CheckList

南京 ? 中国

物理系

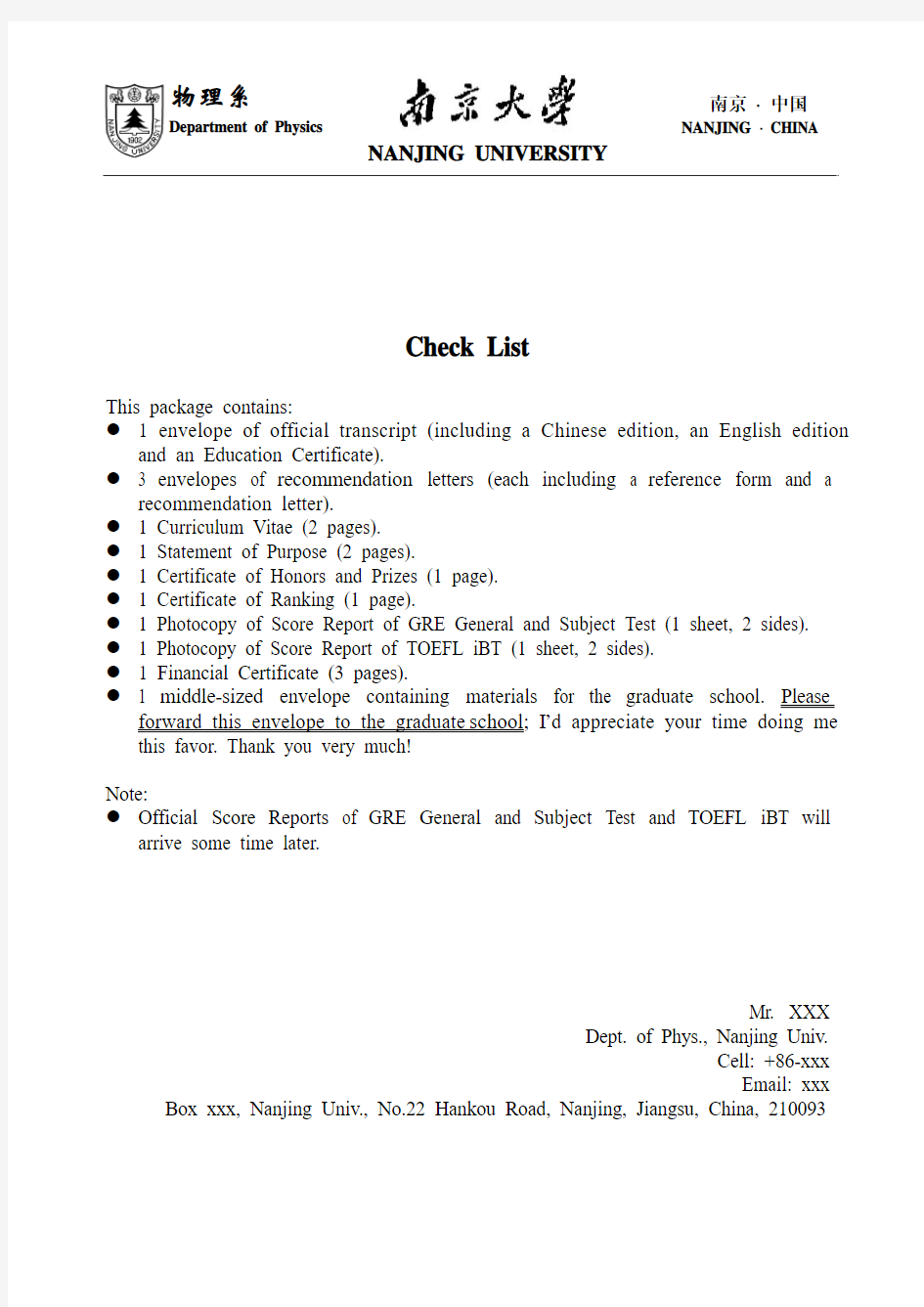

Check List

This package contains:

● 1 envelope of official transcript (including a Chinese edition, an English edition

and an Education Certificate).

● 3 envelopes of recommendation letters (each including a reference form and a

recommendation letter).

● 1 Curriculum Vitae (2 pages). ● 1 Statement of Purpose (2 pages).

● 1 Certificate of Honors and Prizes (1 page). ● 1 Certificate of Ranking (1 page).

● 1 Photocopy of Score Report of GRE General and Subject Test (1 sheet, 2 sides). ● 1 Photocopy of Score Report of TOEFL iBT (1 sheet, 2 sides). ● 1 Financial Certificate (3 pages).

● 1 middle-sized envelope containing materials for the graduate school. Please

forward this envelope to the graduate school; I ’

Note:

● Official Score Reports of GRE General and Subject Test and TOEFL iBT will

arrive some time later.

Mr. XXX

Dept. of Phys., Nanjing Univ.

Cell: +86-xxx Email: xxx

Box xxx, Nanjing Univ., No.22 Hankou Road, Nanjing, Jiangsu, China, 210093

PPAP检查清单Checklist(中英文)

No. 序号 PPAP Element PPAP 文件种类递交Yes 无要求递交N/A Remarks 备注1 Completed part submission warrant (PSW)完整的零件提交保证书(PSW)2 Appearance approval report approved (AAR)经批准的外观批准报告(AAR)3 Design records with PE approval /sign-off.产品工程批准的设计记录零件图纸,有关的工程文件;规范4PE approved engineering. change Documents for the part(If any). 产品工程批准的工程更改文件,如果有5Dimension checked print for all parts (Inclusive assembly or sub-parts) 对所有零件尺寸检查标识-包含总成、零件 6Dimensional report referenced to the check print for # of samples decided. 和尺寸检验标识对应的尺寸报告 7Document of checking fixtures/checking aids used.检具及检查辅具文件 8Material test results summary report (incl. All child parts)with all enclosures in original. 材料测试结果总结报告,包括所有分零件,并附原始报告9a Functional/performance test results-summary report with all enclosures. 功能/性能测试结果总结报告,并附原始报告9b Durability test results-Summary reports in original 耐久性测试结果总结报告,并附原始报告 10Process flow diagram, duly numbered for each operation (co-relate with FMEA & control plan). 过程流程图(工位编号与FMEA 和控制计划一致)11PFMEA 过程失效模式和效果分析 12DFMEA-if supplier is design responsible. 设计失效模式和效果分析-如果供应商是设计责任者13a produciton Control Plan 生产控制计划.13b pre-launch control plan 试生产控制计划 14 Innitial Process capability results 初始过程能力15 MSA 测量系统分析16 Packaging Specifications (If any)包装说明17 Subcontractor list and Bill of material (BOM)分供方清单和物料清单18 Customer Engineering Approval 顾客工程批准OTS 工程认可报告19 Qualified Lab Documentation 实验室认可文件20 Bull Material Requirements Checklist(for Bulk material PPAP only) 散装材料要求检查清单21 Sample Product & Master Sample 生产件样品及标准样品22Records of Compliance with C Specific Requirements 符合顾客其它要求的记录 车型年份: 提交PPAP 的样品数量:Supplier Name 供应商名称 : Completed by (编制): Approved by(批准) : Date(日期 ): PPAP 检查清单/PPAP Checklist Part Name: Part No.:零件名称: 零件编号:Model Year: No. for samples submitted for PPAP:

产品结构设计等方面的checklist

模具的checklist表: 产品名称模具编号材料收缩率 序号内容自检确认 1与客户交流清楚外观面位置及外观要求如镜面,皮纹,亚光等。 2清楚产品的安装方向,产品的出模方向及它们之间的关系。 3产品在出模方向无不合理结构。 4壁厚合理,壁厚均匀,没有过薄,过厚及壁厚突变。 5圆角齐全,所有外观面倒圆角(特殊要求除外),所有非外观面倒圆角,非外观面圆角足够大。且圆角处壁厚均匀,无漏掉的圆角。 6脱模斜度齐全,正确,无放反的情况,脱模斜度足够大,已用DRAFTCHECK命令进行检查。7透明件,皮纹处理的外观面,插穿面脱模斜度足够大,满足标准。 8透明件已考虑外观效果,可见结构,并与客户进行交流。 9需贴膜的件已经考虑到膜在实际安装方向的定位, 10电镀件装配考虑到镀层厚度和装配间隙, 11一面用插接,一面用卡爪的结构已考虑到装配过程中是否有与外观干涉,是否有造成外观面破坏的情况,卡爪是否易断 12加强筋高度,宽度,脱模斜度结构及工艺均合理。 13外观件检查产品结构如壁厚,加强筋(尤其是横在制品侧壁的筋考虑与侧壁的防缩)、螺钉柱等不会引起缩水,已采取防缩措施。 14产品变形,收缩等注塑缺陷轻微,且已与客户协商,得到客户的书面认可。 15需出斜顶,滑块,抽芯的结构活动距离及空间足够,结构能否简化。 16产品无引起模具壁薄,尖角等不合理结构。 17带嵌件的产品考虑嵌件在模具中的牢固固定,内桶底的嵌件要求将嵌件和包嵌件的胶位合并到一起作为模具嵌件。 18与客户交流清楚分型面的位置,外观面滑块,抽芯允许的夹线位置。 19备份产品已检查所有修模报告及更改记录并进行了更改,重要装配尺寸进行了样件的实际测绘验证。 笔记本的CHECKLIST DesignCheckListBySub-Assy. 1.U-Case 1-1上下盖嵌合部份 1-1-1上下盖PL是否Match 1-1-2Lip是否完成,是否符合外观要求(修饰沟) 1-1-3侧壁之TAPER/与下盖是否配合/考虑到开模 1-1-4上下盖之配合卡勾共几处,是否位置match 1-1-5卡勾嵌合深度多少 1-1-6卡勾两侧有无夹持Rib,拆拔时是否易断裂 1-1-7卡勾是否造成侧壁缩水(如果太厚) 1-1-8公模内面形状(如各处高度). 1-1-10PL切口处是否有刀口产生(全周Check) 1-2BOSS 1-2-1上下盖BOSS孔位是否相合 1-2-2BOSS尺寸是否标准化,内缘有没有倒角

(签证材料列表)Checklist-Cultural-latest(1)(1)

Checklist for Taking Part in Cultural/Sports Events Application 文化/体育活动签证申请审核表

学校的详细地址及电话号码准假证明 批准人的姓名及职位

Note: The Embassy / Consulate reserves the right to request additional information/documentation and, if deemed necessary, to interview the applicant/备注: 使领馆保留要求申请人提供补充信息/材料的权利。如若必要,申请者将被要求前往使领馆面试。 Inquiry Officer to choose as appropriate 资料审核员根据适用情况选择: 1. The applicant has confirmed that s/he has no other documents to submit 申请人已经确认她/他不提交其他文件 2. The applicant has submitted the supporting documents above. I have advised him / her that failure to submit all necessary documents may result in the application being refused, but s/he has chosen to proceed with the application. 申请人已经递交了上述文件,我已告知其如不提交所有必要文件可能会导致被拒签,但其选择继续提交申请。 ----------------------------------------- ---------- Name & Signature of Processing Officer Date/日期 (资料受理员签名) ---------------------------------------- Applicant’s Signature(申请人签名)

checklist

Check List 1. What is the age of the youngest worker in this facility? 工厂中年龄最小的工人是多少岁? 2. Are there any work experience programs for school age children? 工厂有帮助学龄儿童获得工作经验的程序吗? 3. Are there restrictions for workers under 18? 工厂有限制聘用18岁以下的工人吗? 4. What procedures does this facility have in place to verify the age of the employees? 工厂用什么程序核实工人的年龄? 5. Are all employees voluntarily working in this facility? 所有工人都自愿在这工厂工作吗? What procedures does this facility has to ensure employees are working voluntarily? 工厂有什幺方式保证工人是自愿工作的? 6. Are there any workers in this facility that are prisoners, have been assigned by the military, or any other branch of government? 工厂有囚犯工或是由军队/政府其他机构分配的工人吗? 7. Are employees free to leave when their work shift ends? 如果工人的轮班时间结束,他们可以自由离开吗? 8. Are guards posted only for normal security reasons? 门卫只是进行正常的守卫工作吗? If so, what are their basic duties? 如果是, 他们基本的工作是什么? 9. How are employees recruited (i.e. newspaper ad, agent, contract?) 工厂通过什么方式聘请工人?(通过报刊广告、职介所、合同?) 10. How are employees disciplined for misconduct or poor performance? 如果工人有不端行为或恶劣的表现会受到什么处分? 11. Do you restrict employment by age, race, ethic group, religion, gender, sexual, orientation, political affiliation, and/or national origin? 工厂会由于工人的年龄、民族、种族、宗教、性别、性取向、政治面貌、和/或者出生地不同而制约工人吗? 12. What is the lowest wage paid by this contractor for trained (i.e. production) employees? For untrained (i.e. janitors, trainees) employees? 训练有素的工人(如生产工人) 的最低薪金是多少? 未经训练的(如门卫, 实习生) 工人的最低薪金又是多少? 13. How are employees paid? (cash/check/auto pay/other) 如何支付工人的薪金? (现金/钞票/自动支付/其他) 14. How is the pay rate calculated? (per hour/piece rate/per day/other) 工人的薪金按什么计算? (每小时/计件率/每天/其他) 15. Is work time documented by a timecard? 工作时间被记录在工时记录卡吗?

(完整版)手机结构设计检查表-checklist-重要

一. 塑胶件 Plastic components 1.有无做干涉检查? If interference test 2.有无做draft检查? If draft test 3.有无透明件背后丝印/喷涂要求?如果有,不能有任何特征在该面上. If requirements of silk printing or painting in the back of the transparency components, and with no features on it. 4.壳体材料, Housing material 5.壳体最小壁厚,侧面是否厚度小于1.2mm. If the least thickness of the side wall of the housing less than 1.2mm 6.设计考虑的浇口位置,有无避位? If anti-interference according with the gate 7.熔接线位置是否会是有强度要求的地方? If weld line with requirements of intensity 8.壁厚突变1.6倍以上处有无逃料措施? If wall thickness break over 1.6 times with slope transition 9.壳体对主板的定位是否足够(至少四点) If housing locating to main board enough(at least with four points) 10.壳体对主板的固定方式,如果是螺丝柱夹持,是否会影响附近的键盘手感? If the screw nipping method of housing to PCBA affect the near key click 11.壳体之间的固定及定位应该有四颗螺丝+每侧面两个卡扣+顶面两卡扣+周边唇边 If housing fixing and locating with four screws and each side with two snap fits and upper side two snap fits and lip around. 12.螺丝是自攻还是NUT?螺径?单边干涉量?配合长度?螺丝头的直径?( 机械螺钉锁3 牙,自攻螺钉5牙以上) If screws manner, such as self-tapping or nut, the screw diameter? One side interference quantity? Matching length? The screw cap diameter?(Over 3 pitch assembly length mechanical screw, over 5 self-tapping screw) 13.螺柱的直径?孔的直径?螺柱壁厚? The screw boss diameter? The boss hole diameter? The thickness of boss wall ? 14.螺丝面是定位面吗?测量基准是什么? If screw surface locating surface? The measure benchmark? 15.唇边的宽度(1/2壁厚左右),高度?之间的配合间隙是否小于0.10mm? The lip width(about1/2 wall thickness),height? If the assembling clearance less than 0.10mm 16.卡扣壁厚/宽度?公卡扣壁厚是否小于0.70mm?卡扣干涉量是否小于0.5mm? The clip thickness/width? If male clip thickness less than 0.70mm, or clip interference less than 0.5mm 17.卡扣导入方向有无圆角或斜角? If clip guide direction with R or bevel

代码大全核心checklist

为了更好的评估代码写的哪里有问题,我把《代码大全》里核心的部分checklist整理出来了,大家可以大概过一遍,不一定每写完一个程序都要一条一条的去检查,但心里应该有这么一 张检查表,在写代码和review代码时自然而然的想起来。 设计 设计是否经过多次迭代,并最终决定了最好的一个? 是否同时使用自上而下和自下而上的方法来解决设计问题? 类与类之间的交互关系是否已经设计为最小化? 设计被划分为层次吗? 你对把这一程序分解成为子程序,包和类的方式感到满意吗? 程序是不是易于维护? 设计是否精简?设计出来的每一个部分都绝对必要吗? 整体而言,你的设计是否有助于最小化偶然性和本质性的复杂度吗? 类的设计 你是否把程序中的类都看做是抽象数据类型了?是否从这个角度评估它们的接口了? 类是否有一个中心目的? 类的命名是否恰当?其名字是否表达了其中新目的? 类的接口是否展现了一致的抽象? 类的接口是否能让人清楚明白的知道如何用它? 类的接口是否抽象,使你能不必顾虑他是如何实现其服务的?你能把类看做黑盒子吗? 类提供的服务是否足够完整,让其它类无需动用其内部数据? 是否已从类中去除无关信息? 是否考虑过把类进一步分解? 在修改类时是否维持了其接口的完整性? 是否把成员的可访问性降到最小? 是否避免暴露类的数据成员? 类是否避免对其使用者,包括其派生类会如何使用它做了假设? 类是否不依赖于其它类?它是松散耦合吗? 继承是否只用来建立一个is a关系?派生类是否遵循了LSP原则。 继承层次是否很浅? 类中是否只有大约七个或者更少的成员? 是否把类直接或者间接调用其他类的子程序的数量减到最少? 类是否在绝对必要时才与其他类写作? 是否在构造函数中初始化了所有的数据成员? 子程序 创建子程序的理由充分吗? 一个子程序中所有适合单独提出的部分是不是已经被提出到单独的子程序中了?

性能测试checklist

如果有朋友想到更多的检查项,也希望可以留言大家一起讨论 1. 开发人员是否提交了测试申请? 2. 测试对象是否已经明确? 3. 测试范围是否已经明确? 4. 本次不被测试的范围是否已经明确? 5. 测试目标是否已经明确? 6. 何时开始性能测试? 7. 何时终止一轮性能测试? 8. 性能测试需要做几轮? 9. 所需的测试环境是什么?是否已经到位并配置完成?(包括硬件、软件、网络等10. 所需的测试工具是什么?是否已经到位并保证可以正常使用? 11. 被测系统的版本是否已经明确?是否已发布?从哪里可以获得?是否已经部署成功? 12. 被测系统的相关功能是否已经正确实现? 13. 压力点是否已经明确?响应时间的计算方式是否已经明确? 14. 本次测试工作参考的文档有哪些? 15. 场景是否已经设计完成并记录在场景管理文档中? 16. 每个场景是否有明确的测试意图、前置条件和详细的设置? 17. 脚本是否已经录制并调试通过? 18. 是否已经明确了哪些地方需要参数化?

19. 是否已经明确了各个参数的取值方式? 20. 是否已经为参数化的部分准备了必须的数据? 21. 是否已经准备了相应历史数据量? 22. 是否已经准备了相应的数据恢复方法?(例如准备一个SQL 语句用来恢复数据环境 23. 在Controller 中对多VU 、多次迭代的情况是否已经调试通过? 24. 在Controller 中Result 的路径设置是否正确? 25. 在Controller 中检查脚本选择是否正确? 26. 在Controller 中检查VU 数量设置是否正确? 27. 在Controller 中检查集合点是否禁用/启用? 28. 在Controller 中检查VU 加载策略是否设置正确? 29. 在Controller 中检查迭代次数是否设置正确? 30. 在Controller 中检查迭代间隔设置是否正确? 31. 在Controller 中检查日志是否禁用/启用? 32. 在Controller 中检查Think_Time 是否回放? 33. 在Controller中检查是否为UNIX服务器和Load Generator机添加了资源监视器并确认可以收到性能数据? 34. 在Controller 中检查是否为其他必要的资源添加了资源监视器,并确认可以收到性能数据(例如Oracle , WebSphere ? 35. 在Controller中检查Load Generator机是否可以连上? 36. 检查场景管理文档中是否添加了新的“场景执行情况”并, 记录了运行

各国EMC和安规标准更新列表

Standards updated list Page 1 of 7 Title of the standards 标准名称 Amendment/edition of standards 标准标准版本及修订版本及修订 Date of publish (DOP) 过渡使用日期 Date of withdrawal (DOW) 强制使用日期 Remark 备注 (常见产品类别常见产品类别)) EN standards EN 55011:2007 2007-11-01 2009-11-01 EN 55011:2007+A2: 2007 2007-11-01 2009-11-01 EN 55011:2009 2010-09-01 2012-09-01 Industrial, scientific and medical (ISM) radio-frequency equipment – radio disturbance characteristics – limits and methods of measurement EN 55011:2009+A1:2010 2011-04-01 2013-07-01 工业、科学和医疗(ISM)用射频设备,比如电磁炉,微波炉,电焊机, 超声波设备等 EN 55013: 2001+A1 :2003 2004-01-01 2006-04-01 Sound and television broadcast receivers and associated equipment – Radio disturbance characteristics – Limits and methods of measurement EN 55013: 2001+A1 :2003+A2 :2006 2006-12-01 2009-03-01 EN 55020: 2002 + A1: 2003 + A2: 2005 2005-11-01 2008-02-01 Sound and television broadcast receivers and associated equipment – Immunity characteristics – Limits and methods of measurement EN 55020:2007 2007-09-01 2009-12-01 声音和电视广播接收机. 比如: FM 收音机, CD Player DVD Player,模拟/数字电视机,功 放等 EN55014-1:2006 2007-06-01 2009-09-01 Electromagnetic compatibility – Requirements for household appliances, electric tools and similar apparatus – Part 1: Emission EN 55014-1: 2006+A1: 2009 2010-02-01 2012-05-01 EN55014-2:1997+A1: 2001 2002-09-01 2004-12-01 Electromagnetic compatibility – Requirements for household appliances, electric tools and similar apparatus – Part 2: Immunity – Product Family Standard EN55014-2:1997 +A1: 2001+A2: 2008 2009-06-01 2011-09-01 家用电器及电动工具及类似电器。比如冰箱,空调,加热器。搅拌机, 榨汁机,马达,风机等。 Limits and methods of measurement of radio disturbance characteristics of electrical lighting EN55015:2006+A1: 2007 2008-05-01 2010-05-01 照明电器,包括灯具,变压器,交

PCB-Checklist

PCB-Checklist

阶段项 目 序 号 检查内容EDA 设计 EDA 复审 EDA 确认 备注 资料输入阶段1.在流程上接收到的资料是否齐全(包括:原理图、*.brd文件、料单、PCB设计说明以及PCB 设计或更改要求、标准化要求说明、工艺设计说明文件) 2.3确认PCB模板是最新的 3.确认模板的定位器件位置无误 4.PCB设计说明以及PCB设计或更改要求、标准化要求说明是否明确 5.4确认外形图上的禁止布放器件和布线区已在PCB模板上体现 6.比较外形图,确认PCB所标注尺寸及公差无误, 金属化孔和非金属化孔定义准确 7.5 确认PCB模板准确无误后最好锁定该结构文件,以免误操作被移动位置 布局后检查 阶段器 件 检 查 8.确认所有器件封装是否与公司统一库一致,是否已更新封装库(用viewlog检查运行结果)如 果不一致,一定要Update Symbols 9.母板与子板,单板与背板,确认信号对应,位置对应,连接器方向及丝印标识正确,且子板有 防误插措施,子板与母板上的器件不应产生干涉 10.元器件是否100% 放置 11.打开器件TOP和BOTTOM层的place-bound,查看重叠引起的DRC是否允许 12.M ark点是否足够且必要 13.较重的元器件,应该布放在靠近PCB支撑点或支撑边的地方,以减少PCB的翘曲 14.与结构相关的器件布好局后最好锁住,防止误操作移动位置 15.压接插座周围5mm范围内,正面不允许有高度超过压接插座高度的元件,背面不允许有元件或 焊点 16.确认器件布局是否满足工艺性要求(重点关注BGA、PLCC、贴片插座) 17.金属壳体的元器件,特别注意不要与其它元器件相碰,要留有足够的空间位置 18.接口相关的器件尽量靠近接口放置,背板总线驱动器尽量靠近背板连接器放置 2

Checklist清单

Checklist for Private Visitor Temporary Resident Visa Application (Visiting family or friends) 12/2012

Note/注意: All Documents in Chinese must be accompanied by an English or French translation. 所有中文文件必须附有英文或法文的翻译件。 If you intend to travel to the United States during your visit to Canada, you do not need a multiple -entry visa in order to re-enter Canada directly from the United States during the period for which you were originally admitted to Canada. 如果申请人想在访问加拿大期间前往美国,在加拿大合法停留期限之内从美国再次进入加拿大不需要一个多次入境签证。 Please note that the processing fee is non-refundable for any application that is withdrawn or refused. 请注意任何撤销或被拒签的申请受理费用都不予退还。 Inquiry Officer to delete as appropriate (资料审核员根据适用情况选择) 1.The applicant has confirmed that s/he has no other documents to submit 申请人已经确认她/他不提交其他文件 OR 或者 2.The applicant has submitted the supporting documents above. I have advised him / her that failure to submit all necessary documents may result in the application being refused, but s/he has chosen to proceed with the application. * 申请人/代理已获悉所有在文件袋右边的申请材料将不会被返还。 --------------------------------------------- --------------- Name & Signature of Inquiry Officer (资料审核员签名) Date/日期: ---------------------------------------- Applicant’s Signature (申请人签名)

checklist

2015 DANGEROUS GOODS CHECKLIST FOR A NON-RADIOACTIVE SHIPMENT The recommended checklist appearing on the following pages is intended to verify shipments at origin. Never accept or refuse a shipment before all items have been checked. Is the following information correct for each entry? SHIPPERS DECLARATION FOR DANGEROUS GOODS(DGD) YES NO*N/A 1.Two copies in English and in the IATA format including the air certification statement[8.1.1,8.1.2,8.1.6.12]..................................................................................................................## 2.Full name and address of Shipper and Consignee[8.1.6.1,8.1.6.2]...........................................................## 3.If the Air Waybill number is not shown,enter it.[8.1.6.3].............................................................................# 4.The number of pages shown[8.1.6.4]..........................................................................................................## 5.The non-applicable Aircraft Type deleted or not shown[8.1. 6.5].................................................................## 6.If full name of Airport or City of Departure or Destination is not shown,enter it.[8.1.6.6and8.1.6.7] Information is optional...................................................................................................................................## 7.The word“Radioactive”deleted or not shown[8.1.6.8]................................................................................## Identification 8.UN or ID Number,preceded by prefix[8.1.6.9.1,Step1].............................................................................## 9.Proper Shipping Name and the technical name in brackets for asterisked entries[8.1.6.9.1,Step2]........## 10.Class or Division,and for Class1,the Compatibility Group,[8.1.6.9.1,Step3]..........................................## 11.Subsidiary Risk,in parentheses,immediately following Class or Division[8.1.6.9.1,Step4]......................### 12.Packing Group[8.1.6.9.1,Step5].................................................................................................................### Quantity and Type of Packing 13.Number and Type of Packages[8.1.6.9.2,Step6].......................................................................................## 14.Quantity and unit of measure(net,or gross followed by“G”,as applicable)within per package limit[8.1.6.9.2,Step6]..................................................................................................................................## 15.When different dangerous goods are packed in one outer packaging,the following rules are complied with: –Compatible according to Table9.3.A.....................................................................................................###–UN packages containing Division6.2[5.0.2.11(c)].................................................................................###–“All packed in one(type of packaging)”[8.1.6.9.2,Step6(f)].................................................................###–Calculation of“Q”value must not exceed1[5.0.2.11(g)&(h);2.7.5.6;8.1.6.9.2,Step6(g)]...............### 16.Overpack –Compatible according to Table9.3.A.[5.0.1.5.1]...................................................................................###–Wording“Overpack Used”[8.1.6.9.2,Step7].........................................................................................###–If more than one overpack is used,identification marks shown and total quantity of dangerous goods[8.1.6.9.2,Step7].........................................................................................................................### Packing Instructions 17.Packing Instruction Number[8.1.6.9.3,Step8]............................................................................................## 18.For lithium batteries in compliance with Section IB,“IB”follows the packing instruction[8.1.6.9.3, Step8]..........................................................................................................................................................### Authorizations 19.Check all verifiable special provisions.The Special Provision Number if A1,A2,A4,A5,A51,A81,A88, A99,A130,A190,A191[8.1.6.9.4,Step9]...................................................................................................### 20.Indication that governmental authorization is attached,including a copy in English and additional approvals for other items under[8.1.6.9.4,Step9]......................................................................................### Additional Handling Information 21.The mandatory statement shown for self-reactive and related substances of Division4.1 and organic peroxides of Division5.2,or samples thereof,for PBE and for fireworks[8.1.6.11.1, 8.1.6.11.2,8.1.6.11.3and8.1.6.11.5]...........................................................................................................### https://www.sodocs.net/doc/0317788295.html, and Telephone Number of a responsible person for Division6.2Infectious Substance shipment[8.1.6.11.4]....................................................................................................................................### https://www.sodocs.net/doc/0317788295.html, and Title(or Department)of Signatory,Place and Date indicated and Signature of Shipper[8.1.6.13,8.1.6.14and8.1.6.15].....................................................................................................## 24.Amendment or alteration signed by Shipper[8.1.2.6].................................................................................###

相关文档

- 软件编程规范总则CHECKLIST

- 检查单(checklist)

- checklist_图文

- PCB Checklist

- 硬件设计checklist

- 性能测试checklist

- Checklist模板实用

- PPAP检查清单Checklist(中英文)

- 模具验收checklist(中英文)

- 评审检查单(Checklist-Review)-revise

- checklist

- Checklist清单

- 版本发布CheckList

- 旅游出行必备checklist

- checklist模板

- 产品结构设计等方面的checklist

- 项目checklist模板

- checklist

- 原理图checklist

- PPAP检查清单Checklist(中英文)