New flow boilling heat transfer model and flow pattern map for carbon dioxide evaporating

New ?ow boiling heat transfer model and ?ow pattern map for carbon dioxide evaporating inside horizontal tubes

Lixin Cheng

a,b

,Gherhardt Ribatski a ,Leszek Wojtan a ,John R.Thome

a,*

a

Laboratory of Heat and Mass Transfer (LTCM),Faculty of Engineering Science (STI),E

′cole Polytechnique Fe ′de ′rale de Lausanne (EPFL),CH-1015Lausanne,Switzerland

b

Institute of Process Engineering,University of Hannover,Callinstra?e 36,30167Hannover,Germany

Received 8June 2005;received in revised form 24March 2006

Available online 5June 2006

Abstract

A new ?ow boiling heat transfer model and a new ?ow pattern map based on the ?ow boiling heat transfer mechanisms for horizontal tubes have been developed speci?cally for CO 2.Firstly,a nucleate boiling heat transfer correlation incorporating the e?ects of reduced pressure and heat ?ux at low vapor qualities has been proposed for CO 2.Secondly,a nucleate boiling heat transfer suppression factor correlation incorporating liquid ?lm thickness and tube diameters has been proposed based on the ?ow boiling heat transfer mechanisms so as to capture the trends in the ?ow boiling heat transfer data.In addition,a dryout inception correlation has been developed.Accord-ingly,the heat transfer correlation in the dryout region has been modi?ed.In the new ?ow pattern map,an intermittent ?ow to annular ?ow transition criterion and an annular ?ow to dryout region transition criterion have been proposed based on the changes in the ?ow boiling heat transfer trends.The ?ow boiling heat transfer model predicts 75.5%of all the CO 2database within ±30%.The ?ow boiling heat transfer model and the ?ow pattern map are applicable to a wide range of conditions:tube diameters (equivalent diameters for non-circular channels)from 0.8to 10mm,mass velocities from 170to 570kg/m 2s,heat ?uxes from 5to 32kW/m 2and saturation temper-atures from à28to 25°C (reduced pressures from 0.21to 0.87).ó2006Elsevier Ltd.All rights reserved.

Keywords:Model;Flow boiling;Heat transfer;Flow map;Flow patterns;Flow regimes;CO 2

1.Introduction

Carbon dioxide (CO 2or R744)has been receiving renewed interest as an e?cient and environmentally safe refrigerant in a number of applications,including mobile air conditioning,heat pump systems and hot water heat pumps in recent years [1–4].Due to its low critical temper-ature (T crit =31.1°C)and high critical pressure (p crit =73.8bar),CO 2is utilized at much higher operating pres-sures compared to other conventional refrigerants.The higher operating pressures result in high vapor densities,very low surface tensions,high vapor viscosities and low

liquid viscosities and thus yield ?ow boiling heat transfer and two-phase ?ow characteristics that are quite di?erent from those of conventional refrigerants.High pressures and low surface tensions have major e?ects on nucleate boiling heat transfer characteristics and previous experi-mental studies have suggested a clear dominance of nucle-ate boiling heat transfer even at very high mass velocity.Therefore,CO 2has higher heat transfer coe?cients than those of conventional refrigerants at the same saturation temperature and the available heat transfer correlations generally underpredict the experimental data of CO 2.In addition,previous experimental studies have demonstrated that dryout may occur at moderate vapor quality in CO 2?ow boiling,particularly at high mass velocity and high temperature conditions.Signi?cant deviations for the ?ow patterns of CO 2compared with the ?ow pattern maps that

0017-9310/$-see front matter ó2006Elsevier Ltd.All rights reserved.doi:10.1016/j.ijheatmasstransfer.2006.04.003

*

Corresponding author.Tel.:+41216935981;fax:+41216935960.E-mail addresses:lixincheng@https://www.sodocs.net/doc/b84172836.html, (L.Cheng),john.thome @ep?.ch (J.R.Thome).

https://www.sodocs.net/doc/b84172836.html,/locate/ijhmt

International Journal of Heat and Mass Transfer 49(2006)

4082–4094

were developed for other?uids at lower pressures have been observed as well.

In order to design evaporators for these thermal systems e?ectively,it is very important to understand and predict the?ow boiling heat transfer and two-phase?ow charac-teristics of CO2inside horizontal tubes.A lot of studies on?ow boiling and two-phase?ow of CO2have been car-ried out in recent years to explore the fundamental aspects with respect to the characteristics of heat transfer and two-phase?ow of CO2.Thome and Ribatski[5]have recently given a review of?ow boiling heat transfer and two-phase ?ow of CO2in the literature.The review addresses the extensive experimental studies on heat transfer and two-phase?ow in macro-channels[6–15]and micro-channels [12,16–25],macro-and micro-scale heat transfer prediction methods for CO2[12–14,26]and comparisons of these methods to the experimental database.In addition,the study of CO2two-phase?ow patterns[13,14,22,23,25]are summarized and compared to some of the leading?ow pat-tern maps in their review.Taking into account the lack of a well-established criterion to identify macro-and micro-scale channels,Thome and Ribatski[5]arbitrary adopted a hydraulic diameter of3mm to segregate the databases and heat transfer models.They found that the prediction methods by[12–14]failed to predict most of macro-scale experimental data while the method proposed by Thome and El Hajal[26]for CO2predicted reasonably well the macro-scale database of CO2at low vapor qualities.They also found that small diameter data were poorly predicted by either micro-scale or macro-scale predictive methods. Based on the results for macro-scale diameters,Thome and Ribatski suggested that the method of Thome and El Hajal should be further updated to include CO2e?ects on the annular to mist?ow in order to more accurately pre-dict heat transfer coe?cients at moderate/high vapor qual-ities.Based on this recent and comprehensive review that is recommended as a reference study,a section describing the previous studies was judged as unnecessary in this paper and the literature concerning CO2studies is presented in this text just when required to the development of the heat transfer model.

In the present study,the objectives are to develop a new general heat transfer prediction method and a new?ow pattern map especially for CO2,which covers channel

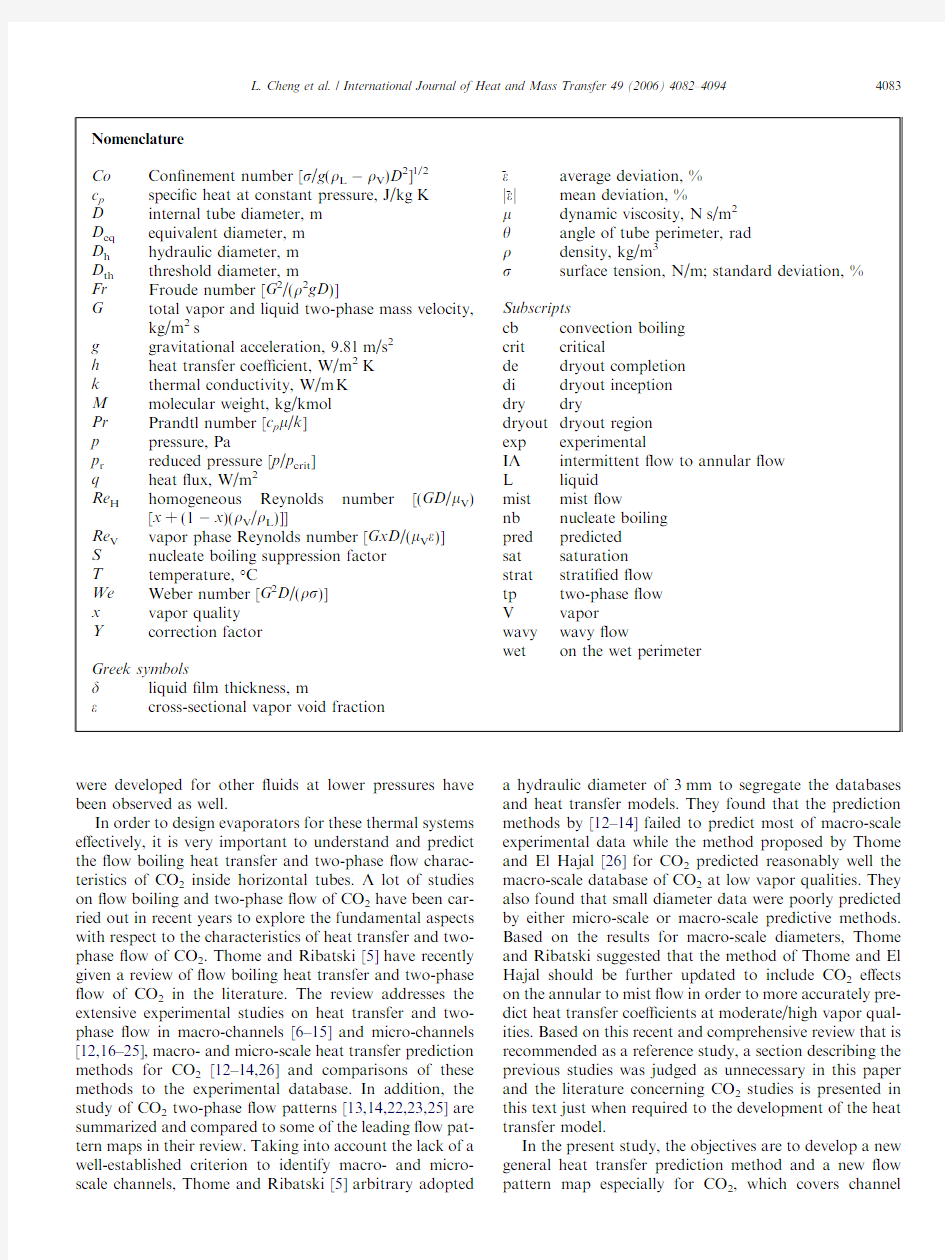

Nomenclature

Co Con?nement number[r/g(q Làq V)D2]1/2

c p speci?c heat at constant pressure,J/kg K

D internal tube diameter,m

D eq equivalent diameter,m

D h hydraulic diameter,m

D th threshold diameter,m

Fr Froude number[G2/(q2gD)]

G total vapor and liquid two-phase mass velocity,

kg/m2s

g gravitational acceleration,9.81m/s2

h heat transfer coe?cient,W/m2K

k thermal conductivity,W/m K

M molecular weight,kg/kmol

Pr Prandtl number[c p l/k]

p pressure,Pa

p r reduced pressure[p/p crit]

q heat?ux,W/m2

Re H homogeneous Reynolds number[(GD/l V) [x+(1àx)(q V/q L)]]

Re V vapor phase Reynolds number[GxD/(l V e)]

S nucleate boiling suppression factor

T temperature,°C

We Weber number[G2D/(qr)]

x vapor quality

Y correction factor

Greek symbols

d liquid?lm thickness,m

e cross-sectional vapor void fraction e average deviation,%

j e j mean deviation,%

l dynamic viscosity,N s/m2

h angle of tube perimeter,rad

q density,kg/m3

r surface tension,N/m;standard deviation,% Subscripts

cb convection boiling

crit critical

de dryout completion

di dryout inception

dry dry

dryout dryout region

exp experimental

IA intermittent?ow to annular?ow

L liquid

mist mist?ow

nb nucleate boiling

pred predicted

sat saturation

strat strati?ed?ow

tp two-phase?ow

V vapor

wavy wavy?ow

wet on the wet perimeter

L.Cheng et al./International Journal of Heat and Mass Transfer49(2006)4082–40944083

diameters found in most of CO2?ow boiling applications. Experimental conditions of studies on?ow boiling of car-bon dioxide covered by this study are summarized in Table 1.It includes experimental results obtained for mass veloc-ities from80to570kg/m2s,heat?uxes from5to32.06kW/ m2,saturation temperatures fromà28to25°C(the corre-sponding reduced pressures are from0.21to0.87)and tube diameters from0.8to10.06mm.All those experiments were conducted in horizontal tubes.Therefore,at this point,one very important issue must be clari?ed about the distinction between macro-and micro-channels?rst.Although a uni-versal agreement to distinguish between macro-and micro-channels is not as yet clearly established,the present study covers both macro-and micro-(mini)-channels according to various criteria[27,28].Based on engineering practice and application areas,Kandlikar[27]proposed using the following threshold diameters:conventional chan-nels,D h>3mm;minichannels,D h between200l m and 3mm;and micro-channels,D h between10l m and 200l m.Based on the con?nement of bubble departure sizes in channels,Kew and Cornwell[28]proposed an approxi-mate physical criterion for macro-to micro-channel thresh-old diameter as follows:

D th?

4r

geq

L

àq VT

1=2

e1T

When hydraulic diameters are larger than the threshold diameter,the channels are de?ned as macro-scale channels. When hydraulic diameters are smaller than the threshold diameter,the channels are de?ned as micro-scale channels. The test conditions of the present selected database(see Table1)are compared to these two criteria in Fig.1. Unlike the?xed values for the threshold diameters de?ned by Kandlikar,the threshold diameters based on Con?ne-ment number decrease with increasing reduced pressure and they vary from2.3mm at low reduced pressures to

Table1

The database of?ow boiling heat transfer of CO2

Data source Channel con?guration

and material D h(mm)T sat(°C)p r G(kg/m2s)q(kW/m2)Data points Heating

method

Knudsen and Jensen[7]Single circular tube,

stainless steel 10.06à280.21808,1316Heated by

condensing

R22vapor

Yun et al.[9]Single circular tube,

stainless steel 650.54170,240,34010,15,2053Electrical

heating 100.61

Yoon et al.[14]Single circular tube,

stainless steel 7.3500.4731812.5,16.4,18.6127Electrical

heating

50.54

100.61

150.69

200.78

Koyama et al.[16]Single circular tube,

stainless steel 1.80.30.47250,26032.0636Electrical

heating 100.61

10.90.62

Pettersen[20]Multi-channel with25

circular channels,

aluminium 0.800.47190,280,380,5705,10,15,2046Heated by

water 100.61

200.78

250.87

Yun et al.[21]a Multi-channels with

rectangle channels 1.14(2.7)50.54200,300,40010,15,2056Electrical

heating 1.53(3.08)

1.54(3.21)

a Material is not mentioned in the paper and the values in the parentheses are equivalent diameters.

4084L.Cheng et al./International Journal of Heat and Mass Transfer49(2006)4082–4094

0.7mm at high reduced pressures.According to Kandli-kar’s criteria,the test conditions include both conventional and mini-channels but not micro-channels.According to the criteria based on Con?nement number,Co,the test conditions mostly include macro-channels with a few micro-channels.Here,it is important to highlight the fact that the macro-to-micro transition should be identi?ed by distinction in the heat transfer,pressure drop and?ow pat-terns behaviors instead of?xed tube diameter ranges de?ned according to the applications.Therefore,the fact that,according to the available transition criteria,the proposed model covers both macro-and micro-(mini)-channels is perfectly reasonable since a threshold diameter based on the analysis of the heat transfer behavior of the present database was not identi?ed.

In the present study,a new general heat transfer model and a new?ow pattern map physically related to the heat transfer mechanisms based on a selected database from the literature were developed specially for CO2.As the starting point,the model developed by Wojtan et al. [29,30]which is an updated version of the Kattan–Thome–Favrat?ow pattern map and?ow boiling heat transfer model[31–33]was used.The new proposed predic-tion method includes new correlations for the nucleate boil-ing heat transfer and the suppression factor based on CO2 experimental data.In addition,a dryout inception vapor quality correlation was proposed for CO2and accordingly the heat transfer correlation in the dryout region was obtained.Based on the heat transfer mechanisms,a new ?ow patterns map was proposed and thus can physically explain the heat transfer phenomena according to the?ow regimes de?ned by the new?ow map.

2.CO2?ow boiling heat transfer database and comparisons 2.1.Selection of CO2?ow boiling heat transfer data

Six independent experimental studies from di?erent lab-oratories have been carefully selected to form the present database for?ow boiling heat transfer of CO2.They are the experimental data of Knudsen and Jensen[7],Yun et al.[9],Yoon et al.[14],Koyama et al.[16],Pettersen [20]and Yun et al.[21].The detailed test conditions of the database are summarized in Table1.The test channels include single circular channels and multi-channels with circular and rectangle channels at a wide range of test con-ditions,by electrical heating or?uid heating.The data were taken from tables where available or by digitizing the heat transfer graphs in these publications to extract the plotted heat transfer coe?cients.All together,334heat transfer data points including heat transfer data in the dryout region were obtained.

In order to develop a general?ow boiling heat transfer prediction model,extensive comparisons of the data avail-able in the literature have been made.However,some of the data available have not been selected due to various reasons.For example,the data of Bredesen et al.[6]for a 7mm inside diameter tube have been excluded because they di?er signi?cantly from comparable data for6mm and10.06mm inside diameter tubes in two other studies and also because there is a large scatter among their data. Hwang et al.[34]also noted an anomaly in the[6]data at a mass velocity of300kg/m2s when correlating them.Yet, since their tests were run with the same rigor as the other tests,it is not clear where these problems come from. Also,the data of Huai et al.[17]have been excluded because the available correlations overpredict their data as indicated in their study,which contradicts the general conclusion that the available correlations underpredict experimental CO2data.It is unclear why they obtained the opposite trend.

In the present study,the physical properties of CO2have been obtained from REFPROP of NIST[35].For non-cir-cular channels,equivalent diameters rather than hydraulic diameters were https://www.sodocs.net/doc/b84172836.html,ing equivalent diameter gives the same mass velocity as in the non-circular channel and thus correctly re?ects the mean liquid and vapor velocities, something using hydraulic diameter does not.

2.2.Analysis of the?ow boiling heat transfer data in the database

Although some anomalous data have already been excluded as pointed out earlier,the heat transfer data in the database show still some di?erent behaviors at similar test conditions.Fig.2(a)shows two opposite heat transfer characteristics with saturation temperature in the studies of Pettersen[20]and Yoon et al.[14].The heat transfer coef-?cients increase with the increasing saturation tempera-tures in the study of Pettersen while they decrease in the study of Yoon et al.The only big di?erence between the two studies is the diameters of the test channels as indicated in Fig.2(a).Fig.2(b)shows the comparison of the heat transfer coe?cients of Pettersen[20]to those of Koyama et al.[16].The biggest di?erence between them is that in Koyama et al.the heat?ux is32.06kW/m2while in Petter-sen is10kW/m2.The heat transfer coe?cients fall o?at the vapor quality of about0.7in the study of Pettersen while the heat transfer coe?cients increase even at qualities lar-ger than0.7in the study of Koyama et al.It is di?cult to explain why the heat transfer coe?cients fall o?at the lower heat?ux in one study while they still increase at the higher heat?ux in the other study.This could be an e?ect of the heating methods or multi-channel vs.single-channel data.However,these heat transfer data of Koyama et al.at higher vapor qualities seem to be unrea-sonable since they should correspond to the dryout region and their trend contradicts in general with the other results. Another example of anomaly was found in the experimen-tal data of Yun et al.[21].According to their results,a heat transfer coe?cients up to80%higher was obtained with a very little change of hydraulic diameters from1.53mm to 1.54mm at equal test conditions.Those authors have not explained why there is such a big di?erence even at nearly

L.Cheng et al./International Journal of Heat and Mass Transfer49(2006)4082–40944085

the same test conditions.In all,the experimental data from di?erent studies show somehow di?erent heat transfer behaviors and thus will a?ect the accuracy of the new heat transfer model and the new?ow pattern map to be devel-oped for CO2in the present study since no conclusive rea-sons for the contradicting trends could be found and it is not possible to say which study is right either.

3.New CO2?ow pattern map

The new?ow pattern map for CO2is developed accord-ing to the corresponding heat transfer mechanisms in var-ious?ow regimes.Based on the heat transfer data in the database,the intermittent?ow to annular?ow(I–A)and the annular?ow to dryout region(A–D)transition criteria in the?ow pattern map of Wojtan et al.[29]have been modi?ed to?t the experimental data of CO2.The new?ow pattern map is intrinsically related to the corresponding heat transfer mechanisms of CO2.To re?ect the real mass ?ow velocities,equivalent diameters are used for non-circu-lar channels.Other transition criteria are the same as that of Wotjan et al.Thus,based on the fact that the original publications can be easily found,the other?ow patterns transition criteria by[29]will not be described here.

3.1.Modi?cations to the?ow pattern map for CO2

Flow patterns at diabatic conditions are intrinsically related to the corresponding?ow boiling heat transfer characteristics.The?ow patterns can be used to explain physically the heat transfer mechanisms and characteris-tics.Vice versa,the heat transfer mechanisms and charac-teristics can be used to backout the corresponding?ow patterns.CO2reveals strong nucleate boiling heat transfer characteristics in intermittent?ow at low vapor quality due to its physical properties.The distinction between intermit-tent?ow and annular?ow was indicated by the sharp fall-o?of heat transfer coe?cients between the two?ow regimes.The onset of dryout inception was also observed by a sharp drop in heat transfer.Therefore,the distinction between annular?ow and dryout region can be https://www.sodocs.net/doc/b84172836.html,bining with the heat transfer model for CO2 (in Section4),the I–A and A–D transition boundaries pro-posed by Wotjan et al.[29]were further modi?ed so as to ?t the heat transfer characteristics.Based on the experi-mental data,the following I–A and A–D transition criteria are proposed for CO2as

1.The I–A transition boundary is calculated with the new

criterion as follows:

x IA??1:81=0:875eq V=q LTà1=1:75el L=l VTà1=7t1 à1e2T2.The A–D transition boundary is calculated with the new

criterion as follows:

G dryout?

1

0:67

ln

0:58

x

t0:52

!D

q V r

à0:17

(

?

1

gD q Veq Làq VT

!à0:348q

V

q L

à0:25q

q

crit

à0:7)0:965

e3T

4086L.Cheng et al./International Journal of Heat and Mass Transfer49(2006)4082–4094

which is extracted from Eq.(15)(in Section4)for the dry-out inception of CO2.In this equation,q crit is calculated according to Kutateladze[36].For non-circular channels, equivalent diameters are used.

https://www.sodocs.net/doc/b84172836.html,parison of the new?ow pattern map for CO2to experimental data

Fig.3(a)shows the comparison of the new?ow pattern map for CO2and the?ow pattern map of Wojtan et al.to the experimental data of Yun et al.[21]at the indicated test conditions(in the?ow pattern map,A stands for annular ?ow,D stands for dryout region,I stands for intermittent ?ow,M stands for mist?ow,S stands for strati?ed?ow and SW stands for strati?ed-wavy?ow.The strati?ed to strati?ed-wavy?ow transition is designated as S–SW,the strati?ed-wavy to intermittent/annular?ow transition is designated as SW–I/A,the intermittent to annular?ow transition is designated as I–A and so on.).Arrow1shows the change of I–A transition boundaries and arrow2shows the change of A–D transition boundaries from the?ow pattern map of Wojtan et al.to the new?ow pattern map for CO2.Arrow3shows the changes of the S–SW/ Slug+SW transition boundaries that are automatically changed due to the change of I–A and A–D transition boundaries.Other transition boundaries are the same. Fig.3(b)shows the corresponding comparison of the pre-dicted heat transfer coe?cients with the heat transfer model of Wojtan et al.and the new heat transfer model for CO2(in Section4)to the experimental data at the same conditions as that in Fig.3(a).Obviously,the?ow pattern map of Wojtan et al.cannot re?ect the corresponding CO2heat transfer characteristics correctly and the heat transfer model of Wojtan et al.predicts poorly the experimental heat transfer coe?cients of CO2.The new CO2?ow pattern map re?ects the heat transfer mechanisms well in the corre-sponding?ow regimes and the CO2heat transfer model predicts the corresponding CO2experimental heat transfer coe?cients well.The heat transfer coe?cients start to fall in the A–D transition due to the inception of dryout at the top of the tube and then fall o?sharply in the dryout region.The predicted and the experimental heat transfer coe?cients are in good agreement in these?ow regimes. It should be mentioned here that there are only two studies of?ow visualization of CO2?ow boiling[23,24]in the lit-erature.Unfortunately,neither contains the corresponding study of heat transfer characteristics which should be related to the observed?ow patterns.In addition,in the study of Yun et al.[23],the maximum mass velocity reaches1500kg/m2s,which is much higher than the max-imum value570kg/m2s in the present database and their heat?ux is100kW/m2,which is also much higher than the maximum heat?ux32kW/m2in the present database. In the study of Pettersen[24],it is di?cult to interpret some of his observations by his de?nitions of the?ow regimes in our?ow pattern map.It is also di?cult to judge some of his?ow regimes so as to compare to the new?ow pattern map.

4.New?ow boiling heat transfer model for CO2

It is a formidable task to develop a general?ow boiling heat transfer model for CO2because of the diversities of the heat transfer trends in the database.To develop a gen-eral prediction method,it is important that the method is

L.Cheng et al./International Journal of Heat and Mass Transfer49(2006)4082–40944087

not only numerically accurate but that it captures correctly the trends in the data.Most importantly,the heat transfer mechanisms should be related to the corresponding ?ow patterns and be physically explained according to ?ow pat-tern transitions.Accordingly,a new general heat transfer model is proposed here using the Wojtan et al.[30]model as our starting point.Equivalent diameters are used for non-circular channels.

4.1.Brief description of the ?ow boiling heat transfer model of Wojtan et al.

Wojtan et al.[30]extended the Kattan–Thome–Favrat [31–33]heat transfer model to include dryout region and mist ?ow heat transfer methods and improved the heat transfer prediction in strati?ed-wavy ?ows.The Kattan–Thome–Favrat general equation for the local heat transfer coe?cients h tp in a horizontal tube is

h tp ?h dry h V t2p àh dry àáh wet ??

2p

e4Twhere h dry is the dry angle as shown in Fig.4.The dry angle

de?nes the ?ow structures and the ratio of the tube perim-eters in contact with liquid and vapor.In strati?ed ?ow,h dry equals the strati?ed angle,h strat ,which is calculated according to Thome and El Hajal [37].In annular and intermittent ?ows,h dry =0.For strati?ed-wavy ?ow,h dry varies from zero up to its maximum value h strat .Wojtan et al.subdivided the strati?ed-wavy ?ow into three sub-zones (slug,slug/strati?ed-wavy and strati?ed-wavy).Based on the fact that the high frequency slugs maintain a continuous thin liquid layer on the upper tube perimeter,h dry is de?ned equal to 0in the slug zone.The dry angles in the slug/strati?ed-wavy and strati?ed-wavy regions are cal-culated according to equations developed by Wojtan et al.[30]based in exponential interpolations giving smooth transition in the determination of dry angle between respective zones and also a smooth transition in the heat transfer coe?cient from zone to zone.

The vapor phase heat transfer coe?cient on the dry perimeter h V is calculated with the Dittus–Boelter [38]cor-relation assuming tubular ?ow in the tube:

h V ?0:023Re 0:8V Pr 0:4

V ek V =D T

e5T

and the heat transfer coe?cient on the wet perimeter is cal-culated with an asymptotic model that combines the nucle-

ate boiling and convective boiling contributions to the heat

transfer by the third power:h wet ??eh nb T3

th 3cb

1=3

e6T

In this equation,the correlation proposed by Cooper [39]multiplied by a ?xed boiling suppression factor of 0.8is used to calculate the nucleate boiling contribution.The convective contribution is calculated with the following correlation assuming a liquid ?lm ?ow:

h cb ?0:01334G e1àx Td l L e1àe T 0:69Pr 0:4L

k L

d e7Twher

e the term in the bracket is the liquid ?lm Reynolds

number.In this equation,the void fraction is determined with the Rouhani and Axelsson [40]drift ?ux model (as in [29–33])and the liquid ?lm thickness is calculated as suggested by El Hajal et al.[41].

The heat transfer coe?cient in mist ?ow is calculated as follows [30]:

h mist ?0:0117Re 0:79H Pr 1:06V Y

à1:83

ek V =D Te8T

where Re H is the homogeneous Reynolds number and Y is the correction factor originally proposed by Groeneveld [42]and given by

Y ?1à0:1?eq L =q V à1Te1àx T

0:4

e9T

The heat transfer coe?cient in the dryout region is calculated by proration as [30]h dryout ?h tp ex di Tà

x àx di

x de àx di

?h tp ex di Tàh mist ex de T

e10T

where h tp (x di )is the two-phase ?ow heat transfer coe?cient calculated from Eq.(4)at the dryout inception quality x di and h mist (x de )is the mist ?ow heat transfer coe?cient calcu-lated from Eq.(8)at the dryout completion quality x de .If x de is not de?ned at the considered mass velocity it is assumed that x de =0.999.For more details about the ?ow boiling heat transfer model and ?ow patterns map pro-posed by Wotjan et al.[29,30],we suggest to consult the original papers.

4.2.Modi?cations in the new ?ow boiling heat transfer model for CO 2

Like any other ?ow boiling heat transfer model,both the Kattan–Thome–Favrat model and the modi?ed model of Wojtan et al.drastically underpredicts the heat transfer coe?cients for CO 2,particularly at low and intermediate vapor qualities as shown in Fig.3(b).Moreover,CO 2at high saturation pressures gives a trend of a monotonic decrease in heat transfer coe?cient versus vapor quality in intermittent and annular ?ows,which is the exact oppo-site of the trend for other refrigerants such as R-134a at low pressures [8,9].The nucleate boiling contribution is much larger than the convective boiling contribution for CO 2while the opposite is true for R-134a.

Hence,

Fig.4.Schematic diagram of annular ?ow with partial dryout.

4088L.Cheng et al./International Journal of Heat and Mass Transfer 49(2006)4082–4094

suppression of nucleate boiling acts on the heat transfer coe?cients of CO2to greatly reduce its contribution to the heat transfer with the increase of vapor quality.There-fore,to develop a general model for CO2,?rst,a new nucle-ate boiling heat transfer correlation is needed especially for CO2.Then,a reasonable suppression factor is needed so as to capture the correct parametric trend of CO2.Further-more,a correlation of dryout inception is needed so as to predict accurately the heat transfer in dryout region by considering the fact that the dryout phenomenon of CO2 occurs much earlier than that of other refrigerants.All these aspects should be based on physically reasonable grounds as the heat transfer mechanisms are intrinsically related to the corresponding?ow patterns.

4.2.1.Development of a new nucleate boiling heat transfer correlation for CO2

The experimental heat transfer data at vapor qualities x In order to develop the new nucleate boiling correlation for CO2,reduced pressure is one key factor veri?ed by the previous experimental studies.So the reduced pressure based Cooper correlation is used to modify the nucleate boiling heat transfer for CO2.By analyzing and comparing the nucleate boiling heat transfer data,it was found that the heat?ux term in the Cooper correlation did not re?ect the real trend for CO2nucleate boiling heat transfer. Thus,the exponent of the heat?ux was newly determined based on the nucleate boiling data of CO2,and a value of 0.58compared to the original value of0.67.Then,the reduced pressure term was correlated based on the nucleate boiling heat transfer data of CO2by keeping the logarith-mic and molecular terms in the Cooper correlation unchanged.The following new nucleate boiling heat trans-fer correlation was obtained: h nb?131pà0:0063 r eàlog10p rTà0:55Mà0:5q0:58e11TFig.5shows the comparison of the predicted nucleate boiling heat transfer coe?cients by the new nucleate boil-ing heat transfer correlation for CO2with the present data-base.About90%of the experimental nucleate boiling heat transfer coe?cients are predicted within±20%. 4.2.2.Development of a nucleate boiling heat transfer suppression factor correlation for CO2 As nucleate boiling heat transfer is suppressed in annu-lar?ow,a boiling suppression factor correlation is needed in the?ow boiling heat transfer model for CO2so as to capture the trend of heat transfer characteristics.To develop the boiling suppression factor correlation for CO2,?rst the physical mechanisms of?ow boiling heat transfer are considered and secondly the e?ect of tube diameters.Unlike other boiling suppression factor correla-tions such as in Chen[44]and Gungor and Winterton[45] correlations,which were empirically correlated based on the Lockhart–Martinelli number,Reynolds number,Boil-ing number,Prandtl number and so on,liquid?lm thick-ness is used as a main parameter in the present study. The Cooper correlation was?rst replaced with the new nucleate boiling heat transfer correlation.Then,the boiling L.Cheng et al./International Journal of Heat and Mass Transfer49(2006)4082–40944089 suppression factors were backed out of the whole database (except the dryout data points).Incorporating the e?ect of tube diameter,the following boiling suppression factor correlation was obtained for CO2: If x where D ref=0.00753m. Furthermore,if D>7.53mm,then set D=7.53mm. For non-circular channels,the equivalent diameter is used. The correlation is applicable to the conditions:à28°C6 T sat625°C,5kW/m26q632kW/m2,170kg/m2s6 G6570kg/m2s,0.8mm6D610mm. Combining the nucleate boiling heat transfer correlation for CO2and the nucleate boiling heat transfer suppression factor correlation,the?ow boiling heat transfer coe?cients on the wet perimeter are calculated according to the following: h wet??eSáh nbT3th3 cb 1=3e14T 4.2.3.New dryout region heat transfer correlation for CO2 Some of the?ow boiling heat transfer data of CO2in the database contain obviously the dryout points as the heat transfer coe?cients fall o?sharply.In the process of devel-oping the boiling suppression factor correlation,the dryout data were determined according to the corresponding boil-ing suppression factors.Those giving negative boiling sup-pression factor values were taken as the dryout points and the data giving boiling suppression factor values around zero were taken as indicating the onset of the dryout.Based on the dryout inception data,the dryout inception vapor quality correlation of Wojtan et al.was modi?ed and thus a new annular to dryout region(A–D)transition boundary in the?ow pattern map was extracted from the modi?ed dryout inception vapor quality correlation Eq.(15)for CO2.By comparing the new?ow pattern map with the experimental data,the dryout inception vapor quality cor-relation was further modi?ed according to the heat transfer characteristics and mechanisms together with the corre-sponding?ow regimes.The new dryout inception vapor quality correlation is x di?0:58exp0:52à0:67We0:17 V Fr0:348 V eq V=q LT0:25eq=q critT0:7 h i e15TBased on the new dryout inception vapor quality corre-lation,the new A–D transition criterion(Eq.(3))for CO2 was obtained as pointed out in Section3.1.The dryout inception vapor qualities are calculated with Eq.(15)and thus the heat transfer coe?cients in the dryout region are calculated with Eq.(10).The dryout completion vapor quality is x de=0.999as suggested by Wojtan et al.[30] due to the lack of the experimental data for CO2. 4090L.Cheng et al./International Journal of Heat and Mass Transfer49(2006)4082–4094 https://www.sodocs.net/doc/b84172836.html,parisons of the new?ow boiling heat transfer model to the database As indicated in the forgoing,the general?ow boiling heat transfer model is proposed for CO2which incorpo-rates the new nucleate boiling heat transfer correlation, the new boiling suppression factor correlation and the new modi?ed dryout region heat transfer correlation.In order to verify the new?ow boiling heat transfer model, the whole experimental database were used to evaluate the new heat transfer model.Figs.6–10show the compar-isons of the predicted with the experimental heat transfer coe?cients at the indicated test conditions.Generally,the new heat transfer model predicts the experimental heat transfer coe?cients and captures the trends of the experi-mental heat transfer coe?cients except for those of Koy-ama et al.at high vapor qualities,as shown in Fig.9, and the entire data of Knudesen and Jensen et al.as shown in Fig.10(b).As already shown in Fig.2(b),the experimen-tal data of Koyama et al.reveal an opposite trend com-pared to most of the other data.According to the new ?ow pattern map for CO2,these data at high vapor quality should be in the dryout region and the heat transfer coe?-cients should show a decrease with the increasing vapor quality while instead they show an increase.The new heat transfer model poorly predicts the data of Knudsen as shown in Fig.10(b).Apparently,the?ow pattern of their data is in the strati?ed wavy?ow region as shown in the corresponding?ow pattern map in Fig.10(a).This is con-?rmed by the measured temperatures in the top,middle and bottom positions as shown in their paper.The temper-atures at the top are higher than that at the bottom,which means that the top of the tube was in contact with vapor and the bottom of the tube was in contact with liquid.In order to?nd the reason why the predicted heat transfer coe?cients are much lower than the experimental data, the new?ow heat transfer model was arti?cially changed to predict the heat transfer coe?cients in the annular?ow region for the same test conditions as shown by the dashed line in Fig.10(b).The predicted heat transfer coe?cients are still lower than the experimental heat transfer coe?-cients even assuming the?ow is annular.Fortunately,some of the data of Yun and Kim[9]at a mass velocity of 170kg/m2s are in or near the strati?ed-wavy region as shown in Fig.11(a)and thus can be used to evaluate the new heat transfer model in the strati?ed-wavy?ow region L.Cheng et al./International Journal of Heat and Mass Transfer49(2006)4082–40944091 as well.Fig.11(b)shows the comparison of the predicted heat transfer coe?cients with the experimental data of Yun and Kim[9]at the indicated test conditions.The experimental heat transfer coe?cients of Yun and Kim in the strati?ed-wavy?ow region are well predicted by the new model.To further?nd the reason why the new heat transfer model under predict the experimental heat transfer coe?cients of Knudesen and Jensen et al.,the experimental and data reduction methods in their study have been ana-lyzed.The test section is a stainless tube with a length of 1.12m,an inside diameter of10.06mm and an outside diameter of30mm.The test tube was heated by condens-ing R22vapor on the outside of the tube.However,how the total heat transferred to the test section was determined is not mentioned in their paper.The total heat transferred to the test section could be a key factor that caused the big discrepancy here.In addition,heating by condensation gives a constant temperature boundary rather than a uni-form heat?ux boundary.So,it seems that using the aver-age temperature of the12measured temperatures at three di?erent positions together with the total heat?ux to calcu-late the inside wall temperature may be unreasonable. Therefore,their data are excluded in the following statisti-cal analysis. Fig.12shows the comparison of the predicted and experimental heat transfer coe?cients for the whole exper-imental database.The statistical analysis of the predicted results are listed in Table2.75.5%of the whole experimen-tal database are predicted within±30%and79.1%of the experimental data without dryout points are predicted ±30%.As for such a wide range of experimental data from di?erent laboratories,especially some of the experimental data showing opposite heat transfer behaviors,the pre-dicted results are quite reasonable and encouraging.Due to the lack of the dryout completion data,the prediction for the dryout region heat transfer is worse than that for the other?ow regimes.It could be improved in the future if some of the experimental dryout completion data become available. 5.Conclusions A new?ow boiling heat transfer model and a new?ow pattern map for two-phase?ow in horizontal tubes have Table2 Statistical analysis of the predicted results Data used for comparison Data points Percentage of predicted points within±30% Mean deviation, j e j(%) Standard deviation, r(%) All data points31875.527.147.2 Data without dryout points 28779.123.547.5 4092L.Cheng et al./International Journal of Heat and Mass Transfer49(2006)4082–4094 been developed speci?cally for CO2.The new?ow pattern map and the new heat transfer model are intrinsically related each https://www.sodocs.net/doc/b84172836.html,pared to the CO2heat transfer model of Thome and El Hajal,several key aspects have been improved.First,a nucleate boiling heat transfer cor-relation is proposed for CO2according to the e?ect of heat ?ux and reduced pressure on nucleate boiling heat transfer at low vapor qualities.Secondly,a nucleate boiling sup-pression factor correlation is proposed based on the liquid ?lm thickness and the e?ect of tube diameter on heat trans-fer.In addition,a dryout inception vapor quality correla-tion is proposed for CO2and accordingly the heat transfer correlation in the dryout region is obtained.Based on the heat transfer mechanisms,a new?ow patterns map is proposed and thus can physically explain the heat trans-fer phenomena according to the?ow regimes de?ned by the new?ow map.The new heat transfer model predicts75.5% of the CO2database(318data points)to within±30%and 79.1%of the CO2database(287)without dryout data points.The heat transfer model and the corresponding?ow pattern map are applicable to a wide range of conditions: tube diameters(equivalent diameter for non-circular channels)from0.8to10mm,mass velocities from85to 570kg/m2s,heat?uxes from5to32kW/m2and satura-tion temperatures fromà25to+25°C. Acknowledgements Dr.Lixin Cheng is an Alexander von Humboldt Re-search Fellow in the Institute of Process Engineering at the University of Hannover in Germany and was a visiting Research Fellow in the Laboratory of Heat and Mass Transfer at Swiss Federal Institute of Technology(Lau-sanne)in Switzerland from January to March2005.The visit was sponsored by a European Research Fellowship of the Alexander von Humboldt Foundation and the re-search is supported by the Alexander von Humboldt Foun-dation.Dr.Leszek Wojtan is supported by the Swiss FN contract number510.597. References [1]L.Lorentzen,Revival of carbon dioxide as refrigerant,Int.J. Refrigeration17(1994)292–301. [2]P.Neksa,H.Reksta,G.R.Zakeri,P.A.Schie?oe,CO2heat pump water heater characteristics,system design and experimental results, Int.J.Refrigeration21(1998)172–179. [3]K.Klo¨cker,E.L.Schmidt,F.Steimle,Carbon dioxide as a working ?uid in drying heat pumps,Int.J.Refrigeration24(2001)100–107. [4]P.Neksa,CO2heat pump systems,Int.J.Refrigeration25(2002) 421–427. [5]J.R.Thome,G.Ribatski,State-of-the art of?ow boiling and two- phase?ow of CO2in macro-and micro-channels,Int.J.Refrigeration 28(2006)1149–1168. [6]A.Bredesen,A.Hafner,J.Pettersen,P.Neksa,K.A?ekt,Heat transfer and pressure drop for in-tube evaporation of CO2, in:Proceedings of the International Conference in Heat Transfer Issues in Natural Refrigerants,University of Maryland,USA,1997, pp.1–15. [7]H.J.Knudsen,R.H.Jensen,Heat transfer coe?cient for boiling carbon dioxide,in:Workshop Proceedings–CO2Technologies in Refrigeration,Heat Pumps and Air Conditioning Systems,Trond-heim,Norway,1997,pp.319–328. [8]R.Yun,J.H.Hwang,Y.C.Kim,M.S.Kim,Evaporation heat transfer characteristics of carbon dioxide in a horizontal smooth tube, IIR Commission B1Meeting,Paderborn,Germany,2001,pp.519–525. [9]R.Yun,Y.Kim,M.S.Kim,Y.Choi,Boiling heat transfer and dryout phenomenon of CO2in a horizontal smooth tube,Int.J.Heat Mass Transfer46(2003)2353–2361. [10]S.Jeong,D.Jeong,J.J.Lee,Evaporating heat transfer and pressure drop inside helical coils with the refrigerant carbon dioxide,in:21st IIR International Congress of Refrigeration,Washington DC,USA, 2003,paper ICR0260. [11]N.N.Sawant,M.S.Kim,W.Vance Payne,P.A.Domanski,Y.W. Hwang,A study of in-tube evaporation heat transfer of carbon dioxide,in:21st IIR International Congress of Refrigeration, Washington DC,USA,2003,paper ICR0038. [12]J.Wang,S.Ogasawara,E.Hihara,Boiling heat transfer and air coil evaporator of carbon dioxide,in:21st IIR International Congress of Refrigeration,Washington DC,USA,2003,paper ICR0231. [13]S.H.Yoon,E.S.Cho,M.S.Kim,Y.Kim,Studies on the evaporative heat transfer and pressure drop of carbon dioxide near the critical point,in:21st IIR International Congress of Refrigeration,Wash-ington DC,USA,2003,paper ICR0477. [14]S.H.Yoon,E.S.Cho,Y.W.Hwang,M.S.Kim,K.Min,Y.Kim, Characteristics of evaporative heat transfer and pressure drop of carbon dioxide and correlation development,Int.J.Refrigeration27 (2004)111–119. [15]S.Koyama,S.Lee,D.Ito,K.Kuwahara,H.Ogawa,Experimental study on?ow boiling of pure CO2and CO2–oil mixtures inside horizontal smooth and micro-?n copper tubes,in:Proceedings of6th IIR-Gustav Lorentzen Conference,Glasgow,UK,2004,paper1/A/ 1.40. [16]S.Koyama,K.Kuwahara, E.Shinmura,S.Ikeda,Experimental study on?ow boiling of carbon dioxide in a horizontal small diameter tube,in:IIR Commission B1Meeting,Paderborn,Germany,2001, pp.526–533. [17]X.Huai,S.Koyama,T.S.Zhao,E.Shinmura,K.Hidehiko,M. Masaki,An experimental study of?ow boiling characteristics of carbon dioxide in multiport mini channels,Appl.Thermal Eng.24 (2004)1443–1463. [18]H.Ohta,Boiling two-phase?ow in channels with extremely small dimensions–review of Japanese research,in:2nd International Conference on Microchannels and Minichannels,Rochester,USA, 2004,pp.97–108. [19]V.Siegismund,M.Kau?eld,In?uence of lubricant oil on CO2heat transfer in minichannel tubes,in:Proceedings of6th IIR-Gustav Lorentzen Conference,Glasgow,UK,2004,paper1/B/2.20. [20]J.Pettersen,Flow vaporization of CO2in microchannel tubes,Exp. Thermal Fluid Sci.28(2004)111–121. [21]R.Yun,Y.Kim,M.S.Kim,Convective boiling heat transfer characteristics of CO2in microchannels,Int.J.Heat Mass Transfer 48(2005)235–242. [22]R.Yun,Y.Kim,M.S.Kim,Two-phase?ow patterns of CO2in a narrow rectangular channel,in:21st IIR International Congress of Refrigeration,Washington DC,USA,2003,paper ICR0155. [23]R.Yun,Y.Kim,Flow regimes for horizontal two-phase?ow of CO2 in a heated narrow rectangular channel,Int.J.Multiphase Flow30 (2004)1259–1270. [24]J.Pettersen,Two-phase?ow patterns in microchannel vaporization of CO2at near-critical pressure,Heat Transfer Eng.25(2004)52–60. [25]R.Yun,Y.Kim,Critical quality prediction for saturated?ow boiling of CO2in horizontal small diameter tubes,Int.J.Heat Mass Transfer 46(2003)2527–2535. [26]J.R.Thome,J.El Hajal,Flow boiling heat transfer to carbon dioxide: general prediction method,Int.J.Refrigeration27(2004)294–301. L.Cheng et al./International Journal of Heat and Mass Transfer49(2006)4082–40944093 [27]S.G.Kandlikar,Fundamental issues related to?ow boiling in minichannels and microchannels,Exp.Thermal Fluid Sci.26(2002) 38–47. [28]P.A.Kew,K.Cornwell,Correlations for the prediction of boiling heat transfer in small-diameter channels,Appl.Thermal Eng.17 (1997)705–715. [29]L.Wojtan,T.Ursenbacher,J.R.Thome,Investigation of?ow boiling in horizontal tubes:part I–a new diabatic two-phase?ow pattern map,Int.J.Heat Mass Transfer(2005)2955–2969. [30]L.Wojtan,T.Ursenbacker,J.R.Thome,Investigation of?ow boiling in horizontal tubes:part II–development of a new heat transfer model for strati?ed-wavy,dryout and mist?ow regimes,Int.J.Heat Mass Transfer(2005)2970–2985. [31]N.Kattan,J.R.Thome, D.Favrat,Flow boiling in horizontal tubes.Part1:Development of a diabatic two-phase?ow pattern map, J.Heat Transfer120(1998)140–147. [32]N.Kattan,J.R.Thome,D.Favrat,Flow boiling in horizontal tubes: part2–new heat transfer data for?ve refrigerants,J.Heat Transfer 120(1998)148–155. [33]N.Kattan,J.R.Thome,D.Favrat,Flow boiling in horizontal tubes: part–3:development of a new heat transfer model based on?ow patterns,J.Heat Transfer120(1998)156–165. [34]Y.Hwang, B.H.Kim,R.Radermacher,Boiling heat transfer correlation for carbon dioxide,in:Proceedings of International Conference on Heat Transfer Issues in Natural Refrigerants, November,University of Maryland,USA,1997,pp.81–94. [35]REFPROP.NIST Refrigerant Properties Database23,Gaithersburg, MD,1998,version6.01.[36]S.S.Kutateladze,On the transition to?lm boiling under natural convection,Kotloturbostroenie(3)(1948)10–12. [37]J.R.Thome,J.El Hajal,Two-phase?ow pattern map for evaporation in horizontal tubes:Latest version,in:1st International Conference on Heat Transfer,Fluid Mechanics and Thermodynamics,Kruger Park,South Africa,vol.1,April8–10,2002,pp.182–188. [38]F.W.Dittus,L.M.K.Boelter,Heat transfer in automobile radiator of the tubular type,Univ.Calif.Publ.Eng.2(13)(1930)443–461. [39]M.G.Cooper,Heat?ow rates in saturated nucleate pool boiling–a wide-ranging examination of reduced properties,Advances in Heat Transfer16(1984)157–239. [40]Z.Rouhani,E.Axelsson,Calculation of volume void fraction in a subcooled and quality region,Int.J.Heat Mass Transfer17(1970) 383–393. [41]J.El Hajal,J.R.Thome,A.Cavallini,Condensation in horizontal tubes:part2–new heat transfer model based on?ow regimes,Int.J. Heat Mass Transfer46(18)(2003)3365–3387. [42]D.C.Groeneveld,Post dry-out heat transfer at reactor operating conditions,in:ANS Topical Meeting on Water Reactor Safety,Salt Lake City,1973. [43]D.Goren?o,Pool boiling(Chapter Ha)VDI Heat Atlas,VDI-Verlag, Du¨sseldorf,1993. [44]J.C.Chen,Correlation for boiling heat-transfer to saturated?uids in convective?ow,Ind.Chem.Eng.Proc.Des.Dev.5(1966)322–339. [45]K.E.Gungor,R.H.S.Winterton,A general correlation for?ow boiling in tubes and annuli,Int.J.Heat Mass Transfer29(1986)351–358. 4094L.Cheng et al./International Journal of Heat and Mass Transfer49(2006)4082–4094 巴尔扎克简介(1799~1850) 法国小说家.1799年5月20日生于巴黎以南的图尔城, 1850年8月18日卒于巴黎.巴尔扎克的一生,处于19世纪前半期的50年,经历了拿破仑帝国的战火纷飞的岁月,动荡不安的封建复辟王朝,以及以阴谋复辟帝制的路易□波拿巴为总统的第二共和国.他用总标题为《人间喜剧》的一系列小说,反映了剧烈的社会变革时期的法国生活. 巴尔扎克出生后不久就被送到附近的乡村去寄养. 上小学后一直到中学毕业,他始终寄住在宿舍里,没有能回 家过一段比较长的日子,享受家庭生活的温暖.离开家庭的童年生活的痛苦使他毕生难忘. 巴尔扎克的父亲原姓巴尔沙,是个精明强干的人. 他来自农村,幼年时跟当地教士学了一点文化,中年致富,在外省当过副市长,供应军粮的承包商,在巴黎经营过呢绒商业,当过巴黎驻军的军需负责人,是一个白手起家的资产者. 1816年,17岁的巴尔扎克结束中学的学业后进大学法科,并在文科旁听.18岁时,先后在诉讼代理人和公证人的办事处当见习生或书记. 从20岁开始,巴尔扎克决定从事文学创作.他在巴黎贫民区租了一间房顶上的阁楼,由父母供给极有限的一点生活费,埋头写作.他的第一部作品是五幕诗体悲剧《克伦威尔》,这是一部完全失败的作品,没有引起任何人的兴趣.接连又写了十多部小说,有的是自己所写,有的是和别人合写.这一阶段他所写的小说全用笔名发表.这些作品并没有给他带来生活所需要的物质条件,他只好暂时放弃文学.1826年借钱出版了一部普及版的《莫里哀全集》,接着又出版一部拉封丹寓言诗集, 销路不佳,亏损负债9,000法郎.后又借债经营印刷厂和铸字厂,均以赔本告终.他前后负债共达6万多法郎. 从1828年夏季开始,巴尔扎克决定重新回到文学事业上来.他写了一部以布列塔尼封建势力武装叛乱反对共和国为题材的小说《最后一个舒昂党人》(后来编入《人间喜剧》,改名《舒昂党的人们》).这是巴尔扎克所写的第一部严肃的文学作品,第一次用巴尔扎克真姓名发表.此书问世,初步奠定了作者在文学界的地位. 接着发表小说《婚姻生理学》,在读者之间引起广泛注意.1831年他的新著《驴皮记》出版,巴尔扎克立即成为法国最负盛名的作家之一. 1819到1829年,是巴尔扎克在文学事业上的探索阶段.从1829年开始,一直到1848年,是他创作《人间喜剧》的时期,也是他文学事业的全盛时期.他用超人的才智与精力,在不到20年的时间内,共创作小说91部.平均每年产生作品四,五部之多.他每日伏案一般都在10小时以上,常常连续工作18小时.有时文思如泉涌,或者为了赶写稿子,他一连几天废寝忘餐,夜以继日地劳动.根据阿尔贝·贝干教授提供的材料,巴尔扎克的杰作《高老头》(原名《高立欧老爹》)是他用三天三夜一气呵成的. 什么是《人间喜剧》的作者的创作动力人们说是因为他负债过多,需要用稿费还债.巴尔扎克年轻时经营印刷出版业确曾负债巨万.但从他成为名重一时的小说家之后,他的收入丰厚,出版商争着和他签订合同,不惜重金预约他尚未完成或尚未动笔的小说稿,早年的债务早已还清.名作家巴尔扎克生活阔绰,醉心于豪华的排场.他在巴黎同时安置了几处住宅和别墅,出门坐最富丽的马车,驾着骏马;仆役都穿制服;他也服饰华贵, 出入于名门大户的沙龙.由此可见,他的勤奋创作,绝对不是由于贫困. 巴尔扎克从年轻时开始就自信有很高的文学才能, 对文学有极大的抱负.他不舍昼夜地勤奋写作,主要因为有一股激情在内心沸腾,促使他充分发挥自己的才能, 要求在文艺界做一番伟大的事业.在他的书室里,有一座作为摆饰的小型拿破仑塑像.在塑像座盘边上,巴尔扎克亲笔写着:"他用宝剑未能完成的大业,我将用笔杆来完成." 巴尔扎克要完成的伟大事业就是《人间喜剧》这座巍峨的文学里程碑.第一次在这位小说家笔下出现《人间喜剧》这个名词是在1813年.毫无疑问,《人间喜剧》的命名是受但丁长诗《神圣喜剧》(中译《神曲》)标题的启发.1841年,巴尔扎克确定了这个庞大的创作计划.当时有四家出版商和巴尔扎克签订合同,合资承包《人间喜剧》的出版工作.1842年,巴尔扎克写了《人间喜剧·导言》,阐述他写作这部史无前例的文学巨著的宗旨.1845年巴尔扎克亲笔写的《人间喜剧总目》,一直保存到现在.根据这个《总目》,《人间喜剧》分为三大部分:《风俗研究》,《哲理研究》和《分析研究》. 《风俗研究》内容最为丰富,包括小说最多.因此这一部分又分为六个门类:1.《私人生活场景》,2.《外省生活场景》,3.《巴黎生活场景》,4.《政治生活场景》, 5.《军队生活场景》,6.《乡村生活场景》.《私人生活场景》包括32部小说,其中4部当时已有提纲,尚未起稿.已经完成的28部之中包括著名的《高老头》(1834), 《猫滚球布店》(1830),《夏倍上校》(1832)和《三十岁的女人》(1831~1834)等.《外省生活场景》包括17 部小说,其中6部尚未完成;已经发表的11部中包括《欧也妮·葛朗台》(1833),《幽谷百合》(1835)和《幻灭》(1837~1843)等.《巴黎生活场景》共有20部小说, 其中6部尚未产生;在已经发表的小说中有《金目少女》 (1834),《纽沁根银行》(1838),《塞沙·皮罗多兴衰记》(1837), 巴尔扎克简介 巴尔扎克(Honore de Balzac,1799~1850),他是19世纪法国伟大的批判现实主义作家,欧洲批判现实主义文学的奠基人和杰出代表。一生创作96部长、中、短篇小说和随笔,总名为《人间喜剧》。其中代表作为《欧也妮·葛朗台》、《高老头》。100多年来,他的作品传遍了全世界,对世界文学的发展和人类进步产生了巨大的影响。马克思、恩格斯称赞他“是超群的小说家”、“现实主义大师”。 巴尔扎克出生于一个法国大革命后致富的资产阶级家庭,法科学校毕业后,拒绝家庭为他选择的受人尊敬的法律职业,而立志当文学家。为了获得独立生活和从事创作的物质保障,他曾试笔并插足商业,从事出版印刷业,但都以破产告终。这一切都为他认识社会、描写社会提供了极为珍贵的第一手材料。他不断追求和探索,对哲学、经济学、历史、自然科学、神学等领域进行了深入研究,积累了极为广博的知识。 1829年,巴尔扎克完成长篇小说《朱安党人》,这部取材于现实生活的作品为他带来巨大声誉,也为法国批判现实主义文学放下第一块基石,巴尔扎克将《朱安党人》和计划要写的一百四五十部小说总命名为《人间喜剧》,并为之写了《前言》,阐述了他的现实主义创作方法和基本原则,从理论上为法国批判现实主义文学奠定了基础。 巴尔扎克在艺术上取得巨大成就,他在小说结构方面匠心独运,小说结构多种多样,不拘一格、并善于将集中概括与精确描摹相结合,以外形反映内心本质等手法来塑造人物,他还善于以精细人微、生动逼真的环境描写再现时代风貌。恩格斯称赞巴尔扎克的《人间喜剧》写出了贵族阶级的没落衰败和资产阶级的上升发展,提供了社会各个领域无比丰富的生动细节和形象化的历史材料,“甚至在经济的细节方面(如革命以后动产和不动产的重新分配),我学到的东西也要比从当时所有职业历史学家、经济学院和统计学家那里学到的全部东西还要多”。(恩格斯:《恩格斯致玛·哈克奈斯》) 巴尔扎克以自己的创作在世界文学史上树立起不朽的丰碑。 有限元网格划分的基本原则 划分网格是建立有限元模型的一个重要环节,它要求考虑的问题较多,需要的工作量较大,所划分的网格形式对计算精度和计算规模将产生直接影响。为建立正确、合理的有限元模型,这里介绍划分网格时应考虑的一些基本原则。 1网格数量 网格数量的多少将影响计算结果的精度和计算规模的大小。一般来讲,网格数量增加,计算精度会有所提高,但同时计算规模也会增加,所以在确定网格数量时应权衡两个因数综合考虑。 图1中的曲线1表示结构中的位移随网格数量收敛的一般曲线,曲线2代表计算时间随网格数量的变化。可以看出,网格较少时增加网格数量可以使计算精度明显提高,而计算时间不会有大的增加。当网格数量增加到一定程度后,再继续增加网格时精度提高甚微,而计算时间却有大幅度增加。所以应注意增加网格的经济性。实际应用时可以比较两种网格划分的计算结果,如果两次计算结果相差较大,可以继续增加网格,相反则停止计算。 图1位移精度和计算时间随网格数量的变化 在决定网格数量时应考虑分析数据的类型。在静力分析时,如果仅仅是计算结构的变形,网格数量可以少一些。如果需要计算应力,则在精度要求相同的情况下应取相对较多的网格。同样在响应计算中,计算应力响应所取的网格数应比计算位移响应多。在计算结构固有动力特性时,若仅仅是计算少数低阶模态,可以选择较少的网格,如果计算的模态阶次较高,则应选择较多的网格。在热分析中,结构内部的温度梯度不大,不需要大量的内部单元,这时可划分较少的网格。 2网格疏密 网格疏密是指在结构不同部位采用大小不同的网格,这是为了适应计算数据的分布特点。在计算数据变化梯度较大的部位(如应力集中处),为了较好地反映数据变化规律,需要采用比较密集的网格。而在计算数据变化梯度较小的部位,为减小模型规模,则应划分相对稀疏的网格。这样,整个结构便表现出疏密不同的网格划分形式。 图2是中心带圆孔方板的四分之一模型,其网格反映了疏密不同的划分原则。小圆孔附近存在应力集中,采用了比较密的网格。板的四周应力梯度较小,网格分得较稀。其中图b中网格疏密相差更大,它比图a中的网格少48个,但计算出的孔缘最大应力相差1%,而计算时间却减小了36%。由此可见,采用疏密不同的网格划分,既可以保持相当的计算精度,又可使网格数量减小。因此,网格数量应增加到结构的关键部位,在次要部位增加网格是不必要的,也是不经济的。 文章编号:1003-0794(2005)01-0038-02 基于ANSYS的有限元法网格划分浅析 杨小兰,刘极峰,陈 旋 (南京工程学院,南京210013) 摘要:为提高有限元数值的计算精度和对复杂结构力学分析的准确性,针对不同分析类型采用了不同的网格划分方法,结合实例阐述了ANSYS有限元网格划分的方法和技巧,指出了采用ANSYS有限元软件在网格划分时应注意的技术问题。 关键词:ANSYS;有限元;网格;计算精度 中图号:O241 82;TP391 7文献标识码:A 1 引言 ANSYS有限元分析程序是著名的C AE供应商美国ANSYS公司的产品,主要用于结构、热、流体和电磁四大物理场独立或耦合分析的CAE应用,功能强大,应用广泛,是一个便于学习和使用的优秀有限元分析程序。在ANSYS得到广泛应用的同时,许多技术人员对ANSYS程序的了解和认识还不够系统全面,在工作和研究中存在许多隐患和障碍,尤为突出的是有限元网格划分技术。本文结合工程实例,就如何合理地进行网格划分作一浅析。 2 网格划分对有限元法求解的影响 有限元法的基本思想是把复杂的形体拆分为若干个形状简单的单元,利用单元节点变量对单元内部变量进行插值来实现对总体结构的分析,将连续体进行离散化即称网格划分,离散而成的有限元集合将替代原来的弹性连续体,所有的计算分析都将在这个模型上进行。因此,网格划分将关系到有限元分析的规模、速度和精度以及计算的成败。实验表明:随着网格数量的增加,计算精确度逐渐提高,计算时间增加不多;但当网格数量增加到一定程度后,再继续增加网格数量,计算精确度提高甚微,而计算时间却大大增加。在进行网格划分时,应注意网格划分的有效性和合理性。 3 网格划分的有效性和合理性 (1)根据分析数据的类型选择合理的网格划分数量 在决定网格数量时应考虑分析数据的类型。在静力分析时,如果仅仅是计算结构的变形,网格数量可以少一些。如果需要计算应力,则在精度要求相同的情况下取相对较多的网格。同样在响应计算中,计算应力响应所取的网格数应比计算位移响应多。在计算结构固有动力特性时,若仅仅是计算少数低阶模态,可以选择较少的网格。如果计算的模态阶次较高,则应选择较多的网格。在热分析中,结构内部的温度梯度不大,不需要大量的内部单元,可划分较少的网格。 (2)根据分析数据的分布特点选择合理的网格疏密度 在决定网格疏密度时应考虑计算数据的分布特点,在计算固有特性时,因为固有频率和振型主要取决于结构质量分布和刚度分布,采用均匀网格可使结构刚度矩阵和质量矩阵的元素不致相差很大,可减小数值计算误差。同样,在结构温度场计算中也趋于采用均匀的网格形式。在计算数据变化梯度较大的部位时,为了更好地反映数据变化规律,需要采用比较密集的网格,而在计算数据变化梯度较小的部位,为了减小模型规模,则应划分相对稀疏的网格,这样整个结构就表现出疏密不同的网格划分形式。 以齿轮轮齿的有限元分析模型为例,由于分析的目的是求出齿轮啮合传动过程中齿根部分的弯曲应力,因此,分析计算时并不需要对整个齿轮进行计算,可根据圣文男原理将整个区域缩小到直接参与啮合的轮齿。虽然实际上参与啮合的齿数总大于1,但考虑到真正起作用的是单齿,通常只取一个轮齿作为分析对象,这样作可以大大节省计算机内存。考虑到轮齿应力在齿根过渡圆角和靠近齿面处变化较大,网格可划分得密一些。在进行疏密不同网格划分操作时可采用ANSYS提供的网格细化工具调整网格的疏密,也可采用分块建模法设置网格疏密度。 图1所示即为采用分块建模法进行网格划分。图1(a)为内燃机中重要运动零件连杆的有限元应力分析图,由于连杆结构对称于其摆动的中间平面,其厚度方向的尺寸远小于长度方向的尺寸,且载荷沿厚度方向近似均匀分布,故可按平面应力分析处 38 煤 矿 机 械 2005年第1期 巴尔扎克 1、巴尔扎克的文学史地位 巴尔扎克是法国伟大的小说家,是19世纪批判现实主义文学的主要代表。在20年间呕心沥血写作实践中,巴尔扎克在世界文学史上构筑了一座举世无双的巍峨大厦——《人间喜剧》,而他自己则成了“文学中的拿破仑”。 马克思非常推崇巴尔扎克,认为他“对现实关系具有深刻理解”。恩格斯赞誉他的作品有着“了不起的革命辩证法”,并在《致玛·哈克奈斯》一信中对他作了精辟的论述。 2、生平与创作概况 A.全称: xx·xx·巴尔扎克 B.本姓: xx C.生卒____年__月__日: 1799.5.20— 1850.8.18 D.出生地: xx E.家庭: 中产阶级之家 F.教育:1816年结束中学学业 G.主要经历: 1819-1829年,开始写作小说; 1825年起出版图书,开办印刷厂,铸造铅字,以欠债6万法郎告终; 1828-1850年,全力创作《人间喜剧》。 H.主要成就: 包括90余部长篇小说、中篇小说、短篇小说的文学巨著《人间喜剧》。 3、巴尔扎克的创作道路 1819-1829年,探索阶段;1819年,立志当作家。1820年,写作悲剧《克伦威尔》失败,开始创作神怪小说,也未获成功。此后至1828年前,屡屡经商失败,债台高筑。1828年夏起重走文学道路。1929年以真名发表历史小说《朱安党人》,初获成功,在文坛站稳脚跟。 1829-1845年,黄金时代;巴尔扎克怀着做“文学上的拿破仑”的雄心壮志,孜孜不倦地创作,建构着《人间喜剧》这座艺术大厦,接连发表了许多杰作,如《高布赛克》 (1830)、《驴皮记》 (1831)、《xx·xx》 (1833)、《xx》 (1834)、《无神论者做弥撒》 (1836)、《xx银行》 (1837)、《幻灭》(1837-1843)和《农民》 (1845)等。 1846-1850年,晚期。1848年前,巴尔扎克陆续完成了《贝姨》 CATIA有限元高级网格划分教程 盛选禹李明志 1.1进入高级网格划分工作台 (1)打开例题中的文件Sample01.CATPart。 (2)点击主菜单中的【开始】→【分析与模拟】→【Advanced Meshing Tools】(高级网格划分工具),就进入【Advanced Meshing Tools】(高级网格划分工具)工作台,如图1-1所示。进入工作台后,生成一个新的分析文件,并且显示一个【New Analysis Case】(新分析算题)对话框,如图1-2所示。 图1-1【开始】→【分析与模拟】→【Advanced Meshing Tools】(高级网格划分工具)(3)在【New Analysis Case】(新分析算题)对话框内选择【Static Analysis】(静力分析)选项。如果以后打开该对话框的时候均希望是计算静力分析,可以把对话框内的【Keep as default starting analysis case】(在开始时保持为默认选项)勾选。这样,下次进入本工作台时,将自动选择静力分析。 (4)点击【新分析算题】对话框内的【确定】按钮,关闭对话框。 1.2定义曲面网格划分参数 本节说明如何定义一个曲面零件的网格类型和全局参数。 (1)点击【Meshing Method】(网格划分方法)工具栏内的【高级曲面划分】按钮 ,如图1-3所示。需要在【Meshing Method】(网格划分方法)工具栏内点击中间按钮的下拉箭头才能够显示出【高级曲 面划分】按钮。 图1-2【New Analysis Case】(新分析算题)对话框图1-3【高级曲面划分】按钮 有限元网格划分 摘要:总结近十年有限元网格划分技术发展状况。首先,研究和分析有限元网格划分的基本原则;其次,对当前典型网格划分方法进行科学地分类,结合实例,系统地分析各种网格划分方法的机理、特点及其适用范围,如映射法、基于栅格法、节点连元法、拓扑分解法、几何分解法和扫描法等;再次,阐述当前网格划分的研究热点,综述六面体网格和曲面网格划分技术;最后,展望有限元网格划分的发展趋势。 关键词:有限元网格划分;映射法;节点连元法;拓扑分解法;几何分解法;扫描法;六面体网格 1 引言 有限元网格划分是进行有限元数值模拟分析至关重要的一步,它直接影响着后续数值计算分析结果的精确性。网格划分涉及单元的形状及其拓扑类型、单元类型、网格生成器的选择、网格的密度、单元的编号以及几何体素。在有限元数值求解中,单元的等效节点力、刚度矩阵、质量矩阵等均用数值积分生成,连续体单元以及壳、板、梁单元的面内均采用高斯(Gauss)积分,而壳、板、梁单元的厚度方向采用辛普生(Simpson)积分。 2 有限元网格划分的基本原则 有限元方法的基本思想是将结构离散化,即对连续体进行离散化,利用简化几何单元来近似逼近连续体,然后根据变形协调条件综合求解。所以有限元网格的划分一方面要考虑对各物体几何形状的准确描述,另一方面也要考虑变形梯度的准确描述。为正确、合理地建立有限元模型,这里介绍划分网格时应考虑的一些基本原则。 2.1 网格数量 网格数量直接影响计算精度和计算时耗,网格数量增加会提高计 算精度,但同时计算时耗也会增加。当网格数量较少时增加网格,计算精度可明显提高,但计算时耗不会有明显增加;当网格数量增加到一定程度后,再继续增加网格时精度提高就很小,而计算时耗却大幅度增加。所以在确定网格数量时应权衡这两个因素综合考虑。 2.2 网格密度 为了适应应力等计算数据的分布特点,在结构不同部位需要采用大小不同的网格。在孔的附近有集中应力,因此网格需要加密;周边应力梯度相对较小,网格划分较稀。由此反映了疏密不同的网格划分原则:在计算数据变化梯度较大的部位,为了较好地反映数据变化规律,需要采用比较密集的网格;而在计算数据变化梯度较小的部位,为减小模型规模,网格则应相对稀疏。 2.3 单元阶次 单元阶次与有限元的计算精度有着密切的关联,单元一般具有线性、二次和三次等形式,其中二次和三次形式的单元称为高阶单元。高阶单元的曲线或曲面边界能够更好地逼近结构的曲线和曲面边界,且高次插值函数可更高精度地逼近复杂场函数,所以增加单元阶次可提高计算精度。但增加单元阶次的同时网格的节点数也会随之增加,在网格数量相同的情况下由高阶单元组成的模型规模相对较大,因此在使用时应权衡考虑计算精度和时耗。 2.4 单元形状 网格单元形状的好坏对计算精度有着很大的影响,单元形状太差的网格甚至会中止计算。单元形状评价一般有以下几个指标: (1)单元的边长比、面积比或体积比以正三角形、正四面体、正六面体为参考基准。 (2)扭曲度:单元面内的扭转和面外的翘曲程度。 (3)节点编号:节点编号对于求解过程中总刚矩阵的带宽和波前因数有较大的影响,从而影响计算时耗和存储容量的大小 2.5 单元协调性 单元协调是指单元上的力和力矩能够通过节点传递给相邻单元。为保证单元协调,必须满足的条件是: (1)一个单元的节点必须同时也是相邻点,而不应是内点或边界 一、基本有限元网格概念 1.单元概述?几何体划分网格之前需要确定单元类型.单元类型的选择应该根据分析类型、形状特征、计算数据特点、精度要求和计算的硬件条件等因素综合考虑。为适应特殊的分析对象和边界条件,一些问题需要采用多种单元进行组合建模。? 2.单元分类选择单元首先需要明确单元的类型,在结构有限元分析中主要有以下一些单元类型:平面应力单元、平面应变单元、轴对称实体单元、空间实体单元、板单元、壳单元、轴对称壳单元、杆单元、梁单元、弹簧单元、间隙单元、质量单元、摩擦单元、刚体单元和约束单元等。根据不同的分类方法,上述单元可以分成以下不同的形式。?3。按照维度进行单元分类 根据单元的维数特征,单元可以分为一维单元、二维单元和三维单元。?一维单元的网格为一条直线或者曲线。直线表示由两个节点确定的线性单元。曲线代表由两个以上的节点确定的高次单元,或者由具有确定形状的线性单元。杆单元、梁单元和轴对称壳单元属于一维单元,如图1~图3所示。 ?二维单元的网 格是一个平面或者曲面,它没有厚度方向的尺寸.这类单元包括平面单元、轴对称实体单元、板单元、壳单元和复合材料壳单元等,如图4所示。二维单元的形状通常具有三角形和四边形两种,在使用自动网格剖分时,这类单元要求的几何形状是表面模型或者实体模型的边界面。采用薄壳单元通常具有相当好的计算效率。 ??三维单元的网格具有空间三个方向的尺寸,其形状具有四面体、五面体和六面体,这类单元包括空间实体单元和厚壳单元,如图5所示.在自动网格划分时,它要求的是几何模型是实体模型(厚壳单元是曲面也可以)。 ? 4.按照插值函数进行单元分类 根据单元插值函数多项式的最高阶数多少,单元可以分为线性单元、二次单元、三次单元和更高次的单元。 线性单元具有线性形式的插值函数,其网格通常只具有角节点而无边节点,网格边界为直线或者平面.这类单元的优点是节点数量少,在精度要求不高或者结果数据梯度不太大的情况下,采用线性单元可以得到较小的模型规模.但是由于单元位移函数是线性的,单元内的位移呈线性变化,而应力是常数,因此会造成单元间的应力不连续,单元边界上存在着应力突变,如图6所示。 题目:请比较PageRank算法和HITS算法的优缺点,除此之外,请再介绍2种用于搜索引擎检索结果的排序算法,并举例说明。 答: 1998年,Sergey Brin和Lawrence Page[1]提出了PageRank算法。该算法基于“从许多优质的网页链接过来的网页,必定还是优质网页”的回归关系,来判定网页的重要性。该算法认为从网页A导向网页B的链接可以看作是页面A对页面B的支持投票,根据这个投票数来判断页面的重要性。当然,不仅仅只看投票数,还要对投票的页面进行重要性分析,越是重要的页面所投票的评价也就越高。根据这样的分析,得到了高评价的重要页面会被给予较高的PageRank值,在检索结果内的名次也会提高。PageRank是基于对“使用复杂的算法而得到的链接构造”的分析,从而得出的各网页本身的特性。 HITS 算法是由康奈尔大学( Cornell University ) 的JonKleinberg 博士于1998 年首先提出。Kleinberg认为既然搜索是开始于用户的检索提问,那么每个页面的重要性也就依赖于用户的检索提问。他将用户检索提问分为如下三种:特指主题检索提问(specific queries,也称窄主题检索提问)、泛指主题检索提问(Broad-topic queries,也称宽主题检索提问)和相似网页检索提问(Similar-page queries)。HITS 算法专注于改善泛指主题检索的结果。 Kleinberg将网页(或网站)分为两类,即hubs和authorities,而且每个页面也有两个级别,即hubs(中心级别)和authorities(权威级别)。Authorities 是具有较高价值的网页,依赖于指向它的页面;hubs为指向较多authorities的网页,依赖于它指向的页面。HITS算法的目标就是通过迭代计算得到针对某个检索提问的排名最高的authority的网页。 通常HITS算法是作用在一定范围的,例如一个以程序开发为主题的网页,指向另一个以程序开发为主题的网页,则另一个网页的重要性就可能比较高,但是指向另一个购物类的网页则不一定。在限定范围之后根据网页的出度和入度建立一个矩阵,通过矩阵的迭代运算和定义收敛的阈值不断对两个向量authority 和hub值进行更新直至收敛。 从上面的分析可见,PageRank算法和HITS算法都是基于链接分析的搜索引擎排序算法,并且在算法中两者都利用了特征向量作为理论基础和收敛性依据。 巴尔扎克作品经典语录大全100句 1、男子的才对于德而言,就和美貌之于女子差不多:能给人以希望。——巴尔扎克《莫黛斯特·米尼翁婚约》 2、苦难好比一道神奇的符箓,能加强我们的天性,使猜忌与凶恶的人愈加猜忌愈加凶恶,慈悲的人愈加慈悲。——巴尔扎克《夏倍上校》 3、真正的考验是在痛苦和幸福上。当两个人通过了这两种人生的考验,在这过程中每人的优缺点都暴露无遗,也观察了彼此的性格时,他们就可以手携手一直走到坟墓了。——巴尔扎克《莫黛斯特·米尼翁婚约》 4、在爱情方面,别有用心的虚假总比真面目可爱,就因为此,才有许多男人肯在一般手段高明的女骗子身上挥金如土。——巴尔扎克 5、人类所有的力量,只是耐心加上时间的混合。所谓强者是既有意志,又能等待时机。守财奴的生活,便是不断的运用这种力量为自我效劳。他只依赖两种情感:自尊心与利益。但利益既是自尊心的实际表现并且是真正优越的凭据,所以自尊心与利益是一物的两面,都从自私自利来的。这种人物涉及所有的情感,可以说集情感之大成,而我们个个人都跟他们一脉相通。哪有什么全无欲望的人?而没有金钱,哪个欲望够满足?——巴尔扎克《欧叶妮·葛朗台》 6、精神生活与肉体生活一样,有呼也有吸:灵魂吸收另一颗灵魂的感情来充实自己,然后以更丰富的感情送回给人家。人与人之间要没有这点美妙的关系,心就没有了生机:它缺少空气,它会受难,枯萎。——巴尔扎克《欧叶妮·葛朗台》 7、逆境不就是命运的试金石吗? ——巴尔扎克《高 老头》8、"L'amour n'est pas seulement un sentiment, il est aussi un art. 爱不光是一种感情,也是一门艺术。- Honoréde Balzac 巴尔扎克-——巴尔扎克《网络名言集》"9、感情等于才分。感受是了解的对手,正如行动是思维的抗衡。一个有天才的朋友可以通过友情、领会,和他并驾齐驱。一个常人有感情作基础,就可以比倒最伟大的艺术家。这说明女人为什么爱着一些“蠢才”。——巴尔扎克10、到处是真苦难,假欢喜。——巴尔扎克《高老头》11、哪里有穷困,哪里就有苦难。苦难,穷困,蓄势极猛,苦了,穷了,斯滥矣,大权在握,就会滥用,其理自同。——巴尔扎克《乡村医生》12、做点好事,待人要仁慈、宽厚;总之,用你的谦虚来避免厄运吧。——巴尔扎克13、苦难对于人生是一块垫脚石……对于能干的人是一笔财富,对于弱者是个万丈深渊。——巴尔扎克14、目的高尚,会使所做的事情都同样高尚。——巴尔扎克15、实笃一清如水的生活,诚实不欺的性格,不论身处哪个阶级,就算心术最坏的人,也会对之肃然起敬。——巴尔扎克16、长命也许不够好,美好的生命却够长。——巴尔扎克17、人们有多少需求,就能创造多少财富。——巴尔扎克18、艺术就是用最小的面积,惊人地集中最大量思想。——巴尔扎克19、他不断地处于与人奋斗、与天地奋斗之中,没有功夫去尽情卖弄。只有花花公子才会大肆卖弄,迫不及待地将转瞬即逝的一季庄稼收割下来,那种自尊与不管是什么东西,凡从它手下经过就要抽税的海关相差无几。——巴尔扎克20、年轻时费过力气学到的东西,即使是无聊对我们也有用。——巴尔扎克21、拐弯抹角的路成不了 ANSYS有限元网格划分的基本要点 1引言 ANSYS有限元网格划分是进行数值模拟分析至关重要的一步,它直接影响着后续数值计算分析结果的精确性。网格划分涉及单元的形状及其拓扑类型、单元类型、网格生成器的选择、网格的密度、单元的编号以及几何体素。从几何表达上讲,梁和杆是相同的,从物理和数值求解上讲则是有区别的。同理,平面应力和平面应变情况设计的单元求解方程也不相同。在有限元数值求解中,单元的等效节点力、刚度矩阵、质量矩阵等均用数值积分生成,连续体单元以及壳、板、梁单元的面内均采用高斯(Gauss)积分,而壳、板、梁单元的厚度方向采用辛普生(Simpson)积分。辛普生积分点的间隔是一定的,沿厚度分成奇数积分点。由于不同单元的刚度矩阵不同,采用数值积分的求解方式不同,因此实际应用中,一定要采用合理的单元来模拟求解。 2ANSYS网格划分的指导思想 ANSYS网格划分的指导思想是首先进行总体模型规划,包括物理模型的构造、单元类型的选择、网格密度的确定等多方面的内容。在网格划分和初步求解时,做到先简单后复杂,先粗后精,2D单元和3D单元合理搭配使用。为提高求解的效率要充分利用重复与对称等特征,由于工程结构一般具有重复对称或轴对称、镜象对称等特点,采用子结构或对称模型可以提高求解的效率和精度。利用轴对称或子结构时要注意场合,如在进行模态分析、屈曲分析整体求解时,则应采用整体模型,同时选择合理的起点并设置合理的坐标系,可以提高求解的精度和效率,例如,轴对称场合多采用柱坐标系。有限元分析的精度和效率与单元的密度和几何形状有着密切的关系,按照相应的误差准则和网格疏密程度,避免网格的畸形。在网格重划分过程中常采用曲率控制、单元尺寸与数量控制、穿透控制等控制准则。在选用单元时要注意剪力自锁、沙漏和网格扭曲、不可压缩材料的体积自锁等问题 ANSYS软件平台提供了网格映射划分和自由适应划分的策略。映射划分用于曲线、曲面、实体的网格划分方法,可使用三角形、四边形、四面体、五面体和六面体,通过指定单元边长、网格数量等参数对网格进行严格控制,映射划分只用于规则的几何图素,对于裁剪曲面或者空间自由曲面等复杂几何体则难以 巴尔扎克出生于一个法国大革命后致富的资产阶级家庭,法科学校毕业后,拒绝家庭为他 选择的受人尊敬的法律职业,而立志当文学家。为了获得独立生活和从事创作的物质保障,他曾试笔并插足商业,从事出版印刷业,但都以破产告终。这一切都为他认识社会、描写 社会提供了极为珍贵的第一手材料。他不断追求和探索,对哲学、经济学、历史、自然科学、神学等领域进行了深入研究,积累了极为广博的知识。 1822年正当巴尔扎克倍受冷遇,痛苦绝望的时刻,结识了贝尔尼夫人。贝尔尼夫人的母亲 曾是王后的侍女,对宫廷的生活,交际的秘密和妇女的命运十分熟悉。贝尔尼夫人比巴尔 扎克大22岁,具有完美的娇柔感,高雅的谈吐,沁人肺腑的同情心,以及慈祥的母爱。这一切深深吸引着巴尔扎克,使巴尔扎克感受到从小没有领略过的母爱般的温情。她对他的 一生产生了重大的影响。巴尔扎克把她称为他的母亲、朋友、家属、伴侣和顾问。[1] 1829年,巴尔扎克完成长篇小说《朱安党人》。历史小说《朱安党人》(1829)是巴尔扎 克用真名发表的 奥诺雷·德·巴尔扎克 第一部作品,描述1800年法国布列塔尼在保皇党煽动下发生的反对共和国政府的暴动。作者赋予英勇的共和国军人以应有的光彩,但也大大美化了朱安党首领孟多兰侯爵,表现出 他当时对贵族的同情。为了写这部小说,他曾细心研究有关暴动的历史文献,亲自去布列 塔尼调查山川形势和农民生活,访问暴动的目击者和参加者,还从友人柏尔里公爵夫人那 里收集许多关于朱安党人的掌故。从写神怪小说过渡到写历史小说,是巴尔扎克走向批判 现实主义的第一个重要步骤。他在《朱安党人》中描写的不是古代历史,而是属于当代社 会生活范畴的重要事件。着重反映当代社会生活,正是巴尔扎克日后所写的《人间喜剧》 的一个特点。 从1829年写《朱安党人》起,巴尔扎克的创作开始进入成熟时期,即《人间喜剧》时期(1829-1848)。在三、四十年代,他除致力于文艺创作以外,还出入巴黎上流社会的沙龙,为几种报刊撰稿,他接触的生活面非常广泛。[2] 巴尔扎克从这时期起,就在现实主义理论方面进行深入探索。他认为小说家必须面向现实 生活,使自己成为当代社会的风俗史家;又认为小说家的任务不仅在于摹写社会现象,还 须阐明产生这些现象的原因,指出人物、 影视剧中奥诺雷·德·巴尔扎克 欲念和事件背后的意义。在塑造人物的问题上,他强调特性,也强调共性;他说诗人的使 命在创造典型,使典型个性化,个性典型化;又说典型人物应该把那些多少和他类似的人 的性格特点集于一身。他还强调艺术必须为社会服务;认为艺术家不仅描写罪恶和德行, 而且要指出其中的教育意义;艺术家必须同时是道德家和政治家。 1830年4月,巴尔扎克《人间喜剧》中《私人生活场景》两卷出版了。然而,他深深地为 法国文学创作者的处境担忧。虽然法国于1791年颁布的《表演法令》和1793年颁布的 ANSYS有限元分析中的网格划分 有限元分析中的网格划分好坏直接关系到模型计算的准确性。本文简述了网格划分应用的基本理论,并以ANSYS限元分析中的网格划分为实例对象,详细讲述了网格划分基本理论及其在工程中的实际应用,具有一定的指导意义。 作者: 张洪才 关键字: CAE ANSYS 网格划分有限元 1 引言 ANSYS有限元网格划分是进行数值模拟分析至关重要的一步,它直接影响着后续数值计算分析结果的精确性。网格划分涉及单元的形状及其拓扑类型、单元类型、网格生成器的选择、网格的密度、单元的编号以及几何体素。从几何表达上讲,梁和杆是相同的,从物理和数值求解上讲则是有区别的。同理,平面应力和平面应变情况设计的单元求解方程也不相同。在有限元数值求解中,单元的等效节点力、刚度矩阵、质量矩阵等均用数值积分生成,连续体单元以及壳、板、梁单元的面内均采用高斯(Gauss)积分,而壳、板、梁单元的厚度方向采用辛普生(Simpson)积分。辛普生积分点的间隔是一定的,沿厚度分成奇数积分点。由于不同单元的刚度矩阵不同,采用数值积分的求解方式不同,因此实际应用中,一定要采用合理的单元来模拟求解。 2 ANSYS网格划分的指导思想 ANSYS网格划分的指导思想是首先进行总体模型规划,包括物理模型的构造、单元类型的选择、网格密度的确定等多方面的内容。在网格划分和初步求解时,做到先简单后复杂,先粗后精,2D单元和3D单元合理搭配使用。为提高求解的效率要充分利用重复与对称等特征,由于工程结构一般具有重复对称或轴对称、镜象对称等特点,采用子结构或对称模型可以提高求解的效率和精度。利用轴对称或子结构时要注意场合,如在进行模态分析、屈曲分析整体求解时,则应采用整体模型,同时选择合理的起点并设置合理的坐标系,可以提高求解的精度和效率,例如,轴对称场合多采用柱坐标系。有限元分析的精度和效率与单元的密度和几何形状有着密切的关系,按照相应的误差准则和网格疏密程度,避免网格的畸形。在网格重划分过程中常采用曲率控制、单元尺寸与数量控制、穿透控制等控制准则。在选用单元时要注意剪力自锁、沙漏和网格扭曲、不可压缩材料的体积自锁等问题ANSYS软件平台提供了网格映射划分和自由适应划分的策略。映射划分用于曲线、曲面、实体的网格划分方法,可使用三角形、四边形、四面体、五面体和六面体,通过指定单元边长、网格数量等参数对网格进行严格控制,映射划分只用于规则的几何图素,对于裁剪曲面或者空间自由曲面等复杂几何体则难以控制。自由网格划分用于空间自由曲面和复杂实体,采用三角形、四边形、四面体进行划分,采用网格数量、边长及曲率来控制网格的质量。 3 ANSYS网格划分基本原则 3.1 网格数量 网格数量的多少将影响计算结果的精度和计算规模的大小。一般来讲,网格数量增加,计算精度会有所提高,但同时计算规模也会增加,所以在确定网格数量时应权衡两个因数综合考虑。 图1 位移精度和计算时间随网格数量的变化 图1中的曲线1表示结构中的位移随网格数量收敛的一般曲线,曲线2代表计算时间随 结构有限元分析中的网格划分技术及其应用实例 结构有限元分析中的网格划分是否直接关系到解算的效果。本文简述了网格划分应用的基本理论,并以空间自由曲面覆盖件和大型整体网络钢筋壳体产品的有限元分析中的网格划分为实例对象,详细讲述了空间自由和三维实体的网格划分基本理论及其在工程中的实际应用,非常具有现实意义和借鉴价值。 一、前言 有限元网格划分是进行有限元数值模拟分析至关重要的一步,它直接影响着后续数值计算分析结果的精确性。网格划分涉及单元的形状及其拓扑类型、单元类型、网格生成器的选择、网格的密度、单元的编号以及几何体素。从几何表达上讲,梁和杆是相同的,从物理和数值求解上讲则是有区别的。同理,平面应力和平面应变情况设计的单元求解方程也不相同。在有限元数值求解中,单元的等效节点力、刚度矩阵、质量矩阵等均用数值积分生成,连续体单元以及壳、板、梁单元的面内均采用高斯(Gauss)积分,而壳、板、梁单元的厚度方向采用辛普生(Simpson)积分。辛普生积分点的间隔是一定的,沿厚度分成奇数积分点。由于不同单元的刚度矩阵不同,采用数值积分的求解方式不同,因此实际应用中,一定要采用合理的单元来模拟求解。 CAD软件中流行的实体建模包括基于特征的参数化建模和空间自由曲面混合造型两种 方法。Pro/E和SoildWorks是特征参数化造型的代表,而 CATIA与Unigraphics等则将特征参数化和空间自由曲面混合造型有机的结合起来。现有CAD软件对表面形态的表示法已经大大超过了CAE软件,因此,在将CAD实体模型导入CAE软件的过程中,必须将CAD模型中其他表示法的表面形态转换到CAE软件的表示法上,转换精度的高低取决于接口程序的好坏。在转换过程中,程序需要解决好几何图形(曲线与曲面的空间位置)和拓扑关系(各图形数据的逻辑关系)两个关键问题。其中几何图形的传递相对容易实现,而图形间的拓扑关系容易出现传递失败的情况。数据传递面临的一个重大挑战是,将导入CAE程序的CAD模型改造成适合有限元分析的网格模型。在很多情况下,导入CAE程序的模型可能包含许多设计细节,如细小的孔、狭窄的槽,甚至是建模过程中形成的小曲面等。这些细节往往不是基于结构的考虑,保留这些细节,单元数量势必增加,甚至会掩盖问题的主要矛盾,对分析结果造成负面影响。 CAD模型的“完整性”问题是困扰网格剖分的障碍之一。对于同一接口程序,数据传递的品质取决于CAD模型的精度。部分CAD模型对制造检测来说具备足够的精度,但对有限元网格剖分来说却不能满足要求。值得庆幸的是,这种问题通常可通过CAD软件的“完整性检查”来修正。改造模型可取的办法是回到CAD系统中按照分析的要求修改模型。一方面检查模型的完整性,另一方面剔除对分析无用的细节特征。但在很多情况下,这种“回归”很难实现,模型的改造只有依靠 CAE软件自身。CAE中最直接的办法是依靠软件具有的“重构”功能,即剔除细部特征、缝补面和将小面“融入”大曲面等。有些专用接口在模型传递过程中甚至允许自动完成这种工作,并且通过网格剖分器检验模型的“完整性”,如发现“完整性”不能满足要求,接口程序可自动进行“完整性”修复。当几何模型距 CAE分析的要求相差太大时,还可利用CAE程序的造型功能修正几何模型。“布尔运算”是切除细节和修理非完整特征的有效工具之一。 目前数据传递一般可通过专用数据接口,CAE程序可与CAD程序“交流”后生成与CAE 程序兼容的数据格式。另一种方式是通过标准图形格式如IGES、 SAT和ParaSolid传递。现有的CAD平台与通用有限元平台一般通过IGES、STL、Step、Parasolid等格式来数据交 第五节巴尔扎克与《高老头》分析 一、巴尔扎克简介(1799-1850) 1、《人间喜剧》的创作:《风俗研究》《哲理研究》《分析研究》,是一部关于19世纪法国的“包罗万象的社会史”。 (1)主题上要写出“一个完整的社会”,艺术上要呈现一个“统一、独创、新鲜的整体”。 (2)主题思想:反映出资产阶级取代贵族阶级的时代潮流。 A、资产阶级的发迹史。《赛查·皮罗托盛衰记》《欧也妮·葛朗台》《纽沁根银行》 B、贵族阶级的衰亡史。《古物陈列室》 C、金钱成为社会的轴心,操纵着社会关系,这不仅反映在广义的政界、社交界等社会层面,而且反映在最亲密的家庭关系中。 (3)艺术特征: A、艺术形式的多样化和富于变化,或客观描述,或转述故事,或深入人们的情感中探讨。 B、在典型环境中塑造具有典型意义的人物形象,人物性格与物质化的社会环境水乳交融。 C、作品文本的相互交织。《人间喜剧》的一部作品中的人物形象会在多部作品中出现,人物的命运具有时间上的连续性,因而众多作品相互勾连,构成一部完整的社会生活的记录。如《高老头》中鲍赛昂夫人的凄凉结局、拉斯蒂涅的飞黄腾达。 D、写实与幻想交相辉映,突出金钱统治下的法国社会的疯狂喧嚣。《萨拉辛》 二、《高老头》分析([法]巴尔扎克著,张冠尧译,北京:人民文学出版社,2003年) 一、作品背景与主要内容介绍 当时的法国现实是,资产阶级已经获得彻底的胜利,而贵族阶级逐渐地退出历史舞台。这样资本主义的生产关系的重要基础即金钱在社会生活中占据着绝对地位,支配着各种社会关系,并且渗透在人们的亲情、友情和爱情中。 《高老头》是法国批判现实主义大师巴尔扎克最具代表性的作品之一,充分展现了金钱的罪恶与对人类美好感情与人性的腐蚀作用。 二、作品简介 作品中有着两条线索,一条是高老头的命运正由盛转向衰败,另一条是拉斯蒂涅正步步高升,但展现的是相同主题。拉斯蒂涅为高老头奔走于两地之间,作品通过他的奔走将这两条线索结合起来,凸现法国巴黎各个社会阶层的生活。从代表着法国社会底层的缩影的伏盖公寓,到法国的上流社会人人趋之若骛的地方鲍赛昂夫人的门庭和舞会;从社会的底层人物伏盖公寓中住客之间的关系,到贵族与银行家的家庭关系,《高老头》描写得详尽细致,淋漓尽致。与法国社会各阶层的接触使拉斯蒂涅逐步认识到法国社会的本质,即金钱至上,人人为己,但这也使他彻底泯灭的人性的良知。 三、作品主题 1、金钱主宰着社会的一切关系 2、高老头的沦落意味着,在资本阶级上升时期金钱对社会的统治和金钱至上的原则的冲击下,传统的宗法制家庭伦理关系彻底解体。 四、拉斯蒂涅的人物形象分析 作者塑造高老头人物形象的意义,不仅是想通过高老头的命运对作品中另一主要人物拉斯蒂涅发生重要的作用,让拉斯蒂涅再一次受到了资产阶级自私自利 A N S Y S有限元网格划 分的基本原则 ANSYS有限元网格划分的基本原则 发表时间:2009-4-3 作者: 张洪才 关键字: CAE ANSYS 网格划分有限元 有限元分析中的网格划分好坏直接关系到模型计算的准确性。本文简述了网格划分应用的基本理论,并以ANSYS限元分析中的网格划分为实例对象,详细讲述了网格划分基本理论及其在工程中的实际应用,具有一定的指导意义。 1 引言 ANSYS有限元网格划分是进行数值模拟分析至关重要的一步,它直接影响着后续数值计算分析结果的精确性。网格划分涉及单元的形状及其拓扑类型、单元类型、网格生成器的选择、网格的密度、单元的编号以及几何体素。 从几何表达上讲,梁和杆是相同的,从物理和数值求解上讲则是有区别的。同理,平面应力和平面应变情况设计的单元求解方程也不相同。 在有限元数值求解中,单元的等效节点力、刚度矩阵、质量矩阵等均用数值积分生成,连续体单元以及壳、板、梁单元的面内均采用高斯(Gauss)积分,而壳、板、梁单元的厚度方向采用辛普生(Simpson)积分。辛普生积分点的间隔是一定的,沿厚度分成奇数积分点。由于不同单元的刚度矩阵不同,采用数值积分的求解方式不同,因此实际应用中,一定要采用合理的单元来模拟求解。 2 ANSYS网格划分的指导思想 ANSYS网格划分的指导思想是首先进行总体模型规划,包括物理模型的构造、单元类型的选择、网格密度的确定等多方面的内容。 在网格划分和初步求解时,做到先简单后复杂,先粗后精,2D单元和3D 单元合理搭配使用。为提高求解的效率要充分利用重复与对称等特征,由于工程结构一般具有重复对称或轴对称、镜象对称等特点,采用子结构或对称模型可以提高求解的效率和精度。利用轴对称或子结构时要注意场合,如在进行模态分析、屈曲分析整体求解时,则应采用整体模型,同时选择合理的起点并设置合理的坐标系,可以提高求解的精度和效率,例如,轴对称场合多采用柱坐标系。有限元分析的精度和效率与单元的密度和几何形状有着密切的关系,按照相应的误差准则和网格疏密程度,避免网格的畸形。在网格重划分过程中常采用曲率控制、单元尺寸与数量控制、穿透控制等控制准则。在选用单元时要注意剪力自锁、沙漏和网格扭曲、不可压缩材料的体积自锁等问题 ANSYS软件平台提供了网格映射划分和自由适应划分的策略。映射划分用于曲线、曲面、实体的网格划分方法,可使用三角形、四边形、四面体、五面体和六面体,通过指定单元边长、网格数量等参数对网格进行严格控制,映射划分只用于规则的几何图素,对于裁剪曲面或者空间自由曲面等复杂几何体则难以控制。自由网格划分用于空间自由曲面和复杂实体,采用三角形、四边形、四面体进行划分,采用网格数量、边长及曲率来控制网格的质量。巴尔扎克简介

高中语文 名著导读《高老头》巴尔扎克简介素材 新人教版必修3

有限元网格划分心得

_基于ANSYS的有限元法网格划分浅析

巴尔扎克

CATIA有限元高级划分网格教程

有限元网格划分

有限元网格划分和收敛性

比较PageRank算法和HITS算法的优缺点

巴尔扎克作品经典语录大全100句

ANSYS有限元网格划分的基本要点

巴尔扎克——素材

ANSYS有限元分析中的网格划分

有限元网格划分方法与基本原理

外国文学史 巴尔扎克汇编

最新ANSYS有限元网格划分的基本原则汇总

相关文档

- 有限元网格划分注意事项

- 有限元网格划分

- CATIA有限元高级划分网格教程

- 有限元网格划分的基本规则

- 有限元分析网格划分

- ANSYS有限元网格划分的基本要点

- 有限元网格划分注意事项

- 有限元网格划分的基本原则

- CATIA有限元高级划分网格教程

- 最新ANSYS有限元网格划分的基本原则汇总

- 有限元计算单元网格划分

- 有限元网格划分的基本原则

- 有限元网格划分和收敛性

- 有限元网格划分和收敛性

- 有限元分析培训(第3讲-ANSYS-Workbench网格划分)

- _基于ANSYS的有限元法网格划分浅析

- 有限元网格划分方法与基本原理

- 有限元网格划分和收敛性

- 有限元网格划分注意事项

- 有限元网格划分