 4None 16.润滑及胶布贴附涂油位置错误

按键性能不良操作错误missing

100%目视检查8无(ST-B1)

防呆治具以预防stick to wrong location assembly NG 7miss operating 2sample control 100% visual check 4None 贴附位置不正确错误装配4操作错误

样品管理100%目视检查8无sheet leakage poor appearance 6

operator carelessness 2 1.sample control 100% visual check 4None 胶布漏贴

外观不良

4

作业员疏忽

1.样品管理100%目视检查

8

无

2.qty control 2.数量管理

17.BEZEL ASSY-1bezel scratch poor appearance 6handling carelessly 2

use plastic cover to protect 100% double visual check 4None (SCREWING PROCESS)前咀有擦伤

外观不良

4不小心掉落

用塑料盖保护前咀

100%双重目视检查

7无

17.开关基板打螺丝(ST-B2)

screw drops into bezel foreign material 6

handling carelessly 2fix cover used to cover unit 100% rattle noise check at 4assy during screwing (rattle noise)4

during screwing on screwing jig

FPA station

3

None 打螺丝时,螺丝掉进前咀

有异物(卡嗒声)

打螺丝时过失操作

在螺丝治具上安装防护盖

FPA工程100%检查

无

screw loose button ineffective 7

screw driver torque too small 2use torque meter to control check torque daily and when 4None 螺丝松动按键无效

螺丝刀扭力过小

torque

model changed

无

用扭力计控制扭力每天或换机种时检查扭力

screw missing button rattle noise heard 6miss operating 3

indicate screwing order on bezel use screw counter to control 3None 漏打螺丝按键的晃动声4操作错误

screwing jig 螺丝计数器数量管理2

无

在前咀治具上注明打螺丝的顺序

ESD destroy electrical function 8operator not wearing 2

use ESD cleaner to get rid of ESD

1.daily check before line start 2None ESD破坏

failures 7

ESD band

使用离子风机消除静电

1.每天开始生产前检查

4

无

电器性能破坏作业员没有佩带静电带 2.check ESD of operating areas 2.作业区域静电检查

SW PCB scratch NG product accured 7incoming part NG 2

None 1 100% function double check 4None 开关基板划伤

功能不良

来料不良

无

1 后续工位多重100%功能检查3无screwing hole for avoiding 1improve screwing hole of jig 1 100% function double check 4None missing too big

打螺丝治具的螺丝孔的改善 1 后续工位多重100%功能检查3

无打螺丝治具的防呆孔偏大SW PCB crack VOL button not response

82 1 100% function check 4开关基板断裂

音量旋钮无反应

7

1 后续工位100%功能检查

3

48

56

48

48

54

56

32

28

SW BD and bezel poor assemble, extrusion happening when lock screw result in the crack of SW BD

开关基板于面板没有完成组合,开关基板上的螺丝孔位和面板上的螺丝孔位没有对准,打螺丝时挤压造成开关基板断裂

None 无

64

56

56

1 add this item as important in into process sheet

1 在作业指导书追加该动作none

2 add press action after assemble SW-BD and panel

2 在开关基板和面板组合后确认是否对准

3

5

Co.,Ltd.

(PROCESS FMEA)

Item项目名称:

Page no.页码:共19页

Model Year/Vehicle:Responsibility责任部门:Prepared by制作:

Core Team核心小组:Key Date关键日期:

过程项目潜在的潜在的严S 级潜在的频O 现行制程预防控制现行制程侦测措施难D R 建议的措施责任与目标效果确认Action Results

&功能要求

失效模式失效结果重E

失效原因与机理度C Current Control

Current Control

检e P Recommended 完成日期S O D R

Process Descpription Potential Potential

度V 别Potential

数C Prevention

Detection

度t N Action(s)

Res.&Tar.

采取的措施e c e P

&Process Purpose Failure Mode Effect(s) of Failure Cause(s) of Failure Completion Date Action Taken v c t N

有限公司

工 程 潜 在 的 失 效 模 式 与 效 果 分 析

C

L

A

S

S 风险

优先率

FMEA date日期(编制):

cable can not insert into connector 连接线插不进去

LCD don't display LCD无显示

87

the plastic in connector crack连接线内部塑胶断裂

2

make checking connector fixture 作成检查插座的治具

ckeck using specialties fixture 用治具检查

2

None 无

oversight on inspection 漏检

NG parts released to product line,result in

production function fail as can't workable or instability

不良品流到生产线,造成产品功能不良

87

parts put into next station without inspection because of miss operating of operator 作业员失误,部件没有检查就流到下个工位

2dispart the checked parts and without check parts

检查过和未检查的部品分开放置if parts have checked ,will make a mark on it

在已经检查过的部品上打点确认100% fuction check

后续功能测试工位100%检查

100% visual check on parts using station

在部件的使用工位100%检验有无该标识

43

none 无

oversight NG NG parts released to 6 1 miss operating 2

qualification training on 3None 未检出不良

product line

4 1 操作失误inspection

无错误或不良品流到生产线

检查员资格培训

2 tester failure 2

3None 2 测定器失效

4

无

19.DISPLAY TO BRACKET-M LCD scratch poor appearance 6miss operating 2 1.training operator

100% double visual check 4None FIXING

LCD镜片划伤

外观不良4操作错误

1.培训作业员

100%多层目视检查

7

无19.支架胶布&显示模块与

2.stick protect sheet on LCD 支架组装(ST-B3)

2.LCD贴保护膜

dust(dirty) on LCD poor appearance 6incoming part NG 2

None 100% double visual check 4None LCD有灰尘(脏)

外观不良

4

来料不良

无

100%多层目视检查

7无stick dust in process 2

add ion gun jig

100% double visual check 4None 作业中灰尘粘附上

追加离子风枪进行吹尘100%多层目视检查

7无screw loose/tighten rattle noise heard when 6screw driver torque too small 2use torque meter to control check torque daily and when 4

None 螺丝松动或过紧

shaking due to loose 4

螺丝刀扭力过小

torque

model changed

无

松动,摇晃时有杂音

用扭力计控制扭力

每天或换机种时检查扭力

slide occurred due to 6screw driver torque too big 2

use torque meter to control check torque daily and when 4None tighten 4螺丝刀扭力过大

torque

model changed

无

过紧,滑牙

用扭力计控制扭力每天或换机种时检查扭力departure occurd between assembly NG 7can not fix bracket properly 3 https://www.sodocs.net/doc/a05366585.html,ing fixture

100% double visual check 2None screw hole of bracket and 错误装配4

due to space between bracket for fixing bracket properly,100%多层目视检查

7

无

jig's

and jig is too big

LCD与支架组装时,支架螺孔治具定位空间过大,导致支架不能 1.治具准确定位

与治具螺孔偏移

准确定位

2.trainning operator to confirm bracket was fixed well before screwing

2.教育作业员打螺丝前确认支架固定良好

48

100% fuction check

后续功能测试工位100%检查48

36

36

48

48

64

32

48

4218 inspect LCD model (ST:PT04)

18 LCD部件的检验

emendation on equipments yearly 仪器校正每年一次

equipments maintain monthly 设备的月度保养check equipments at the begin of work始业点检

2

6

Co.,Ltd.

(PROCESS FMEA)

Item项目名称:

Page no.页码:共19页

Model Year/Vehicle:Responsibility责任部门:Prepared by制作:

Core Team核心小组:

Key Date关键日期:

过程项目潜在的潜在的严S 级潜在的频O 现行制程预防控制现行制程侦测措施难D R 建议的措施责任与目标效果确认Action Results

&功能要求

失效模式失效结果重E

失效原因与机理度C Current Control

Current Control

检e P Recommended 完成日期S O D R

Process Descpription Potential Potential

度V 别Potential

数C Prevention Detection

度t N Action(s)

Res.&Tar.

采取的措施e c e P

&Process Purpose Failure Mode Effect(s) of Failure Cause(s) of Failure Completion Date Action Taken v c t N

有限公司

工 程 潜 在 的 失 效 模 式 与 效 果 分 析

C

L

A

S

S 风险

优先率 FMEA date日期(编制):

20.-KNOB preparation&Insert NG product accured 6

None 20.旋钮准备/压入不良品发生

无

(ST-B4)

overpressed

弹簧片未完全压入或压裂旋钮dented poor appearance 6knob mixed together, 2

separate each knob

visual check at visual check station 4None 有压痕

外观不良

4

friction accured

把每一个按键都单独分离出来在外观检查工位进行目视检查

无所有按键混在一起,发生摩擦foreign material inside 2clear jigs when daily work over visual check at visual check station 4None insert jig

每天下班时清洁治具

在外观检查工位进行目视检查

无压入治具有异物

black cap of power knob poor appearance 6screw missing 4

use screw counter to control visual check at visual check station 2None cap missing 外观不良4漏装螺丝

螺丝计数器数量管理在外观检查工位进行目视检查无缺少开始键的黑帽

operation inconvenient 6

black cap missing 3training operator qty control 2

None 操作不方便1

漏装黑帽培训作业员

数量管理

无button stuck poor touch feeling,7

burr on button 2

None 100% check at bezel 4None 按键卡住

botton ineffective 按键有毛边

无

assembly station

无

手感差,按键无效

前咀组装工程100%检查

fixing tune knob instead poor appearance operator mistaked part training operator visual check

4None of volume knob 外观不良6

作业员拿错部品

2

培训作业员外观治具目视检查

无

音量旋钮错装为调谐旋钮4not be completely pressed NG product occurred 6

pressure too small or too big 2None 2None or knob crack due to 不良品发生

压力过大或过小

无4

无

overpressed

未完全压入或压裂旋钮screw loose/tighten rattle noise heard when 6screw driver torque too small 2use torque meter to control check torque daily and when 4None 螺丝松动或过紧

shaking due to loose 4

螺丝刀扭力过小

torque

model changed

无

松动,摇晃时有杂音用扭力计控制扭力

每天或换机种时检查扭力slide occurred due to 6screw driver torque too big 2use torque meter to control check torque daily and when 4None tighten 4

螺丝刀扭力过大

torque

model changed

无

过紧,滑牙

用扭力计控制扭力

每天或换机种时检查扭力

button ineffective 7screw driver torque too small 2use torque meter to control check torque daily and when 4None 按键无效

螺丝刀扭力过小

torque

model changed

无

用扭力计控制扭力

每天或换机种时检查扭力

48

24

24

24

check air pressure daily 每天在工作开始时点检气压

56

48

36

check air pressure daily 每天在工作开始时点检气压48

pressure too small or too big 压力过小或过大

256

48

48

none 无

48

plate spring not be completely pressed or knob cracked due to

Co.,Ltd.

(PROCESS FMEA)

Item项目名称:

Page no.页码:共19页

Model Year/Vehicle:Responsibility责任部门:Prepared by制作:

Core Team核心小组:

Key Date关键日期:

过程项目潜在的潜在的严S 级潜在的频O 现行制程预防控制现行制程侦测措施难D R 建议的措施责任与目标效果确认Action Results

&功能要求

失效模式失效结果重E

失效原因与机理度C Current Control

Current Control

检e P Recommended 完成日期S O D R

Process Descpription Potential Potential

度V 别Potential

数C Prevention

Detection

度t N Action(s)

Res.&Tar.

采取的措施e c e P

&Process Purpose

Failure Mode Effect(s) of Failure Cause(s) of Failure Completion Date Action Taken v c t N

有限公司

工 程 潜 在 的 失 效 模 式 与 效 果 分 析

C

L

A

S

S 风险

优先率 FMEA date日期(编制):

bezel scratch poor appearance 6handling carelessly 2

use plastic cover to protect 100% check at visual check station 4

None 前咀有擦伤

外观不良

4

不小心掉落

bezel

在外观检查工程100%目视检查

无

用塑料盖保护前咀

FINAL ASSY 终组立

21.Bezel Bracket-M &mechanism screw loose/tighten rattle noise heard when 6screw driver torque too small 2use torque meter to control check torque daily and when 4None assembly

螺丝松动或过紧

shaking due to loose 4

螺丝刀扭力过小

torque

model changed

无

21.前咀&支架&机芯组装松动,摇晃时有杂音用扭力计控制扭力

每天或换机种时检查扭力( ST:FA-01)

slide occurred due to 6screwd river torque too big 2

use torque meter to control check torque daily and when 4None tighten 4

螺丝刀扭力过大

torque

model changed

无

过紧,滑牙

用扭力计控制扭力

每天或换机种时检查扭力screw drops into bezel foreign material 6handling carelessly 2

fix cover used to cover unit 100% rattle noise check at 4None assy during screwing (rattle noise)4

during screwing on screwing jig FPA station 3

无

打螺丝时,螺丝掉进前咀

有异物(卡嗒声)

装螺丝时过失操作

在螺丝治具上安装防护盖

FPA工程100%检查

screwing with wrong screw button rattle noise heard 6operator use the wrong screw 4indicate screwing order on use screw counter to control 2None 装错螺丝

按键的晃动声

4

作业员拿错

bezel screwing jig

螺丝计数器数量管理

无

在前咀打螺丝治具上注明打螺丝的顺序

AUDIO L&R out of shape poor appearance 6overpress during operating 4None 100% check at visual station 2None 左/右支架变形外观不良4操作中压力过大

无

在外观检查工程100%目视检查4无

screw high-up NG assembly 7bad matching between SW PCB 3cut the boss 100% check at visual station 2None 螺丝未完全打入

错误装配4and boss

固定柱再加工

在外观检查工程100%目视检查4无

开关基板固定柱与机芯组装不到位

机芯针脚位置偏移,与面板不能完全接触造成

功能不良

7

前咀面板与机芯组装作业时面板被以歪斜的角度组装到机芯

2作业员培训,组装时要垂直作业100% check at APT station APT工程100% 检查

4

None 无

TEST&PACKING 测试与包装22.ACDT&APT error accured,can't play output reduce 7

wrong adjustment on equipment 2carry out preventive maintenance 100% check at APT station 2None Function test 发生错误,无法播放减少产量

1

or wrong program

by engineer APT工程100% 检查3

无

22.ACDT&APT 机器调试错误或程序错误

技术工程师预防维护

性能测试( ST-FT01)

dummy connector of bezel function error 7

wrong adjustment on equipment 2carry out preventive maintenance,100% check at APT station 2None damage 功能错误or wrong program

training operator and make feed APT工程100% 检查3

无

仿真前咀接线损坏

机器调试错误或程序错误

back system

预防维护,培训作业员并反馈

channel balance NG noise from CD signal 8CD MODULE/main PCB NG 2

None 100% check at APT station 2none 信道平衡 NG CD信号有噪音7CD机芯/主机板不良

无APT工程100% 检查3

无

28

28

42

32

48

48

48

48

48

48

56

Co.,Ltd.

(PROCESS FMEA)

Item项目名称:

Page no.页码:共19页

Model Year/Vehicle:Responsibility责任部门:Prepared by制作:

Core Team核心小组:

Key Date关键日期:

过程项目潜在的潜在的严S 级潜在的频O 现行制程预防控制现行制程侦测措施难D R 建议的措施责任与目标效果确认Action Results

&功能要求

失效模式失效结果重E

失效原因与机理度C Current Control

Current Control

检e P Recommended 完成日期S O D R

Process Descpription Potential Potential

度V 别Potential

数C Prevention

Detection

度t N Action(s)

Res.&Tar.

采取的措施e c e P

&Process Purpose

Failure Mode Effect(s) of Failure Cause(s) of Failure Completion Date Action Taken v c t N

有限公司

工 程 潜 在 的 失 效 模 式 与 效 果 分 析

C

L

A

S

S 风险

优先率 FMEA date日期(编制):

total harmonic weaken CD performance 8CD MODULE/main PCB NG 2

None 100% check at APT station 2None distortion NG 减弱CD功能

7

CD机芯/主机板不良

无

APT工程100% 检查

3

无

THD NG

总谐波/THD NG

frequency response NG weaken CD performance 8CD MODULE/main PCB NG 2

None 100% check at APT station 2none (Ref=1kHz 0dB)减弱CD功能

7CD机芯/主机板不良无APT工程100% 检查

3无频率响应NG S/N ratio big noise at CD mode 8CD MODULE/main PCB NG 2None 100% check at APT station 2None 信噪比测试

CD模式噪音大

7

CD机芯/主机板不良

无APT工程100% 检查

3

无channel separation NG weaken CD performance 8CD MODULE/main PCB NG 2

None 100% check at APT station 2None 信道分离 NG 减弱CD功能7CD机芯/主机板不良

无

APT工程100% 检查3

无

FM seek stop NG cannot stop at FM station 8tuner/main PCB NG 2

None 100% check at APT station 2None FM搜索停台NG

无法锁住FM台

7

调谐器/主机板不良

无

APT工程100% 检查

3

无

FM pratical weaken FM performance 8tuner/main PCB NG 2

None 100% check at APT station 2None sensitivity NG 减弱FM功能7

调谐器/主机板不良

无APT工程100% 检查3

无FM实用敏感度NG

- 3dB limited weaken FM performance 8tuner/main PCB NG 2

None 100% check at APT station 2None sensitivity NG 减弱FM功能7调谐器/主机板不良

无

APT工程100% 检查3

无

限制灵敏度-3dB NG

FM siganl/noise ratio NG weaken FM performance 8

tuner/main PCB NG 2

None 100% check at APT station 2None FM 信噪比 NG 减弱FM功能7

调谐器/主机板不良

无APT工程100% 检查3

无

total harmonic distortion weaken FM performance 8tuner/main PCB NG 2

None 100% check at APT station 2None NG 减弱FM功能7

调谐器/主机板不良

无APT工程100% 检查3

无FM 总谐波 NG

frequency response NG weaken FM performance 8tuner/main PCB NG 2

None 100% check at APT station 2none (Ref=10kHz 0dB)减弱FM功能

7调谐器/主机板不良无APT工程100% 检查

3无频率响应NG

FM stereo separation NG poor stereo effect 8tuner/main PCB NG 2None 100% check at APT station 2None FM立体声分离NG

音响效果差

7

调谐器/主机板不良

无

APT工程100% 检查

3

无

operating voltage low radio performance NG 8power IC NG 2

None 100% check at APT station 2None 操作电压低收音功能NG 7电源IC不良

无APT工程100% 检查3

无

32

32

32

32

32

32

32

32

*

32

32

32

**32

*

*

*

7

7

7

Co.,Ltd.

(PROCESS FMEA)

Item项目名称:

Page no.页码:共19页

Model Year/Vehicle:Responsibility责任部门:Prepared by制作:

Core Team核心小组:

Key Date关键日期:

过程项目潜在的潜在的严S 级潜在的频O 现行制程预防控制现行制程侦测措施难D R 建议的措施责任与目标效果确认Action Results

&功能要求

失效模式失效结果重E

失效原因与机理度C Current Control

Current Control

检e P Recommended 完成日期S O D R

Process Descpription Potential Potential

度V 别Potential

数C Prevention

Detection

度t N Action(s)

Res.&Tar.

采取的措施e c e P

&Process Purpose

Failure Mode Effect(s) of Failure

Cause(s) of Failure Completion Date Action Taken v c t N

有限公司

工 程 潜 在 的 失 效 模 式 与 效 果 分 析

C

L

A

S

S 风险

优先率 FMEA date日期(编制):

AM seek stop cannot stop at AM station 8tuner/main PCB NG 2

None 100% check at APT station 2None sensitivity NG 无法锁住AM台

7

调谐器/主机板不良

无

APT工程100% 检查

3

无

AM 搜索停台敏感度 NG

AM pratical weaken AM performance 8tuner/main PCB NG 2

None 100% check at APT station 2None sensitivity NG 减弱AM功能7

调谐器/主机板不良无APT工程100% 检查

3无

AM实用敏感度NG

产品周边的信号干扰

3无

本工位防呆测试程序能自检测出来

2

在设备的接地线串连450mH的电感减低干扰信号生技日期:

2007/08/05完成

AM max.sensitivity NG weaken AM performance 8tuner/main PCB NG 2

None 100% check at QA station 2None AM最大限度灵敏度NG 减弱AM功能7调谐器/主机板不良

无QA工程100% 检查3

无

3dB VOL DOWN POINT

weaken AM performance 8tuner/main PCB NG 2

None 100% check at APT station 2None 减弱AM功能7调谐器/主机板不良

无APT工程100% 检查3

无

noise from AM signal big noise at AM mode 8tuner/main PCB NG 2

None 100% check at APT station 2None AM信号有噪音AM模式噪音大7

调谐器/主机板不良

无APT工程100% 检查3

无

total harmonic weaken AM performance 8tuner/main PCB NG 2

None 100% check at APT station 2None distortion NG 减弱AM功能7

调谐器/主机板不良

无APT工程100% 检查3

无

AM 总谐波 NG

output level of different function error 8

tuner/main PCB NG 2

None 100% check at APT station 2None mode NG 性能不良

7调谐器/主机板不良

无APT工程100% 检查3

无

REF mode:FM,400Hz,30%,

54dBuV

不同模式输出辐度NG tuner L/R output radio performance NG 8solder of tuner lead short 3

None 100% check at APT & FPA station 2None different

收音功能NG

7

调谐器导线焊接短路

无FPA &APT工程100%检查3

无

调谐器左右输出不同dirty or scratch on misjudgement 3disc over used 2

check disc and change it 100% visual check 4None test CD & disc 判断错误2磁盘使用次数过多

when required

100%目视检查8

无

测试盘及磁带有检查磁盘并在需要时更换

脏物或擦伤

32

32

48

32

32

32

32

24

32

*

*

*

*

48

7

7

7

Co.,Ltd.

(PROCESS FMEA)

Item项目名称:

Page no.页码:共19页

Model Year/Vehicle:Responsibility责任部门:Prepared by制作:

Core Team核心小组:

Key Date关键日期:

过程项目潜在的潜在的严S 级潜在的频O 现行制程预防控制现行制程侦测措施难D R 建议的措施责任与目标效果确认Action Results

&功能要求

失效模式失效结果重E

失效原因与机理度C Current Control

Current Control

检e P Recommended 完成日期S O D R

Process Descpription Potential Potential

度V 别Potential

数C Prevention

Detection

度t N Action(s)

Res.&Tar.

采取的措施e c e P

&Process Purpose

Failure Mode Effect(s) of Failure Cause(s) of Failure Completion Date Action Taken v c t N

有限公司

工 程 潜 在 的 失 效 模 式 与 效 果 分 析

C

L

A

S

S 风险

优先率 FMEA date日期(编制):

left channel has function error 8poor connect between FPA 2

change connect line of 100% check at APT & FPA station 2None signal,but right 性能不良

7

and load box

FPA jig

FPA &APT工程100%检查

3

无

channel no signal FPA与负载盒的连线接触不良

更换FPA治具连接线

左声道有信号,右声道没有信号

short between LCD ASSY's function error 8incoming part NG 2

1.check IQC's jig 100% check at APT & FPA station 2None ACC and ILL

性能不良7来料不良

1.IQC治具改善检查

FPA &APT工程100%检查3

无

LCD组合ACC/ILL短路

2.control power supply﹠electric current(≤4A)2.电源﹠电流限位(≤4A)AM button on bezel is poor appearance 6incoming part NG 2

trainning inspector 100% incoming inspection 2None replaced by FM button 外观不良4

来料不良

追加重点检测项目

100%受入检查

3

无

前咀面板AM键错装为FM键IQC didn't detect it 100% check in cosmcosmetic station IQC未检出

外观工位设备100%检查

23.Chamber test illumination dispiay liglt NG 7

temperature of chamber's 2

daily check and maintenance on daily check and visual check 4None 23.耐温测试flickering

显示灯不良

too high

equipment

日常点检和外观检查

无

(ST-FT02)

显示闪烁,不点灯

热炉温度过高

设备的日常点检,及保养

24.FM Inspection&ST REMOTE

total harmonic high distortion 8tuner/main PCB NG 2

None 100% check at APT station 4None 24.FM性能测试&遥控测试distort at FM mode

7调谐器/主机板不良

无APT工程100% 检查3

无

(ST-FT03)

总谐波歪曲FM模式下高度歪曲remote NG remote function 7

ST remote box fixing NG 2

check st remote daily 100% check at FPA station 4None 遥控NG

ineffective ST remote box设置错误生产线每天检查

FPA工程100% 检查

3无遥控性能无效

Cable defect 2Check cable and change 100% check at FPA station 4None due to over use

cable when required FPA工程100% 检查

3

无

由于过度使用电缆损坏

需要时,检查及更换电缆

operating voltage low radio performance NG 8power IC NG 2

None 100% check at FPA station 4None 操作电压低

收音功能NG 7电源IC不良

无

FPA工程100% 检查

3无ANT output less than 8.2V function error 8ANT output short,

2治具连接线屏蔽,ANT出力100% check at FPA station 4None ANT 输出<8.2V 性能不良

7

electric current too big 检查以外工程ANT&线去除FPA工程100% 检查

3

无

ANT输出短路,电流大造成

hide connector of jig,get rid of ANT& cabels beside ANT output station ESD destroy

2

check ESD daily

100% check at FPA station 3None ESD破坏

生产线静电点检

FPA工程100% 检查

无

48

64

64

32

64

56

56

32

24

56

4

7

Co.,Ltd.

(PROCESS FMEA)

Item项目名称:

Page no.页码:共19页

Model Year/Vehicle:Responsibility责任部门:Prepared by制作:

Core Team核心小组:

Key Date关键日期:

过程项目潜在的潜在的严S 级潜在的频O 现行制程预防控制现行制程侦测措施难D R 建议的措施责任与目标效果确认Action Results

&功能要求

失效模式失效结果重E

失效原因与机理度C Current Control

Current Control

检e P Recommended 完成日期S O D R

Process Descpription Potential Potential

度V 别Potential

数C Prevention

Detection

度t N Action(s)

Res.&Tar.

采取的措施e c e P

&Process Purpose

Failure Mode Effect(s) of Failure

Cause(s) of Failure Completion Date Action Taken v c t N

有限公司

工 程 潜 在 的 失 效 模 式 与 效 果 分 析

C

L

A

S

S 风险

优先率 FMEA date日期(编制):

FM seek stop NG cannot stop at FM station 8antenna cable ineffective 2

check cable and change it 100% check at FPA station 4None FM搜索停台NG

无法锁住FM台

7

due to over used

when required

FPA工程100% 检查

3

无

由于过度使用,天线失效需要时,检查及更换电缆seek sensitivity weakened 2

制造39dBuVemf/60~66℃检查100% check at FPA station 4None after chamber

不良品QA性能测试40℃确认

FPA工程100% 检查3

无

经过热炉后主机搜索敏感度降低

test under 39dBuVemf/60~66℃,

confirm NG set under 40℃ by QA

25.External CD changer&dirty/scratch on test CD misjudgement 3

disc over used 2

check disc and change it 100% check at FPA station 4None Illumi,4 spk & mecha noise,测试光碟有污物及划伤判断错误2磁盘使用次数过多

when required

FPA工程100% 检查3

无

RPT,RDM

检查磁盘并在需要时更换

25.外接多碟箱测试&亮度及4-SPK测试,RPT,RDM

(ST-FT04)

LCD display dim function error 7

CD-CH incoming NG(voltage low)2 1.sample control 100% check at FPA station 4None LCD显示模块灯光暗

错误功能

机芯来料不良(电压偏低)

1.样品管理

FPA工程100% 检查3

无

2.check voltage by IQC when coming

2.IQC受入电压测试

taint is visible from poor appearance 6incoming bezel NG 2

1.make limited sample 100% check at FPA station 4None 无

bezel's reflector 外观不良

4

前咀面板来料不良

1.标准限度确认与样本制作FPA工程100% 检查

3

前咀面板跑马灯有污点

2.trainning inspectors and workers

2.IQC&PR检查员的教育

white shadow is visible poor appearance 62

1.make limited sample 100% check at FPA station 4None 无

from bezel's reflector 外观不良4

1.标准限度确认与样本制作FPA工程100% 检查3

前咀面板跑马灯透白光

2 training workers 2 IQC&PR检查员的教育

26.AM Inspection

AM seek stop NG cannot stop at AM station 8signal generator wrong setting 2check signal generator daily 100% check at FPA station 4None 26.AM性能测试AM搜索停台NG 无法锁住AM台7

信号发生器设置错误每天检查信号发生器FPA工程100% 检查

3无(ST-FT05)

Antenna cable defect 2

Check cable and change 100% check at FPA station 4None due to over used

cable when required FPA工程100% 检查

3

无

由于过度使用,天线失效

需要时,检查及更换电缆

operating voltage low Radio Performance NG 8power IC NG 2

None 100% check at FPA station 4None 操作电压低收音功能NG 7电源IC不良

无FPA工程100% 检查3

无

24

64

64

64

64

64

incoming bezel NG

跑马灯内红色胶质与透明胶棒之间有液状物,前咀面板来料不良,

56

48

48

*

*

4

Co.,Ltd.

(PROCESS FMEA)

Item项目名称:

Page no.页码:共19页

Model Year/Vehicle:Responsibility责任部门:Prepared by制作:

Core Team核心小组:Key Date关键日期:

过程项目潜在的潜在的严S 级潜在的

频O 现行制程预防控制现行制程侦测措施难D R 建议的措施责任与目标效果确认Action Results

&功能要求

失效模式失效结果重E

失效原因与机理度C Current Control

Current Control

检e P Recommended 完成日期S O D R

Process Descpription Potential Potential

度V 别Potential

数C Prevention

Detection

度t N Action(s)

Res.&Tar.

采取的措施e c e P

&Process Purpose Failure Mode

Effect(s) of Failure

Cause(s) of Failure Completion Date Action Taken v c t N

有限公司

工 程 潜 在 的 失 效 模 式 与 效 果 分 析

C

L

A

S

S

风险

优先率 FMEA date日期(编制):

27.CAN ANALYZER&ERROR software setting wrongly 1 misjudgement 3operator carelessness 2

check software 100% check at FPA station 4None CODE CLEAN

软件设置错误 1 判断错误

2

操作员过失

when model changed FPA工程100% 检查

3

无

27.CAN及ERROR清除更换机种时检查软件

(ST-FT05)

2 LCD no display 2 LCD无显示87

the software'Ver of LCD is well contol ,the

communication between design and plant

LCD中的软件的版本没有管控好,设计和生产之间沟通不到位(详见8D报告 编号CQS-8D-007)2

defind software and Ver as parts to manage 软件及其版本作为部件进行管理(详见8D报告 编号CQS-8D-007)

100% function check FPA工程100% 检查43

None 无

LCD Ver.test:

function error 7

poor connection between set 2

https://www.sodocs.net/doc/a05366585.html,e auto switch 100% check at FPA station 4None display “None ACU”功能不良

and jig

1.追加按键式自动开关

FPA工程100% 检查3

无

LCD Ver.测试:产品与治具接触不良

2.check anchor point of jigs 显示None ACU

monthly

2.治具月检定位

28.Indash CD changer dirty/scratch on test CD misjudgement 3disc over used

2check disc and change it 100% check at FPA station 4None INSPECTION 测试光碟有污物及划伤判断错误

2磁盘使用次数过多

when required

FPA工程100% 检查3

无

28.多DISC测试检查磁盘并在需要时更换(ST-FT06)

error code 06ER078dirty on test CD 2check disc and change it 100% check at FPA station 2None 误码 06ER077测试光碟有污物when required

FPA工程100% 检查3

无

检查磁盘并在需要时更换

check disc before start作业前对光碟进行点检

https://www.sodocs.net/doc/a05366585.html,bi test,BAL/FAD dirty/scratch on test CD misjudgement 3

disc over used 2

check disc before line start, 100% check at FPA station 4None INSPECTION

测试光碟有污物及划伤判断错误2磁盘使用次数过多

clean them weekly and change FPA工程100% 检查3

无

29.暗电流测试及错误确认when required

(ST-FT07)

作业前检查测试碟,周期性(周/次)清洁测试碟并在必要时更换

dark current is too big function error 8incoming parts NG 2

Add check on dark current of 100% check at FPA station 4None 暗电流大性能不良7

来料不良

main/display PCB to check FPA工程100% 检查3

无

items of IQC

IQC追加Main/Display PCB暗电流检查

功能测试时,交流电压表指针无反应

产品误判7

治具上固定天线的螺丝松动,导至FPA治具上的天线位置往后移,造成产品与治具上的天线接触不充分

2治具的月度保养

100% check at FPA station FPA工程100% 检查

3 1 追加一螺丝固定天线2 治具的月度点检追加用六角扳手固定该螺丝的动作

生技日期:2007/08/02完成30.CD combi vibration dirty/scratch on test CD misjudgement 3

disc over used 2check disc before line start, 100% check at FPA station 4None 30.振动测试及错误再确认测试光碟有污物及划伤判断错误2

磁盘使用次数过多

clean them weekly and change FPA工程100% 检查

3

无

(ST-FT08)

when required

作业前检查测试碟,周期性(周/次)清洁测试碟并在必要时更换

music jumpping music skip 5

vibration machine setting 2

check vibration machine daily Check per shift 4None 音乐跳动跳过歌曲

wrongly

每天检查振动机器

每班一次设备点检

3无振动机器设置错误CD load/eject not steady function error 7

cd- incoming NG 2

None 100% check at FPA station 4None 进出碟不稳定功能不良机芯来料不良

无

FPA工程100%检查

3无can not choose track function error 7aseismatic function of mech 2 1.revise standard:100% check at FPA station 4None CD不能选曲

功能不良

not enough

1.修正作业标准:

FPA工程100%检查

3

无

机芯耐振性不足

a.acceleration of vibration: change 1.7G to 2.0G

a.振动测试重力加速度由1.7G 变更为2.0G

b.revise order of vibration test:

before:vibration on→TRACK 20after:TRACK 20→vibration on b.振动测试顺序变更:

"先振动再选择TRACK 20"变更为:先选择TRACK 20再振动2.revise process sheet 2.修订作业指导书3.trainning operator 3.指导作业员操作

64

24

24

32

56

56

24

40

56

24

64

*

56

1

3

6

Co.,Ltd.

(PROCESS FMEA)

Item项目名称:

Page no.页码:共19页

Model Year/Vehicle:Responsibility责任部门:Prepared by制作:

Core Team核心小组:Key Date关键日期:

过程项目潜在的潜在的严S 级潜在的频O 现行制程预防控制现行制程侦测措施难D R 建议的措施责任与目标效果确认Action Results

&功能要求

失效模式失效结果重E

失效原因与机理度C Current Control

Current Control

检e P Recommended 完成日期S O D R

Process Descpription Potential Potential

度V 别Potential

数C Prevention

Detection

度t N Action(s)

Res.&Tar.

采取的措施e c e P

&Process Purpose Failure Mode Effect(s) of Failure

Cause(s) of Failure Completion Date Action Taken v c t N

有限公司

工 程 潜 在 的 失 效 模 式 与 效 果 分 析

C

L

A

S

S

风险

优先率 FMEA date日期(编制):

31.screw tightening screw tighten bezel cracked due to tighten 7screw driver torque too big 2

use torque meter to control check torque daily and when 4

None 31.螺丝紧固作业螺丝过紧

前咀破损螺丝刀扭力过大

torque

model changed

无(ST-FA02)

用扭力器控制扭力

每天或换机种时检查扭力32.Visual Inspection can not pass poor appearance 6 1.depature on position of 2confirm specs of words that 100% double visual check 2None 32.目视检查visual system

外观不良

placing product

easy to mistake

100%目视检查7无( ST-FT09)

外观检查系统测试不通过

misjudgement 2

1.主机放置位置有偏移

重点确认容易误判的文字点的规格误判

2.select test program wrongly 3confirm model program before daily check 2None 2.测试程序选择错误

operation

日常点检

4

无

作业前确认机种程序33.Visual Inspection-1label missing poor appearance 6operator carelessness 3

parts qty control 100% visual check 2None 33.外观检查标签漏贴

外观不良4操作员过失部品数量管理

100%目视检查

无( ST-FT10)

bezel panel scratched poor appearance 6miss operating 2

1.add sticking protect sheet 100% double visual check 4None 面板划伤

外观不良

4

操作中造成

before bezel flow in line 100%目视检查

7

无

1.面板投入前追加保护膜贴附

2.forbid QA inspector to wear ESD band and watch,etc 2.QA检查员禁止戴静电手腕和手表等其他手饰

incoming parts NG 2

change part and add sticking 100% double visual check 2None 来料不良

protect sheet at B1 station

100%双重目视检查7

无

更换部品,并在B1工程追加贴保

护膜rear screw of cd-ch 's loose

parts fall off 7

incoming parts NG 2

None 100% double visual check 2None 机芯尾部螺丝松动部品脱落来料不良

无

100%双重目视检查

7无serious friction on poor appearance 6friction between FPA jig and

2improve FPA jig 100% double visual check 4None cushion

外观不良

4

product

FPA治具改造

100%双重目视检查

7

无

绒布磨擦严重

FPA治具摩擦wastepaper in connector poor appearance 6miss operating 2

training operator 100% double visual check 4None 连接线接口有纸屑外观不良4作业疏忽

培训作业员

100%双重目视检查

7无not tear off control poor appearance 6

not note station that tearing 2note the station which 100% double visual check 4None label

外观不良

4

off label on process sheet tearing off label station 100%双重目视检查

8

无

产品控制标签未撕作业指导书上无指明撕标签工位on process sheet

作业指导书指定撕标签工位missing stick cushion poor appearance 6

missing operator 2

1.training operator 100% double visual check 4None 胶布漏贴

外观不良

4

作业员疏忽

1.培训作业员100%双重目视检查8

无

2.sample manager 2.样品管理

screw high-up poor appearance 6operator oversight 2

training operator 100% double visual check 4None 螺丝未完全打入外观不良4

作业员漏检

培训作业员

100%双重目视检查8

无

48

36

56

48

24

24

36

48

48

48

48

28

Co.,Ltd.

(PROCESS FMEA)

Item项目名称:

Page no.页码:共19页

Model Year/Vehicle:Responsibility责任部门:Prepared by制作:

Core Team核心小组:

Key Date关键日期:

过程项目潜在的潜在的严S 级潜在的频O 现行制程预防控制现行制程侦测措施难D R 建议的措施责任与目标效果确认Action Results

&功能要求

失效模式失效结果重E

失效原因与机理度C Current Control

Current Control

检e P Recommended 完成日期S O D R

Process Descpription Potential Potential

度V 别Potential

数C Prevention Detection

度t N Action(s)

Res.&Tar.

采取的措施e c e P

&Process Purpose

Failure Mode Effect(s) of Failure Cause(s) of Failure Completion Date Action Taken v c t N

有限公司

工 程 潜 在 的 失 效 模 式 与 效 果 分 析

C

L

A

S

S 风险

优先率 FMEA date日期(编制):

double click heard

handle NG 2incoming bezel NG 5

IQC changed the method of 100% double handle check 6None when pressing seek stop 手感不良

4

面板来料不良

inspection:100%多层按键检查7

无

button(∧&∨)

press∧and∨when checking button 按前咀面板上下搜索键时IQC变更检查方法:检查按键时,按键声音偏大

按∧,∨键确认

34.Packing impacting poor appearance 6operator carelessness 3

stick protect sheet on 100%QA visual check 3None 34.包装碰撞外观不良4操作员过失

2packing jig

100%QA外观检验8无( ST-PK01)

在包装治具上贴保护胶

lack or missing on packing lack on shipment quantity 7

operator carelessness 2

1.operating according to the num check 3None 少装或漏装(36台/卡板)出货数量不足

作业员疏忽

process sheet

多层数量检查6

无

1.作业员按照作业指导书作业part NO check

2.carry out quantity control 编号对照检查

2.实施数量管理

Reparation 修理

35.Reparation station ESD damage electrical function 8mender not wearing 2

use ESD equipment to clear ESD check ESD before repair 2None 35.修理工程

ESD破坏

failured 7

ESD band

使用离子风机消除静电

修理前的ESD检查4

无

电器性能破坏

修理员没有佩带静电带NG part after repaired result in NG product 6not mark the part repaired 2

1.reparation rule 100% double visual check 4None released to product line 导致不良产品发生4

修理品未作标识

1.修理作业规定

100%多层目视检查7

无

修理不良品误流入生产线

2.put the part repaired back to line by the person specially assigned for material

2.修理后的部品由配料员重新投入not record reparation can not trace repaired 4 1.not mark the part repaired 3

1.reparation rule confirm reparation report daily 4None 修理未记录

part

1无

修理品不可追溯

修理品再投入混料NG assembly 7not mark the part repaired 2

reparation rule 100% visual check before assembly 4None mix repaired part when 装配错误4修理品未作标识

修理作业规定

作业前100%目视检查无

released to product line

100%功能测试

1.修理员疏忽

1.培训修理员

每天修理报告的确认

32

48

56

54

60

48

42

6

Co.,Ltd.

(PROCESS FMEA)

Item项目名称:

Page no.页码:共19页

Model Year/Vehicle:Responsibility责任部门:Prepared by制作:

Core Team核心小组:Key Date关键日期:

过程项目潜在的潜在的严S 级潜在的频O 现行制程预防控制现行制程侦测措施难D R 建议的措施责任与目标效果确认Action Results

&功能要求

失效模式失效结果重E

失效原因与机理度C Current Control

Current Control

检e P Recommended 完成日期S O D R

Process Descpription Potential Potential

度V 别Potential

数C Prevention Detection

度t

N Action(s)

Res.&Tar.

采取的措施e c e P

&Process Purpose Failure Mode Effect(s) of Failure Cause(s) of Failure Completion Date Action Taken v c t N

有限公司

工 程 潜 在 的 失 效 模 式 与 效 果 分 析

C

L

A

S

S 风险

优先率

FMEA date日期(编制):

Delivery出荷

36. Pre-Delivery mixed model wrong model delivered 8mistake by inspector 2

explanation method on according to the rule of controlling 3None Inspection ( QA&PDI )弄混机种

to customer

7during inspection cross inspection mixing package 无36.装货前检查客户收到错误机种检查员检查时拿错指导交叉检查方法依照混装控制过程

( QA&PDI )

FM stereo separation NG FM立体声分离NG(1KHz)poor stereo effect 音响效果差

87tuner/main PCB NG 调谐器/主机板不良2none 无100% check at PDI station PDI工程100% 检查24None 无frequency respons NG (Ref=60Hz)

FM 频率响应 NG weaken FM performance 减弱FM功能

87tuner/main PCB NG 调谐器/主机板不良2

none 无100% check at PDI station PDI工程100% 检查

24None 无frequency respons NG (Ref=100Hz)FM 频率响应 NG weaken FM performance 减弱FM功能

87

tuner/main PCB NG 调谐器/主机板不良

2none 无

100% check at PDI station PDI工程100% 检查

24

None 无oversight inspection products released to 7

mistake by inspector 2

explanation method on record serial number &4None 漏检

customer without fully during inspection cross inspection stamp on label

无

inspected

检查员检查时拿错

指导交叉检查方法序列号的纪录并在标签上盖章

客户收到检查没到位的产品

37.Shipment excessive loading on outer carton dented or crack 7

excessive loading over 2

test endure level of pallet shiping within max endure level of 2None 37.出货pallet caused quality NG endure level of pallet and product

pallet and product

无

卡板过量堆积

外包装损坏导致产品and product

测量卡板及产品的承压能力

装货时参考卡板及产品的最大品质不良

卡板堆积超过产品及卡板的承压能力限制指示

最大承压能力

qty missing during not enough qty released to 7

missing pakage by warehouseman 2

warehouseman check packing list

2None

shipping customer

when paking when packing 无

装货时漏装

客户收到的数量不够

仓管员打包时少装

使用规范包装便于目视检查

仓管员打包时核对装箱单

*48

56

32

**

28

use standard package method that easy to check 32

28

327

相关文档

- 潜在失效模式及后果分析(TS16949)

- FMEA潜在失效模式及分析标准表格模版(1)

- 潜在失效模式及后果分析(FMEA)控制程序

- 潜在失效模式与后果分析

- 潜在失效模式及后果分析(DFMEA)

- FEMA潜在失效模式及分析知识讲解

- 潜在失效模式及其后果分析(FMECA)

- 潜在失效模式及后果分析控制程序

- 制程潜在失效模式和影响分析

- 潜在失效模式及后果分析(FMEA)控制程序

- 潜在失效模式及影响分析

- FMEA潜在失效模式及分析标准表格模版

- 潜在失效模式及其后果分析 (FMECA)

- FMEA潜在失效模式及分析标准表格模版

- 潜在失效模式及后果分析(DFMEA)

- 过程潜在失效模式及后果分析(PFMEA)样板

- 潜在失效模式分析-实例

- FMEA潜在失效模式及分析

- 潜在失效模式及效应分析.ppt

- 潜在失效模式和后果分析